Method for preparing ZrO2 bone repair biological ceramic scaffold material through gradient dip-coating of HA

A technology of bioceramics and scaffold materials, applied in coating, tissue regeneration, medical science, etc., can solve the problems of excessive strength of dense bodies, stress shielding, etc., achieve firm osseointegration, increase contact surface area, and meet immediate stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] 1.1 Pretreatment of model organic foam materials

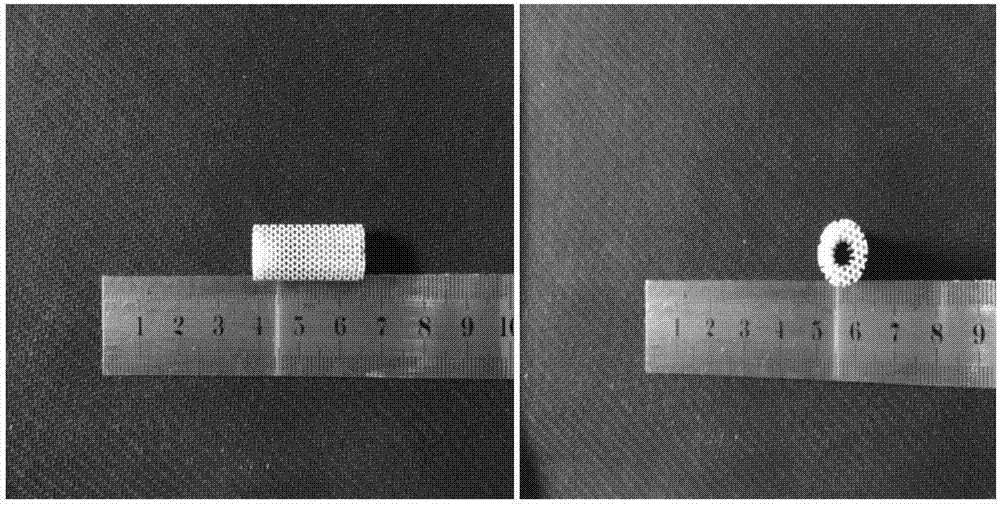

[0077] Polyurethane is used as the foam model material, because the polyurethane material has a network interlayer, and the existence of the interlayer makes it difficult for the slurry to enter the interior of the foam model, which will cause plugging, uneven distribution of the slurry, and poor porosity of the sintered foam ceramics. and poor mechanical properties. Therefore, it is necessary to open the membrane first, so that the organic foam forms a three-dimensional network structure. In addition, the organic foam model has poor hydrophilicity and small wetting angle, so the slurry is not easy to adsorb. In order to improve the slurrying performance of the foam model material, pretreatment is required. Cut the organic polyurethane foam material into a semi-cylindrical shape with a height of 24 cm and a radius of 9 cm, soak it in a 15 wt% sodium hydroxide solution at 60 °C for 3.5 h, rub it repeatedly with clean w...

Embodiment 2

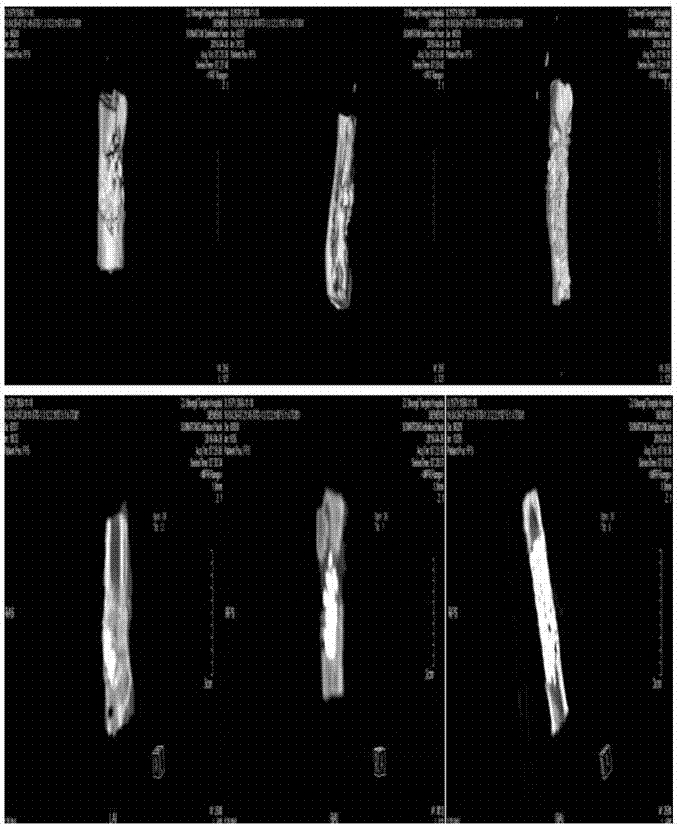

[0086] 1.1 Animal model of femoral shaft defect

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com