Gamma-aminobutyric acid (GABA)-enriched mulberry leaf powder and preparation method thereof

A technology of aminobutyric acid and mulberry leaf powder, which is applied to the bacteria used in food preparation, the function of food ingredients, lactobacillus, etc., can solve the problem of limited GABA content in mulberry leaves, and achieve the effect of increasing the added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1 A preparation method of mulberry leaf powder rich in γ-aminobutyric acid

[0047] A preparation method of mulberry leaf powder rich in gamma-aminobutyric acid, comprising the steps of:

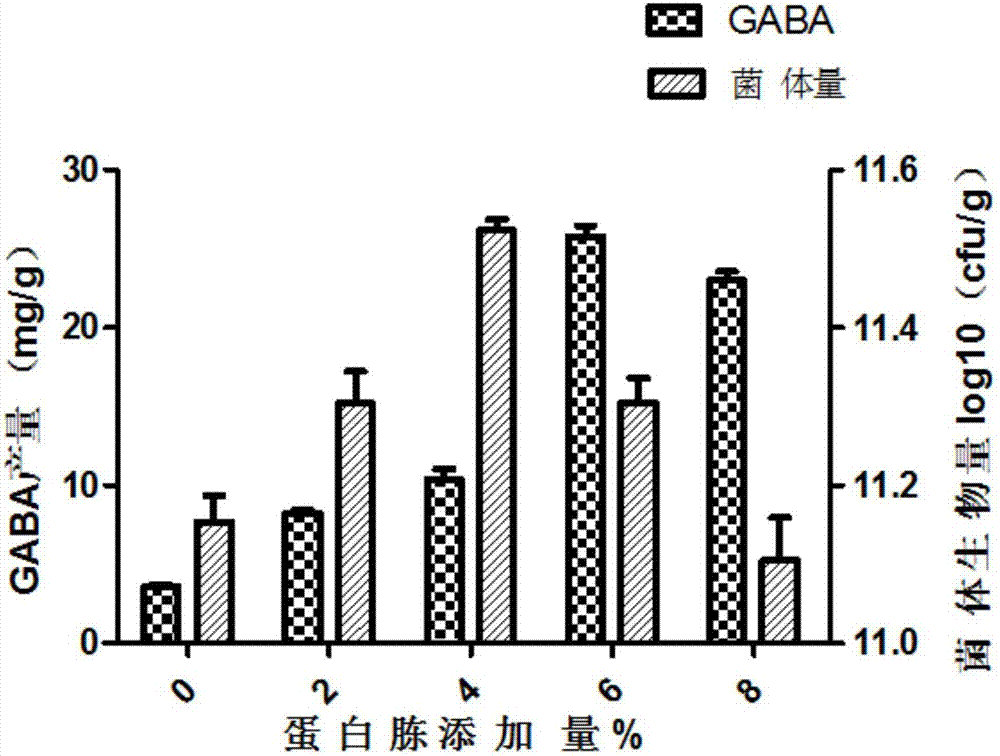

[0048] S1. Fresh mulberry leaves are washed, dried, and crushed through a 1000-mesh sieve to obtain mulberry leaf powder; take mulberry leaf powder as the substrate, add 6% peptone accounting for the total weight of mulberry leaf powder, and 1.6% K 2 HPO 4 , 1.0% L-sodium glutamate and 60% water, after mixing, sterilize at 120°C for 20 minutes, cool for later use;

[0049] S2. Inoculate the activated Lactobacillus pentosus SS6 strain into the MRS liquid medium, and culture it statically at 37°C for 8 hours to obtain the seed liquid, and inoculate the seed liquid into the mixed mulberry leaf powder in step S1, the inoculation amount is 9% , and then fermented at 30°C for 36h;

[0050] S3. Drying and pulverizing the fermented mulberry leaf powder under vacuum conditions at 55...

Embodiment 2

[0051] Example 2 Optimization of the preparation process of mulberry leaf powder rich in γ-aminobutyric acid

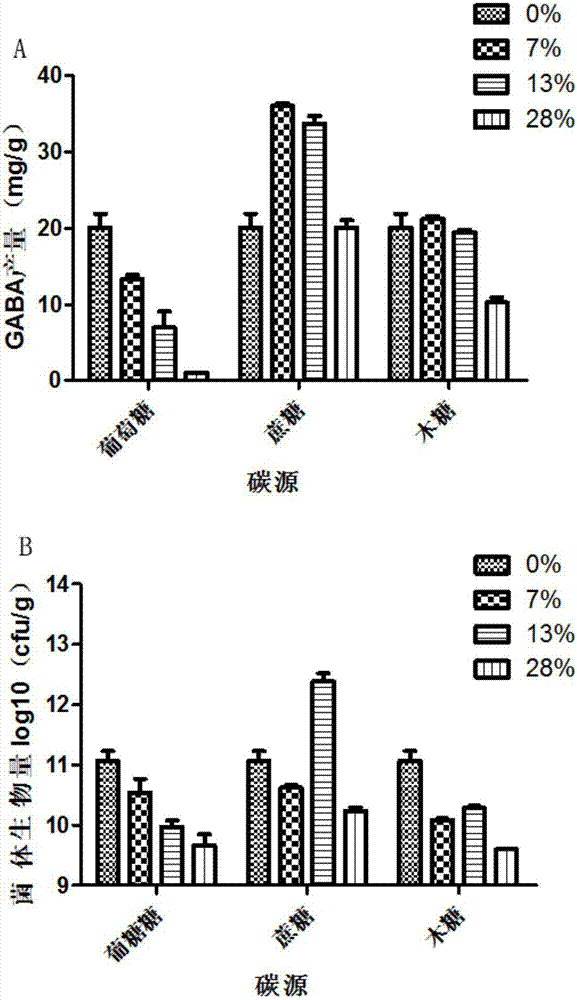

[0052] 1. Optimization of carbon source addition in mixed mulberry leaf powder

[0053]S1. Fresh mulberry leaves were washed, dried, and crushed through a 1000-mesh sieve to obtain mulberry leaf powder; using mulberry leaf powder as a matrix, carbon sources (glucose, sucrose, xylose) were added according to 4 conditions, respectively 0%, 7%, 13%, 28% (w / w, the same below). Add 2% peptone as nitrogen source, add 0.42% K 2 HPO 4 , the initial water content is 60%;

[0054] S2. Inoculate the activated Lactobacillus pentosus SS6 strain into the MRS liquid medium, and cultivate it statically at 37°C for 8 hours as the seed liquid, inoculate the seed liquid into the mixed mulberry leaf powder in step S1, the inoculation amount is 5%, Ferment at 35°C for 36h.

[0055] S3. Drying and pulverizing the fermented mulberry leaf powder to obtain mulberry leaf powder rich in γ-...

Embodiment 3

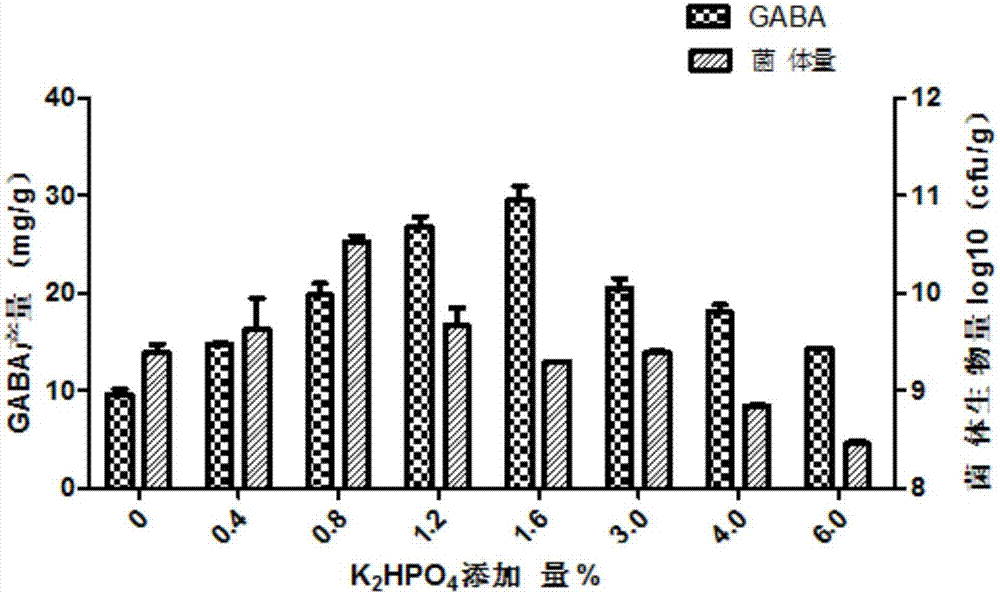

[0064] K2HPO4 Addition Optimization in Mixed Mulberry Leaf Powder of Embodiment 3

[0065] 1. K in the mixed mulberry leaf powder 2 HPO 4 Addition optimization

[0066] S1. Fresh mulberry leaves are washed, dried, and crushed through a 1000-mesh sieve to obtain mulberry leaf powder; using mulberry leaf powder as the matrix, add K according to 8 conditions 2 HPO 4 , respectively 0%, 0.4%, 0.8%, 1.2%, 1.6%, 3.0%, 4.0%, 6.0% (w / w, the same below). Add 7% sucrose, add 6% peptone, and the initial water content is 60%;

[0067] S2. Inoculate the activated Lactobacillus pentosus SS6 strain into the MRS liquid medium, and cultivate it statically at 37°C for 8 hours as the seed liquid, inoculate the seed liquid into the mixed mulberry leaf powder in step S1, the inoculation amount is 5%, Ferment at 35°C for 36h.

[0068] S3. Drying and pulverizing the fermented mulberry leaf powder to obtain mulberry leaf powder rich in γ-aminobutyric acid.

[0069] 2. Results

[0070] The resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com