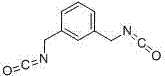

Preparation method of XDI molecular imprinting solid phase extraction column filling material

A solid-phase extraction column and molecular imprinting technology are applied in the field of preparation of m-xylylene isocyanate molecularly imprinted solid-phase extraction filling materials, which can solve the problem that plastic products cannot enter the EU market, and achieve good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation of m-xylylene dimethyl isocyanate molecularly imprinted solid-phase extraction column packing material, the specific raw material dosage is shown in Table 1.

[0020] Table 1 Reaction raw materials and dosage

[0021] Reaction material Molecular weight (g / mol) Reaction dosage m-xylylene isocyanate 166.17 43.1mg Methacrylate 86.09 104.3mg Ethylene glycol dimethacrylate 198.22 1.89 mL Dibenzoyl peroxide 242.23 73mg Porogen (ethyl acetate) 88.11 18mL

[0022] 1. the reaction raw material template molecule m-xylylene isocyanate, functional monomer methacrylic acid, cross-linking agent ethylene glycol dimethacrylate and porogen ethyl acetate are added successively according to the consumption of table 1 Put it into a two-neck bottle with a grinding mouth, ultrasonic 35min, mix evenly, then add 73mg of dibenzoyl peroxide, ultrasonic degassing for 15min, nitrogen gas for 35min, seal it, react in 40℃ oil b...

Embodiment 2

[0025] The preparation of m-xylylene dimethyl isocyanate molecularly imprinted solid-phase extraction column packing material, the specific raw material consumption is shown in Table 2.

[0026] Table 2 Reaction raw materials and dosage

[0027] Reaction material Molecular weight (g / mol) Reaction dosage m-xylylene isocyanate 166.17 43.1mg Methacrylate 86.09 125mg Ethylene glycol dimethacrylate 198.22 2.83 mL Dibenzoyl peroxide 242.23 73mg Porogen (ethyl acetate) 88.11 40mL

[0028] 1. Add reaction raw material template molecule m-xylylene dimethyl isocyanate, functional monomer methacrylic acid, crosslinking agent ethylene glycol dimethacrylate and porogen acetonitrile and water to the grinding port in turn according to the consumption in Table 2 In a two-neck bottle, ultrasonic 35min, after mixing evenly, then add 73mg of dibenzoyl peroxide, ultrasonic degassing 15min, nitrogen gas 35min, seal, react in 80 ℃ oil bath fo...

Embodiment 3

[0031] The preparation of m-xylylene dimethyl isocyanate molecularly imprinted solid-phase extraction column packing material, the specific raw material dosage is shown in Table 3.

[0032] Table 3 Reaction raw materials and dosage

[0033] Reaction material Molecular weight (g / mol) Reaction dosage m-xylylene isocyanate 166.17 43.1mg Methacrylate 86.09 125mg Ethylene glycol dimethacrylate 198.22 2.83 mL Dibenzoyl peroxide 242.23 61mg Porogen (ethyl acetate) 88.11 40mL

[0034] 1. Add the reaction raw material template molecule m-xylylene dimethyl isocyanate, functional monomer methacrylic acid, crosslinking agent ethylene glycol dimethacrylate and porogen ethyl acetate to the grinding port in sequence according to the dosage in Table 3 In a two-neck bottle, ultrasonic 30min, after mixing evenly, then add 61mg of dibenzoyl peroxide, ultrasonic degassing 15min, nitrogen gas 35min, seal, react in 60 ℃ oil bath for 24h, to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com