Microwave carbonization equipment

A microwave and equipment technology, applied in the field of microwave carbonization equipment, to prevent overheating damage and ease resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

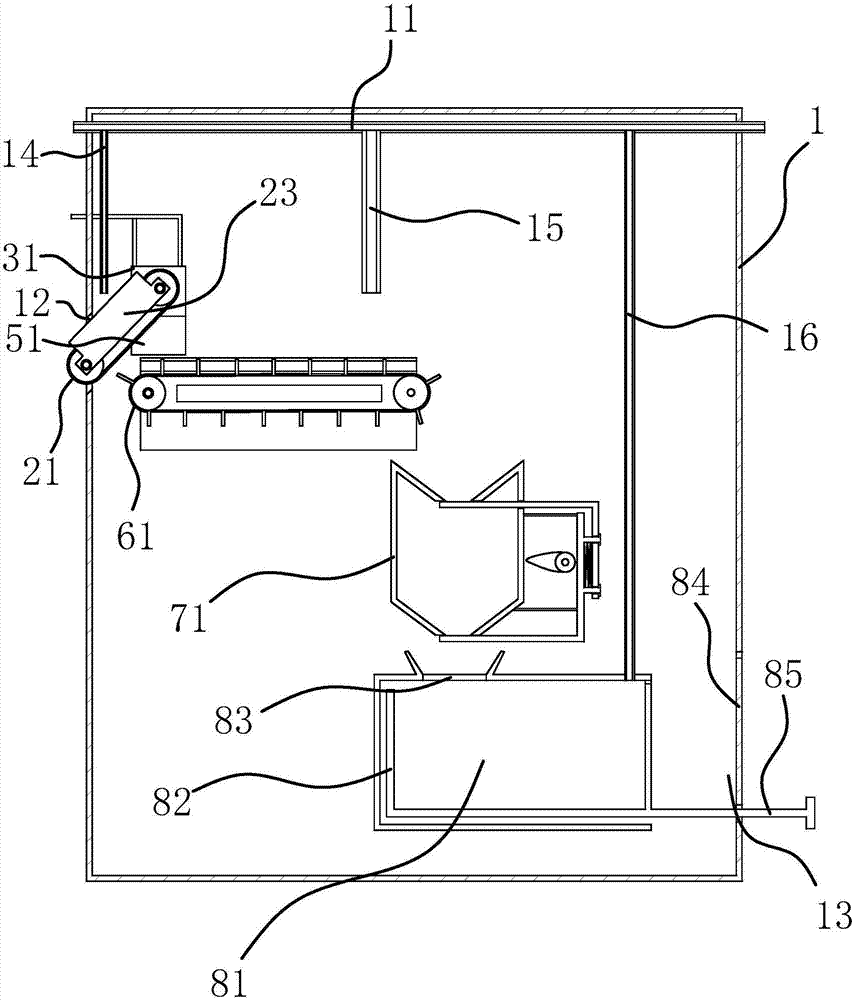

[0046] Such as figure 1 As shown, the microwave carbonization equipment includes a sealed box body 1 and a main gas pipe 11 that fills the box body with carbon dioxide gas. The box body 1 is provided with a material inlet 12 and a material outlet 13. The feeding device is located in the box body 1, and the box body 1 is sequentially provided with a wood shredder, a sawdust mixer, a molding machine, a microwave carbonization device, a charcoal activation device and a discharge device, and the discharge device is arranged at the discharge port 13; The feeding port 12 is provided with a bronchus one 14 located in the casing 1, and the casing 1 is also provided with a bronchus two 15 and a bronchus three 16, and the bronchus one 14,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com