Treatment method and system of cyanogens-containing organic waste gas

A treatment method, a technology for organic waste gas, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of complex process and high treatment cost, and achieve the effect of reducing operating load and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

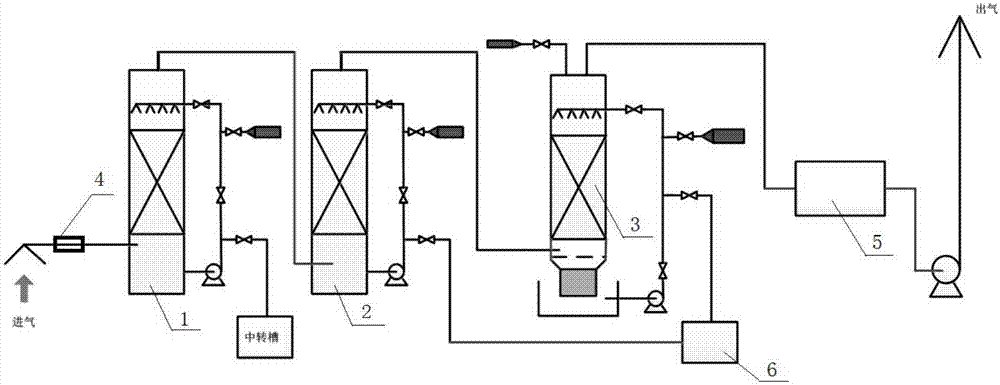

[0041] Such as figure 1 The shown processing system includes a cooler 4, an acid spray absorption tower 1, an alkali spray absorption tower 2, and a catalytic oxidation tower 3, which are connected in sequence. The air outlet of the previous device is connected to the air inlet of the next device for catalytic oxidation The tower 3 is composed of two parts: an upper packing layer and a bottom catalyst bed. The gas outlet of the catalytic oxidation tower 3 is in communication with the atmosphere. The upper part of the catalytic oxidation tower 3 is filled with ceramics; the lower part of the catalyst is a supported catalyst, with activated carbon as the carrier and copper as the active component.

[0042] The catalytic oxidation tower is connected with the chlorine dioxide preparation device 6 and the transfer tank, the auxiliary catalytic oxidation reaction tank, and the auxiliary oxidant adding device. The flow path is also provided with pH and concentration detectors (not show...

Embodiment 2

[0045] The cyanidation reaction process of the disperse blue B60 production process in a factory produced mixed waste gas containing hydrogen cyanide, DMF, and higher concentrations of ammonia and aniline. Of which hydrogen cyanide 330-350mg / m 3 , Ammonia 180mg / m 3 , TVOC is about 1200mg / m 3 .

[0046] Exhaust gas at 2000m 3 The flow rate per hour enters the condenser, the condensation temperature is -10℃, the condensed waste gas enters the pickling tower, and the hydrogen chloride concentration is 10% countercurrent absorption, the liquid to gas ratio is 6, and the hydrogen cyanide content after absorption is about 280mg / m 3 , The ammonia content is about 12mg / m 3 , TVOC is about 980mg / m 3 .

[0047] The acid-washed exhaust gas enters the alkali spray tower and is absorbed countercurrently with the mass fraction of 12% sodium hydroxide. The liquid-gas ratio of the alkali spray tower is 7, the exhaust gas flow rate is 0.8m / s, and the absorption temperature is 35°C. After hydrogen c...

Embodiment 3

[0051] Disperse blue B60 production process in a factory produced mixed waste gas containing hydrogen cyanide and low-concentration ammonia during the cyanidation reaction process. Of which hydrogen cyanide 220-250mg / m 3 , Ammonia 140mg / m 3 , TVOC is about 1000mg / m 3 .

[0052] Exhaust gas at 1800m 3 The flow rate per hour enters the condenser, the condensation temperature is -10℃, the condensed waste gas enters the pickling tower, and the hydrogen chloride concentration is 10% countercurrent absorption, the liquid to gas ratio is 6, and the hydrogen cyanide content after absorption is about 180mg / m 3 , The ammonia content is about 22mg / m 3 , TVOC is about 870mg / m 3 .

[0053] The acid-washed exhaust gas enters the alkali spray tower and is absorbed countercurrently with the mass fraction of 12% sodium hydroxide. The liquid-gas ratio of the alkali spray tower is 6.5, the exhaust gas flow rate is 0.6m / s, and the absorption temperature is 30°C. After hydrogen cyanide content is about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com