Vibration monitoring system for engine's high temperature crankcase

A vibration monitoring system and engine technology, applied to vibration measurement in solids, measuring vibration, measuring devices, etc., can solve the problems of increasing test cost and difficulty, high-temperature sensors are expensive, monitoring, signal processing and fault diagnosis are difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

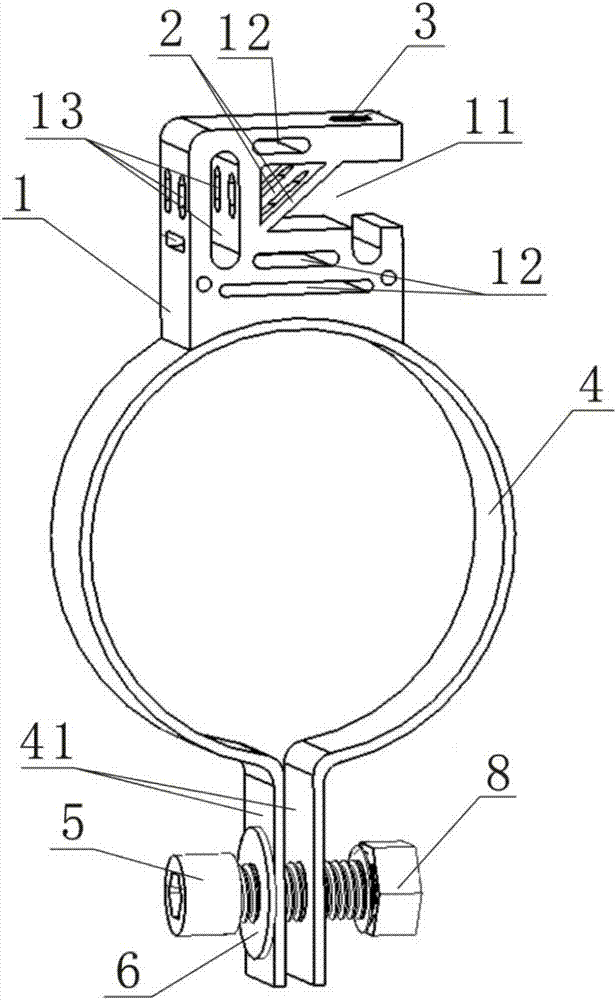

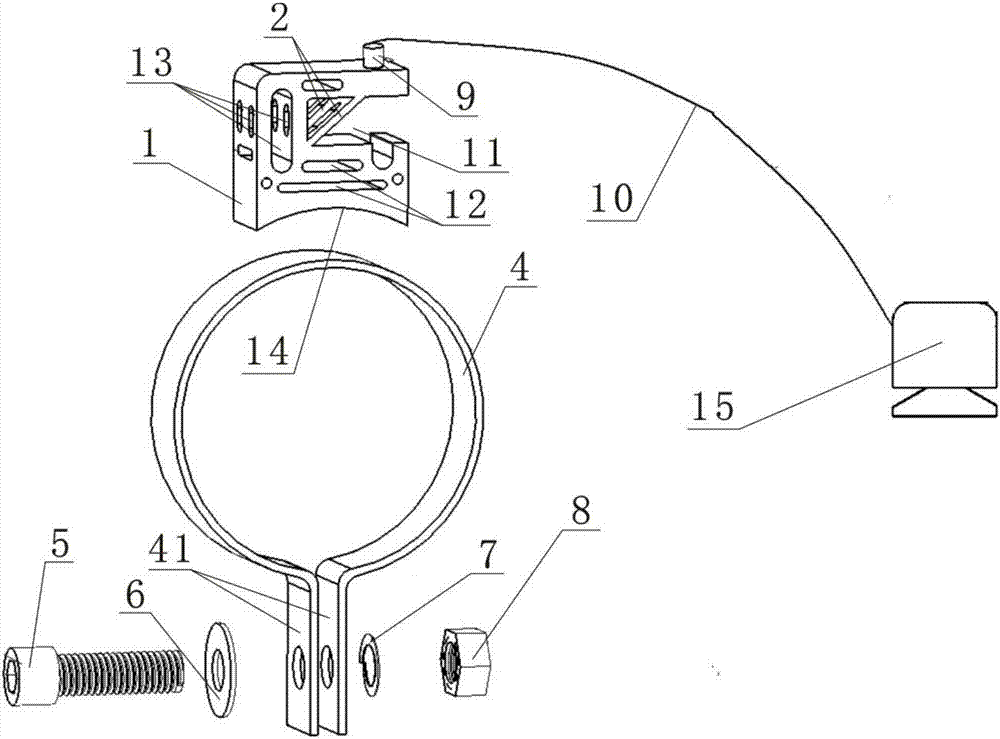

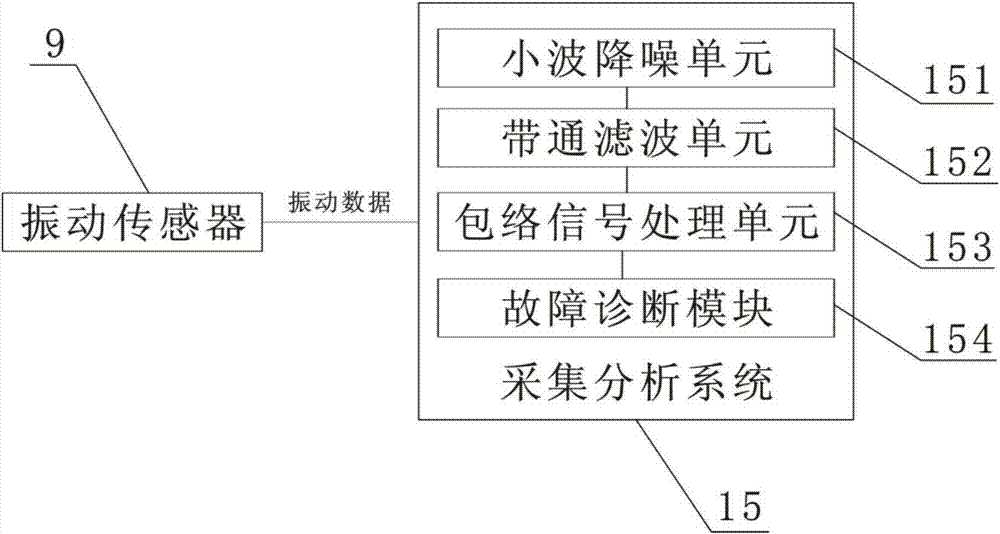

[0020] Such as figure 1 , figure 2 , image 3 As shown, a vibration monitoring system for high-temperature casing of an engine includes a cooling mounting table 1 and a clamp band 4, the clamp band 4 forms a non-closed circular shape, and the lower end of the clamp band 4 has a non-closed connection The end 41 has a bolt hole on the non-closed connection end 41, and a bolt 5 is installed in the bolt hole of the non-closed connection end 41, and the bolt 5 passes through the bolt hole of the non-closed connection end 41 and is threadedly connected with the nut 8, A number of spring washers 7 are set on the bolt 5; the bottom of the heat dissipation installation platform 1 has an arc-shaped installation end surface 14, and the arc-shaped installation end surface 14 of the heat dissipation installation platform 1 is fixedly connected with the top of the clamp band 4, and the middle part of the heat dissipation installation platform 1 There is a heat insulation slot 11, and sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com