Filter element structure and processing method thereof

A processing method and filter element technology, applied in the field of water purification and filtration, to achieve the effects of cost saving, simple processing method and assembly process, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

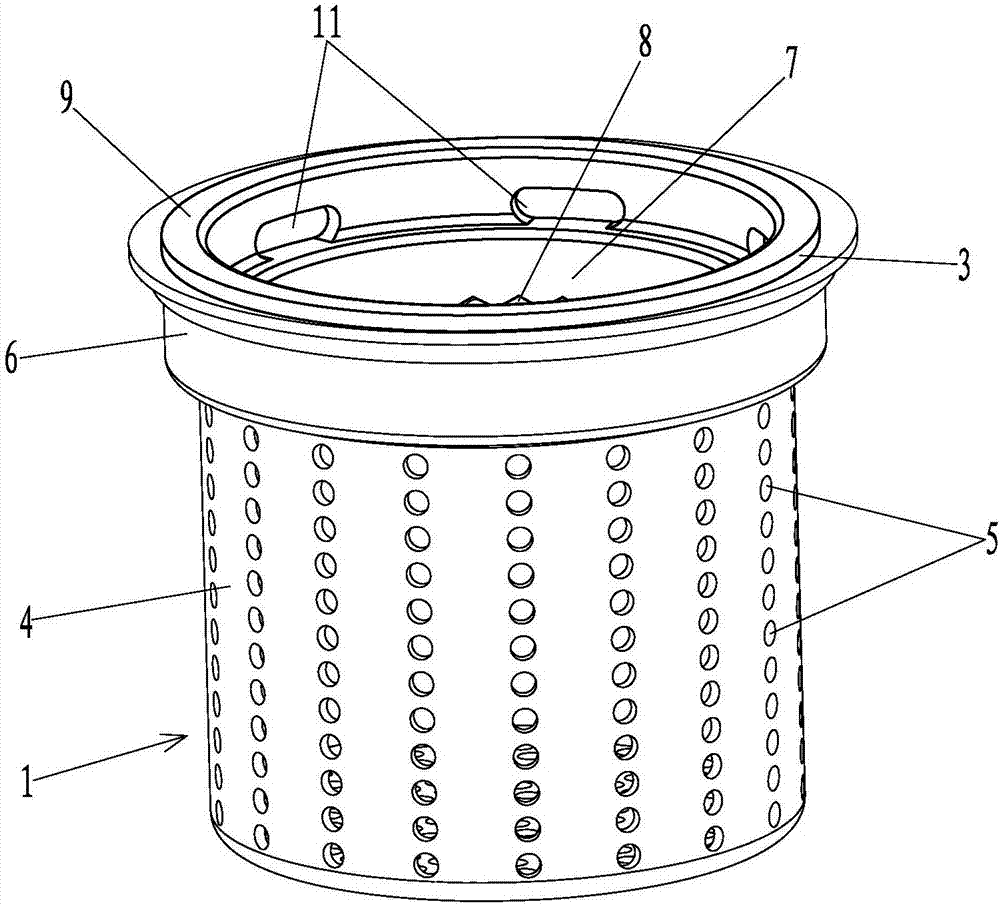

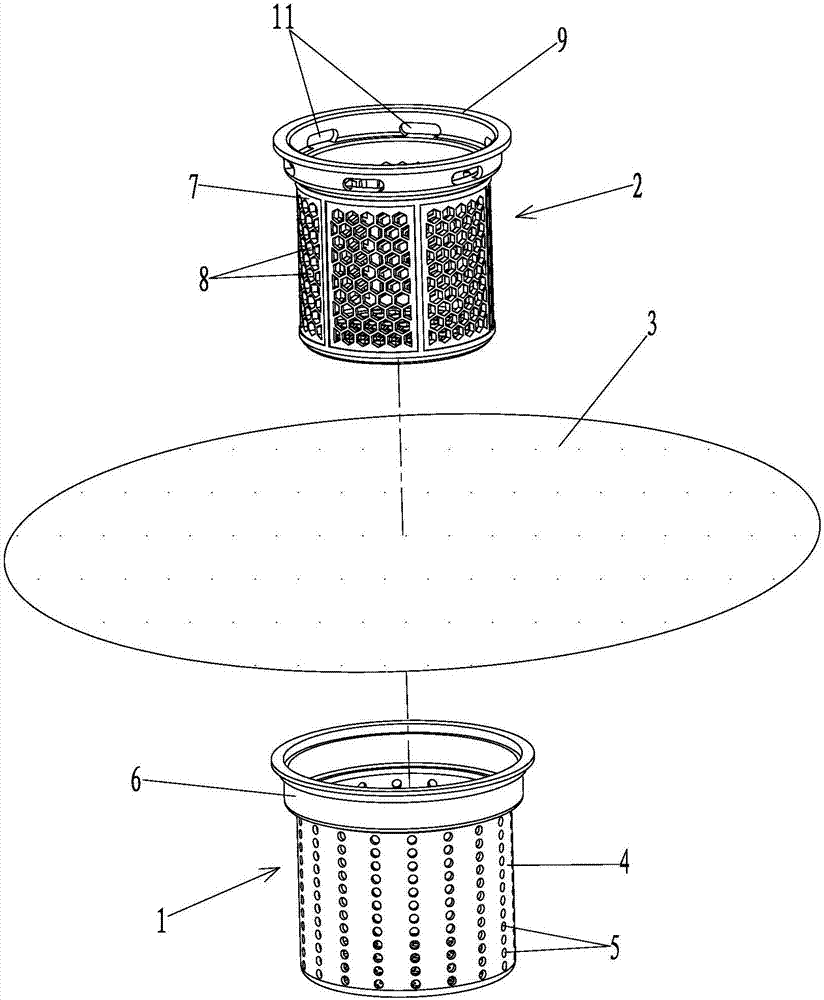

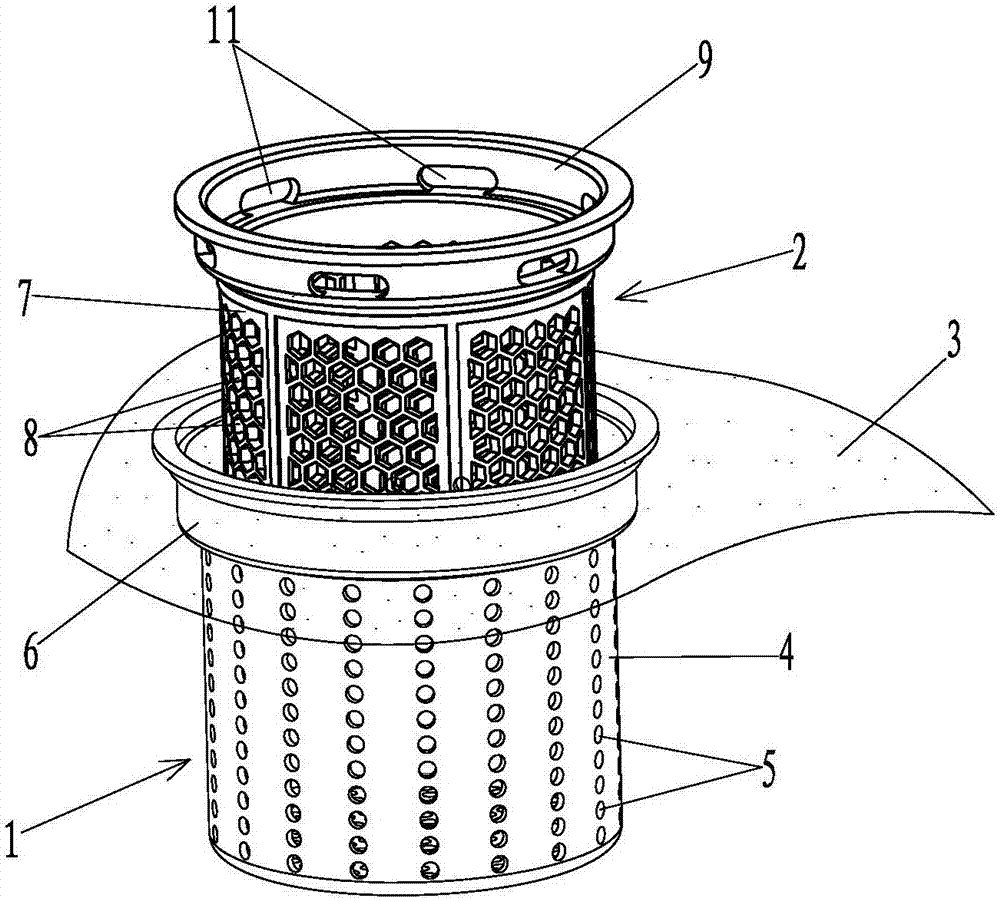

[0034] Such as figure 1 The three-dimensional structural schematic diagram of Embodiment 1 of the filter element structure of the present invention is shown, including a cylindrical or conical first filter cartridge skeleton 1 and a second filter cartridge that are nested together and closed with a flat or raised spherical surface at the bottom end. Skeleton 2, the first filter cartridge frame 1 is sleeved on the outer surface of the second filter cartridge frame 2, the first filter cartridge frame 1 and the second filter cartridge frame 2 are both made of plastic or metal materials. A nuclear pore membrane 3 is sandwiched between the first filter cartridge frame 1 and the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com