Self-oil gathering enhancing type roller path surface and preparation method thereof

An enhanced, self-collecting oil technology, applied in mechanical equipment, metal material coating process, coating and other directions, can solve the problems of fatigue damage of parts, damage to the surface integrity of materials, damage to materials, etc., to achieve the principle of scientific , Ingenious design, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The main structure of the surface of the self-oil-collecting enhanced raceway involved in this embodiment is: a coating layer 101 and an oleophilic layer 102. The oleophilic layer 102 is located in the middle of the raceway. The width of 101 is 4mm-10mm, the thickness is 80-100nm, and the width of the middle lipophilic layer 102 is 0.3mm-1mm. The material of the coating layer 101 is an organosilane material containing fluorine. Under the action of surface tension, the lubricating oil has a tendency to flow to the center, which ensures effective lubrication improvement even when the remaining amount of lubricating oil is small.

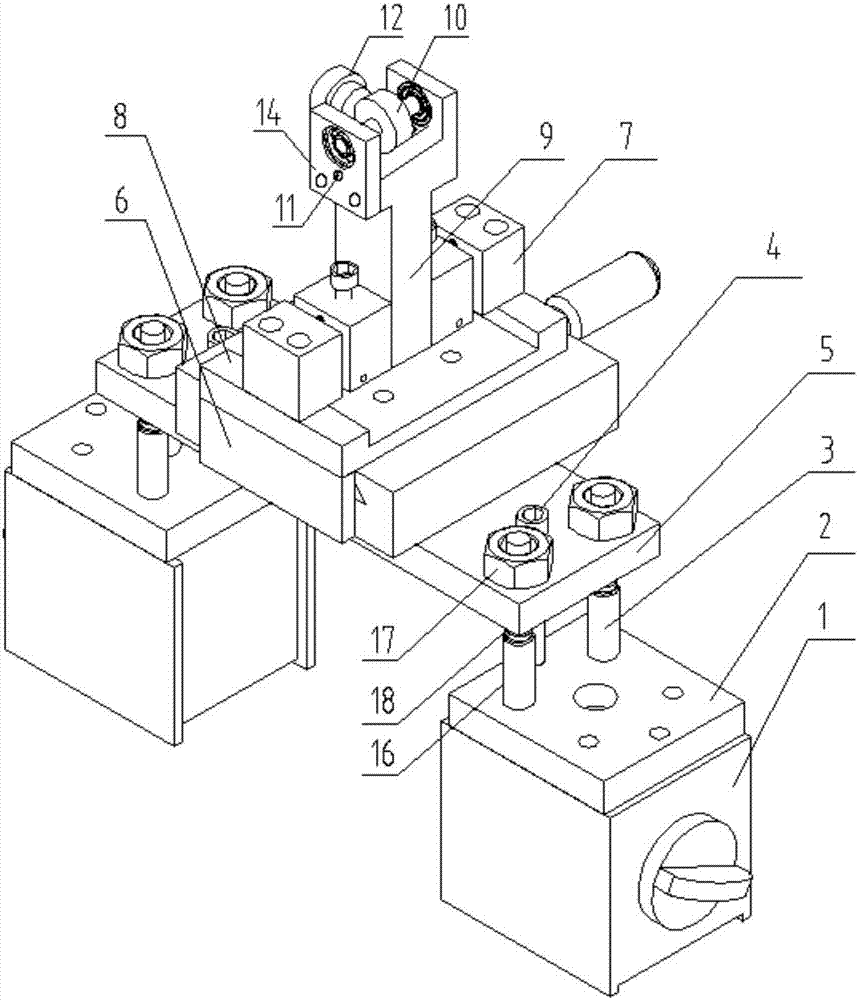

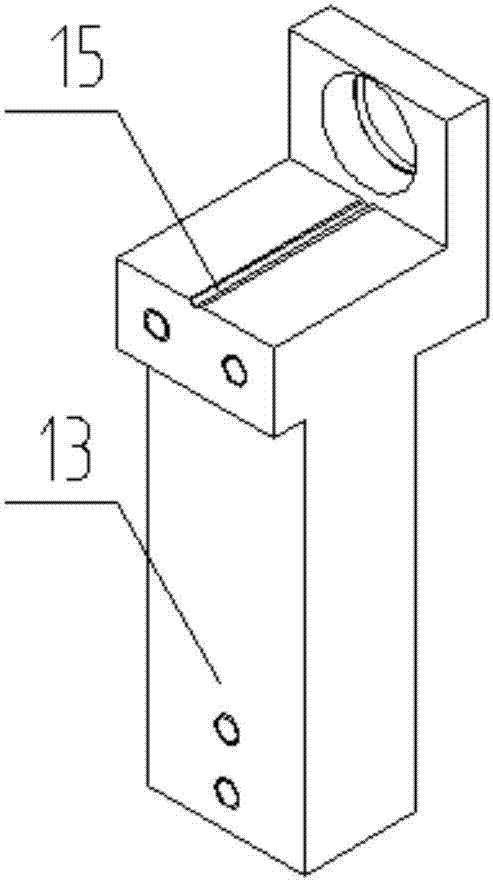

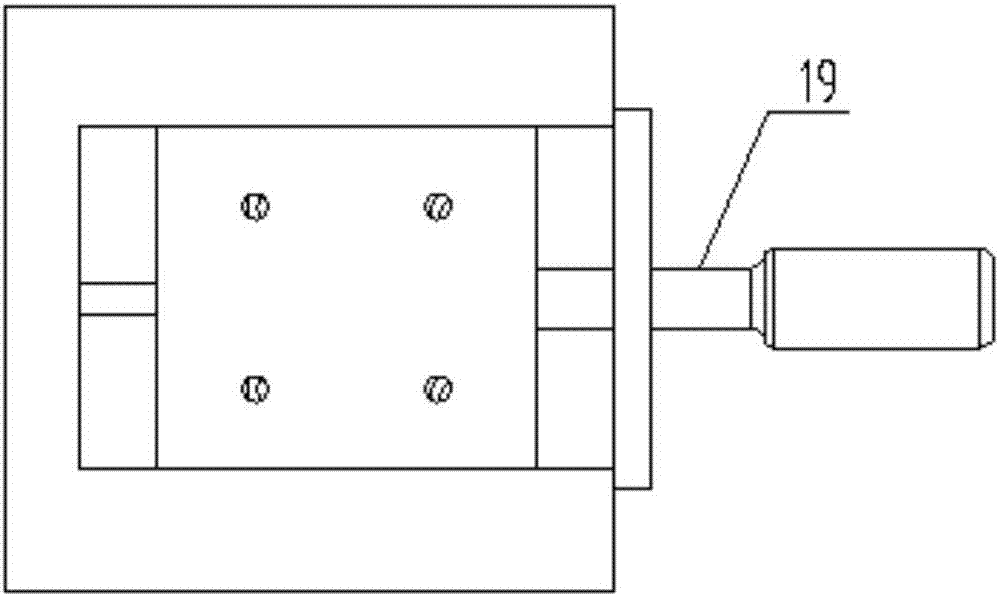

[0037] The surface of the above-mentioned self-collecting enhanced raceway is prepared by a cylindrical roller pressure coating device. The main structure of the cylindrical roller pressure coating device includes: a magnetic base 1, a connecting plate 2, a support column 3, and a compression screw 4 , support plate 5, translation platform 6, ti...

Embodiment 2

[0040] In this example, the preparation of the self-oil-collecting enhanced raceway surface is completed through the cylindrical roller pressure coating device described in Example 1. The specific process steps are as follows:

[0041] S1. If the inner surface of the ring to be coated is coated, the ring to be coated is fixed on a horizontal hollow shaft that can rotate at a constant speed, the magnetic base 1 is fixed on the outer sleeve of the hollow shaft, and the cylindrical roller 10 and the to-be The inner surfaces of the coated rings are in contact; if the outer surface of the ring to be coated is coated, the ring to be coated is fixed on a horizontal solid shaft that can rotate at a constant speed, and the magnetic base 1 is fixed on the outer sleeve of the solid shaft On, the cylindrical roller 10 is in contact with the outer surface of the ring to be coated;

[0042] S2, adjust the translation table 6 to adjust the width of the contact between the cylindrical roller ...

Embodiment 3

[0049] In this example, the performance of the self-collecting enhanced raceway surface is tested, and the base lubricating oil (PAO4) is used to measure the lubricated raceway width, the oil pool inlet distance and the film thickness under a fixed load condition, and then the pattern wettability is obtained. For the effect of self-collecting oil on the raceway, the specific experimental steps involved in self-collecting oil to enhance the surface of the raceway are as follows:

[0050] (1) Add 1 μl of lubricating oil to the lipophilic raceway in the middle of the self-collecting raceway, use a 25.4mm steel ball and a 150mm glass disc, and light sources with wavelengths of 655nm and 532nm to irradiate between the glass disc and the steel ball to form Interference fringes, keep the load constant, change the speed u to conduct experiments, measure the width of the oil pool, the distance from the entrance of the oil pool and the thickness of the central oil film;

[0051] (2) Dra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com