Micropore machining method for metal or alloy product

A technology of micro-hole processing and alloying, which is used in metal processing equipment, manufacturing tools, welding/welding/cutting items, etc., and can solve problems such as insufficient depth of limit, large ablation aperture, and many thick cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

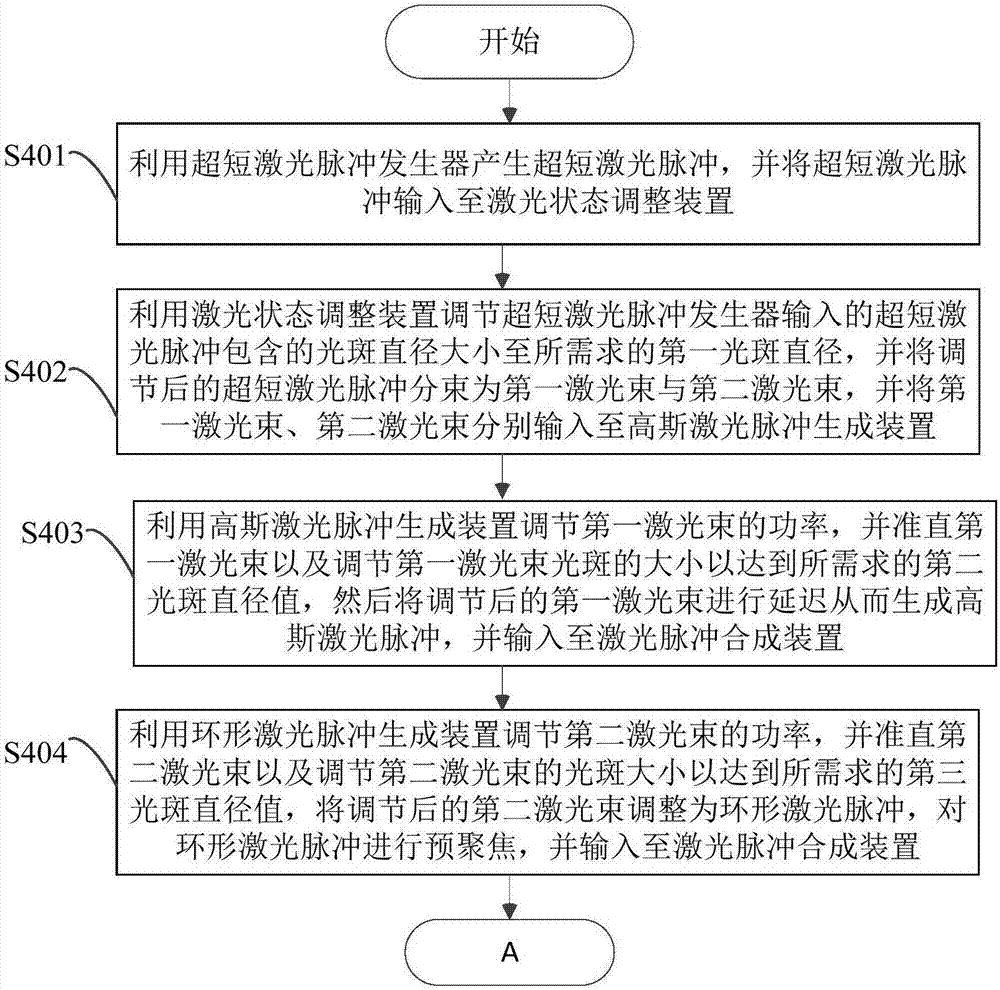

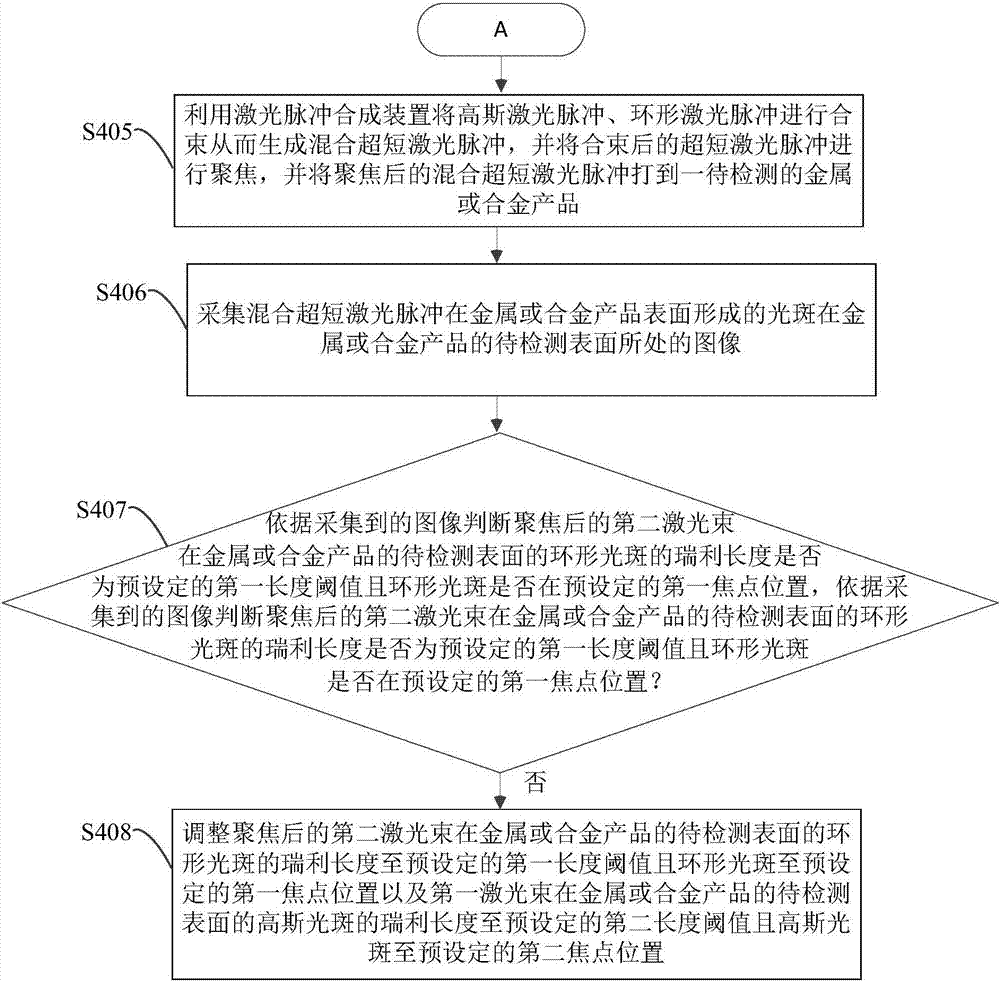

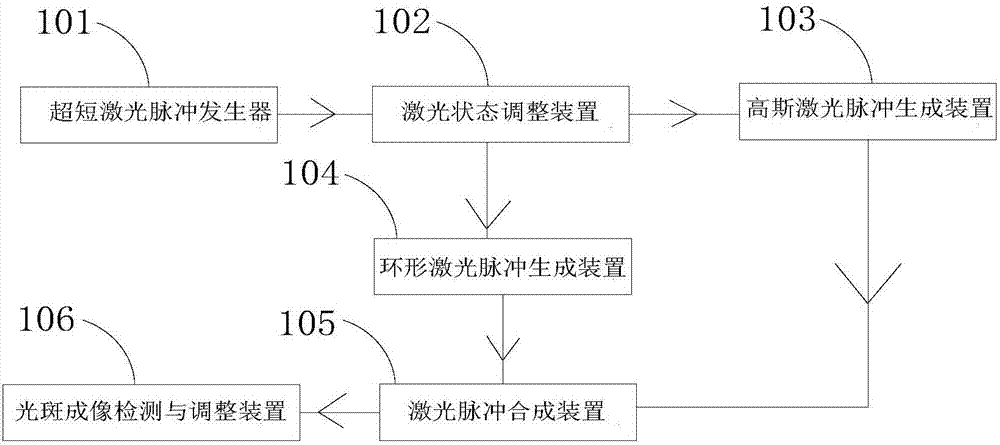

[0061] see figure 1 , figure 2 , the embodiment of the present invention is a metal or alloy product micropore processing method, which is a metal or alloy product processing system. Such as image 3 As shown, the metal or alloy product processing system includes an ultrashort laser pulse generator 101 , a laser state adjustment device 102 , a Gaussian laser pulse generation device 103 , a ring laser pulse generation device 104 and a laser pulse synthesis device 105 . The metal or alloy product micropore processing method includes:

[0062] Step S101 : Utilize the ultrashort laser pulse generator 101 to generate ultrashort laser pulses, and output the ultrashort laser pulses to the laser state adjustment device 102 .

[0063] Among them, in this embodiment, the various parameters of the femtosecond ultrashort laser pulse are: center wavelength 800nm, laser linewidth 40nm, laser pulse width 120fs, repetition frequency 1kHz, output power 1W, power jitter less than 5%, laser ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com