Safety diaphragm for secondary battery and preparation method thereof

A secondary battery and safety technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of side reactions between positive and negative electrodes and electrolyte, affecting the ionic conductivity of the diaphragm, affecting the permeability of the diaphragm, etc. Ease of implementation, improved safety, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

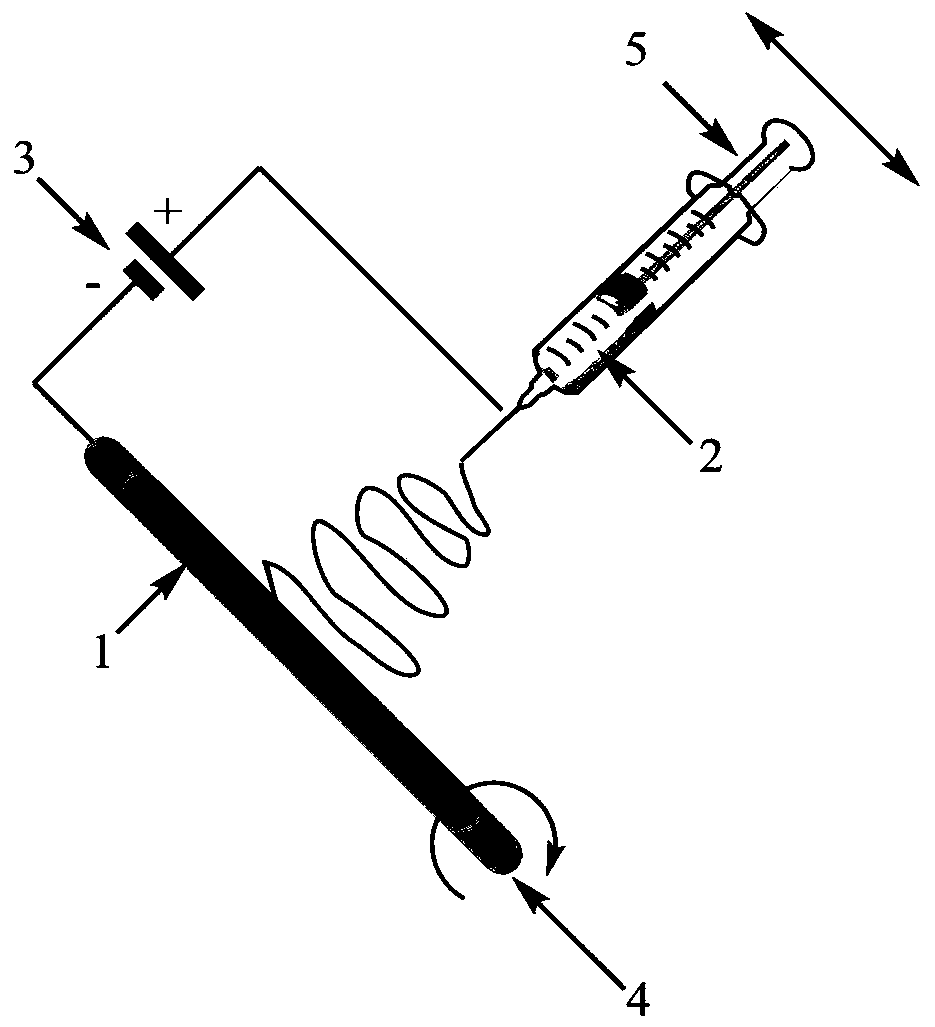

[0028] Such as figure 1 As shown, the preparation method of the secondary battery safety separator provided in this embodiment 1 includes the following steps:

[0029] Spinning solution configuration process:

[0030] At room temperature, 1 g of ethylene-vinyl acetate copolymer (EVA, 40% VA) heat-sensitive material was dissolved in a mixed solution of 7 mL of hexafluoroisopropanol and 7 mL of chloroform as a spinning solute, and stirred evenly to obtain an electrospinning solution ;

[0031] Electrospinning process:

[0032] Wrap the polyimide (PI) base film 1 on the receiving cylindrical connection device, connect it to the negative pole of the high voltage power supply 3, and connect it to the negative high voltage; put the spinning solution 2 into a 10mL disposable syringe 5, and connect it to the high voltage power supply 3 connected to the positive electrode, connected to the positive high voltage, and started electrospinning.

[0033] The parameters are set as: posit...

Embodiment 2

[0039] The procedure is the same as that in Example 1, except that the spinning solution is configured by dissolving 1 g of vinyl acetate (EVA, 40% VA) spinning solute in a mixed solution of 6 mL of hexafluoroisopropanol and 6 mL of chloroform.

[0040] Ionic conductivity and safety test are the same as in Example 1.

Embodiment 3

[0042] Same as the procedure in Example 1, the difference is that the configuration of the spinning solution is that 2g polybutylene succinate (PBS) spinning solute is dissolved in 4mL hexafluoroisopropanol, 4mL chloroform and 2mL o-chloro in a mixed solution of benzaldehyde.

[0043] Ionic conductivity and safety test are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com