High attitude stereo planting device and planting method

A three-dimensional planting and planting module technology, applied in the fields of botanical equipment and methods, horticulture, container cultivation, etc., can solve problems such as crop yield reduction, and achieve the effects of reducing construction costs, being convenient to use, and improving tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

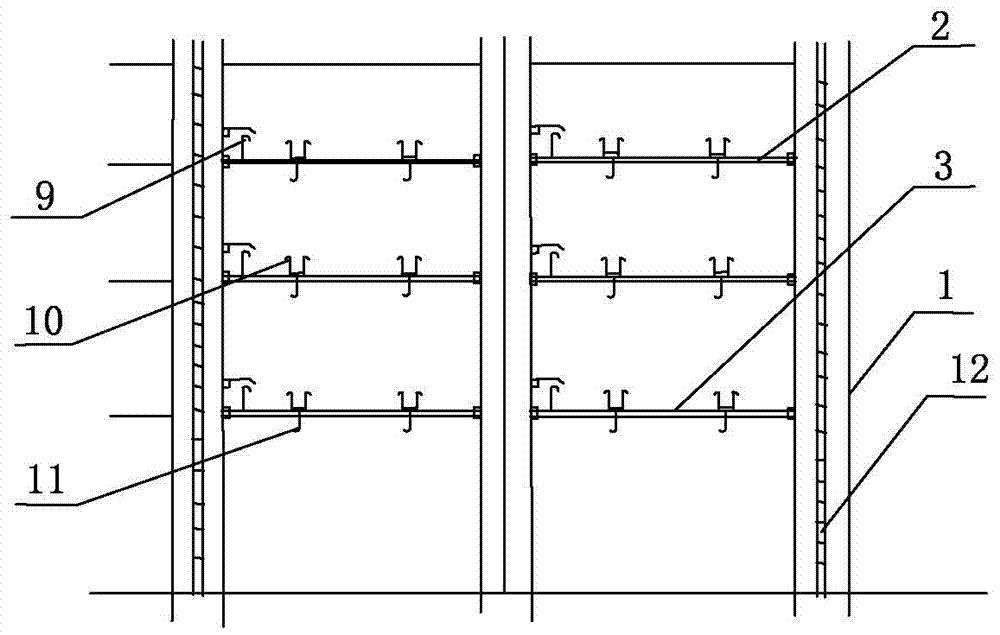

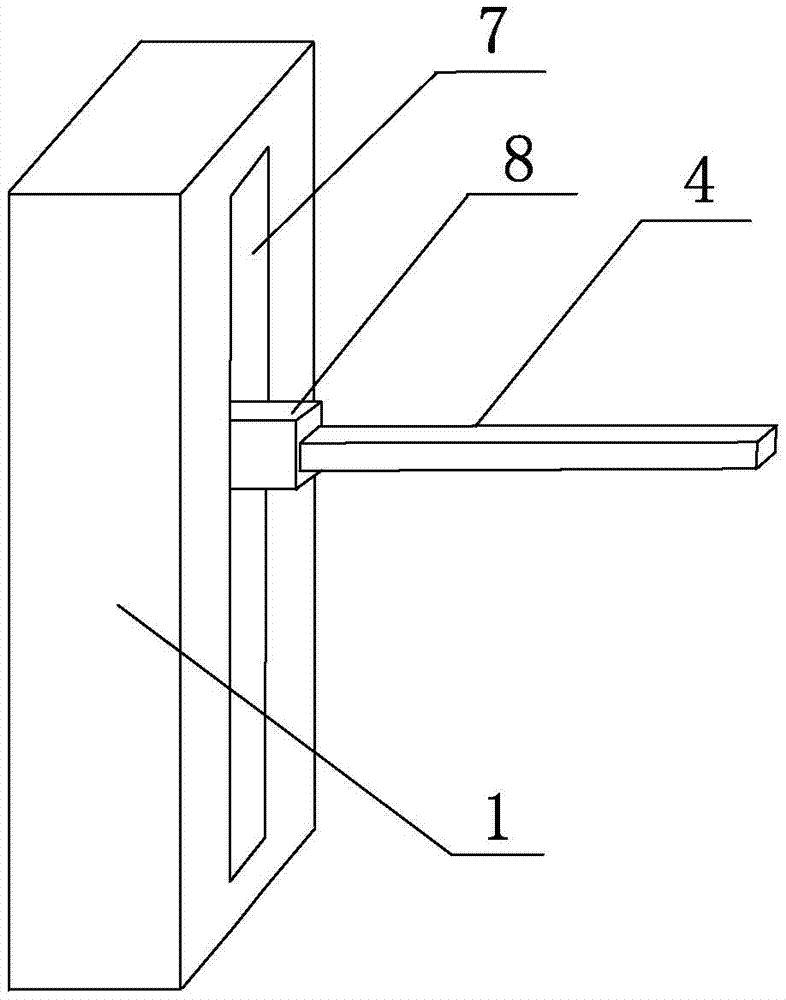

[0037] see figure 1 , a high-altitude three-dimensional planting device, including a vertical support 1 fixed on the ground and a multi-layer planting platform 2 movably connected with the vertical support 1, the planting platform 2 is perpendicular to the vertical support 1, and the planting platform 2 is Multiple planting modules 3 are provided.

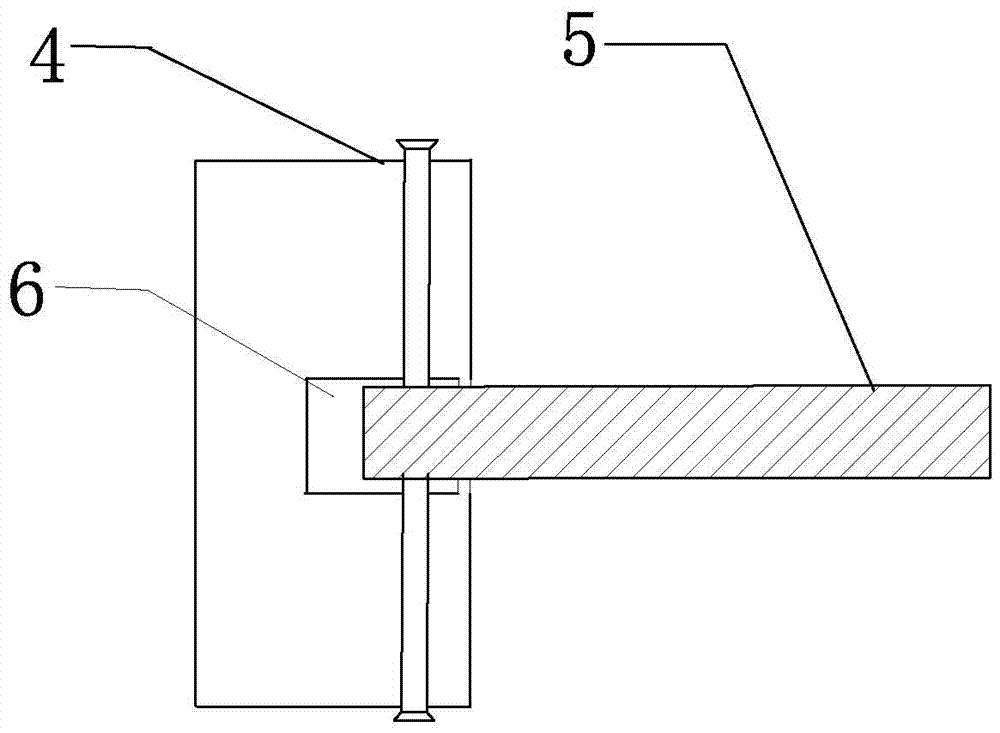

[0038] see Figure 1-2 , further, the planting platform 2 includes a plurality of crossbeams 4 movably connected with the vertical support 1 and a support plate 5 connected with the plurality of crossbeams 4, the crossbeams 4 are provided with horizontal installation grooves 6, and the support The edge of the plate 5 is fixed in the mo...

Embodiment 2

[0047]The aluminum alloy used in the aluminum alloy expanded stencil is composed of the following raw materials in mass percentage: Zn 1.5%, Sc: 0.04%, Si: 0.5%, Fe: 0.45%, Mn: 0.5%, Mg: 0.3%, Ti: 0.15%, Cr: 0.2%, Mo: 0.05%, Sr: 0.02%, Ce: 0.02%, and the balance is Al.

[0048] The preparation method of the aluminum alloy includes the following steps: adding Zn, Sc, Si, Fe, Mn, Mg, Ti, Cr, Mo and Sr in proportion to a melting furnace for melting, and when the melting temperature is raised to 670°C, press Proportion by weight percentage, adding the pre-prepared Ce-Al master alloy block and Sc-Al master alloy to smelt for 80 minutes, after the Ce-Al master alloy block and Sc-Al master alloy are completely melted, the temperature is raised to 740°C, accounting for the total weight of the charge 0.4% hexachloroethane, press the bell jar into the 2 / 3 of the alloy melt surface to refine the alloy liquid, and stir slowly in the furnace for 12 minutes; let it stand for 10 minutes, and...

Embodiment 3

[0052] The aluminum alloy used in the aluminum alloy expanded stencil is composed of the following raw materials in mass percentage: Zn: 2.2%, Sc: 0.07%, Si: 0.3%, Fe: 0.6%, Mn: 0.8%, Mg: 0.2%, Ti : 0.2%, Cr: 0.3%, Mo: 0.02%, Sr: 0.02%, Ce: 0.02%-0.03%, and the balance is Al.

[0053] The preparation method of the aluminum alloy includes the following steps: adding Zn, Sc, Si, Fe, Mn, Mg, Ti, Cr, Mo and Sr in proportion to the melting furnace for melting, and when the melting temperature is raised to 690°C, press Proportion by weight percentage, adding the pre-prepared Ce-Al master alloy block and Sc-Al master alloy block respectively for smelting for 60 minutes, after the Ce-Al master alloy block, Ce-Al master alloy block and Sc-Al master alloy are completely melted, Raise the temperature to 720°C, press the bell jar into the 2 / 3 place below the surface of the alloy melt with 0.6% hexachloroethane to refine the alloy liquid, and stir slowly in the furnace for 18 minutes; Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com