Outer sheath material and high-temperature-ceramization ceramic charging cable manufactured from same

A high-temperature ceramic and outer sheath technology, which is used in the field of high-voltage resistant ceramic charging cables and high-temperature ceramics, can solve the problems of poor high-voltage resistance, high manufacturing costs, losses, etc., and achieves good heat insulation and fire insulation. The effect of small equipment investment and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

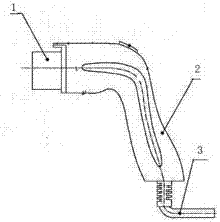

[0029] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0030] Such as figure 1 As shown, the present invention provides an outer sheath of a high-temperature ceramic ceramic charging cable, which is made of ceramic low-smoke, halogen-free, flame-retardant polyolefin water and fire-resistant ceramic materials, and the water-fire-resistant ceramic materials include silicone rubber and Composite ceramic powder, composite ceramic powder includes ceramic body material and ceramic glaze body material, ceramic body material includes by weight: 100 parts of silicon dioxide, 40-50 parts of boron oxide, 20-30 parts of zirconia, oxide 20-30 parts of aluminum, 3-5 parts of strontium oxide, ceramic glaze body materials include: 100 parts of silicon dioxide, 20-30 parts of potassium oxide, 40-50 parts of aluminum oxide, 15-25 parts of calcium oxide, 10-20 parts of zinc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com