Oxygen evolution Fe-doped cobalt diselenide@N-CT compound catalyst and preparation method and application thereof

A composite catalyst and catalyst technology, applied in the field of electrocatalysis, can solve the problems of low activity and conductivity, and achieve the effects of enhanced catalytic performance, simple preparation method and high catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

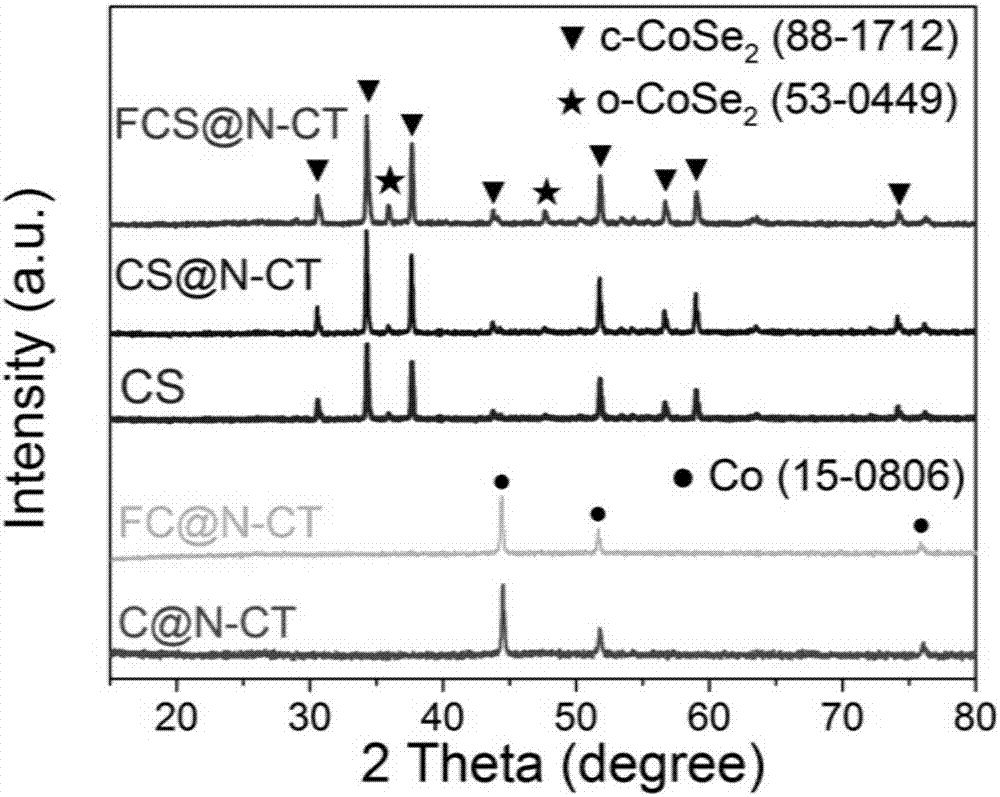

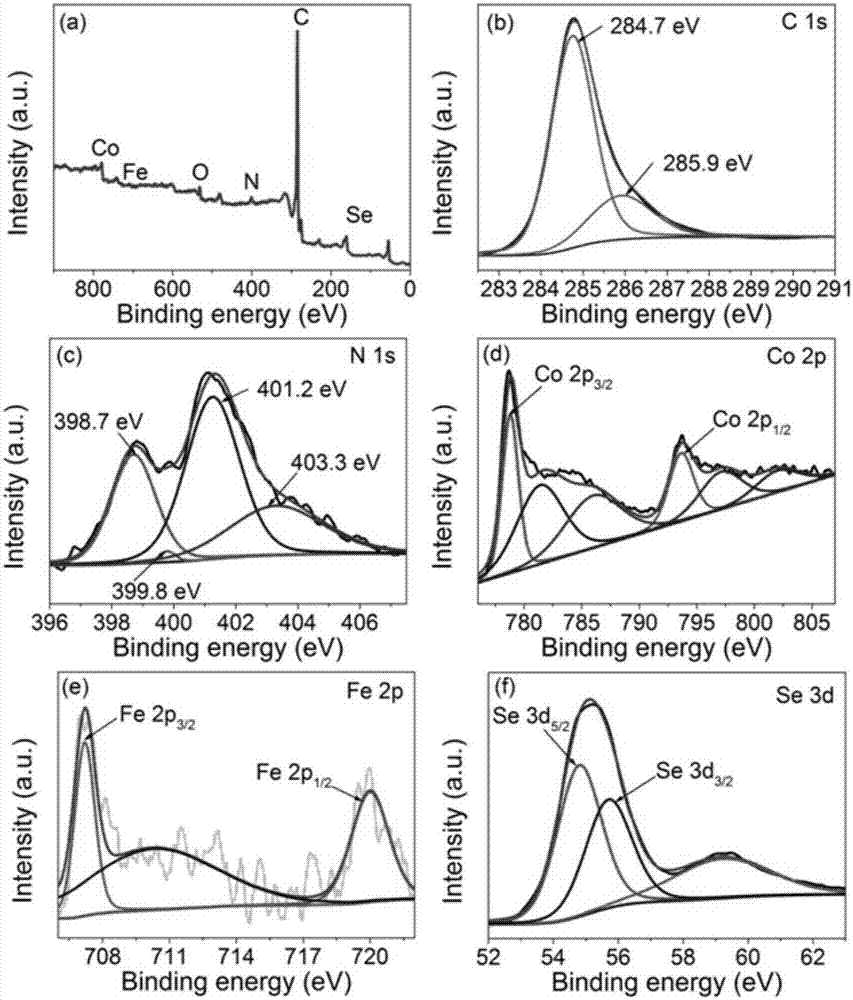

Embodiment 1

[0028] Preparation of Co@N-CT (denoted as C@N-CT):

[0029] A synthetic method using two-step heat treatment, the specific process is as follows: 0.5g Co(Ac) 2 4H 2 O and 10 g of urea were dissolved in 5 mL of deionized water at 80 °C, and evaporated under stirring for about 40 min; then the solid mixture was transferred to a 100 mL porcelain crucible, and the temperature was raised to 450 °C at a heating rate of 5 °C / min in a muffle furnace. ℃, keep warm for 1h, and cool naturally; grind the product evenly and put it in high-purity N 2 Heated to 800°C at a rate of 10°C / min in the atmosphere, kept for 1 hour, and obtained after natural cooling.

[0030] Preparation of Fe-doped Co nanoparticles coated with N-doped carbon nanotubes (referred to as FC@N-CT):

[0031] 0.45g Co(Ac) 2 4H 2 O, 0.081g Fe(NO 3 ) 3 9H 2 O and 10 g of urea were dissolved in 5 mL of deionized water at 80 °C, and the remaining steps were the same as those for the synthesis of C@N-CT above.

[0032...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com