Power-driven transplanter

A transplanter and electric technology, applied in the field of agricultural machinery, can solve the problems of difficult to popularize and use in a large area, difficult to meet agronomic requirements, difficult to use crops, etc., and achieve the effects of wide applicability, light weight, and damage reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the content of the present invention is not limited thereto.

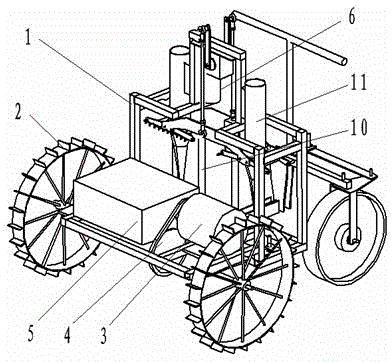

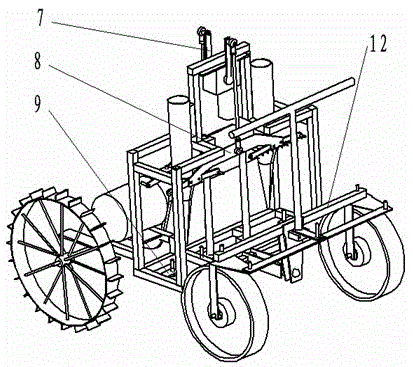

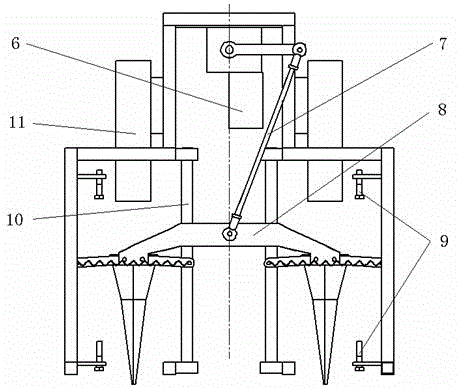

[0020] see figure 1 , 23. The electric transplanting machine includes a frame 1 with traveling wheels, a drive motor 3 and a battery 5 installed in the front of the frame 1, and a steering mechanism 12 hinged to the rear of the frame, which are respectively installed in the middle of the frame 1 The two seedling guide tubes 11 on both sides of the upper end and the transplanting motor 6 in the middle position, the crank motion mechanism 7 and the transplanting mechanism 8 below the transplanting motor 6; the front part of the frame 1 is a wheel frame structure, and the middle part is a raised The support structure of the transplanting mechanism, the tail is a tailstock structure connected with the steering mechanism, and the middle part of the elevated transplanting mechanism support has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com