A Construction Method for Excavating Vertical Shafts by Ordinary Method in Very Thick Bedrock Aquifer

A construction method and common law technology, applied in the field of coal mine construction, can solve the problems of large water damage, long construction period and high cost, and achieve the effects of wellbore quality assurance, reduction of engineering and management costs, and shortening of construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

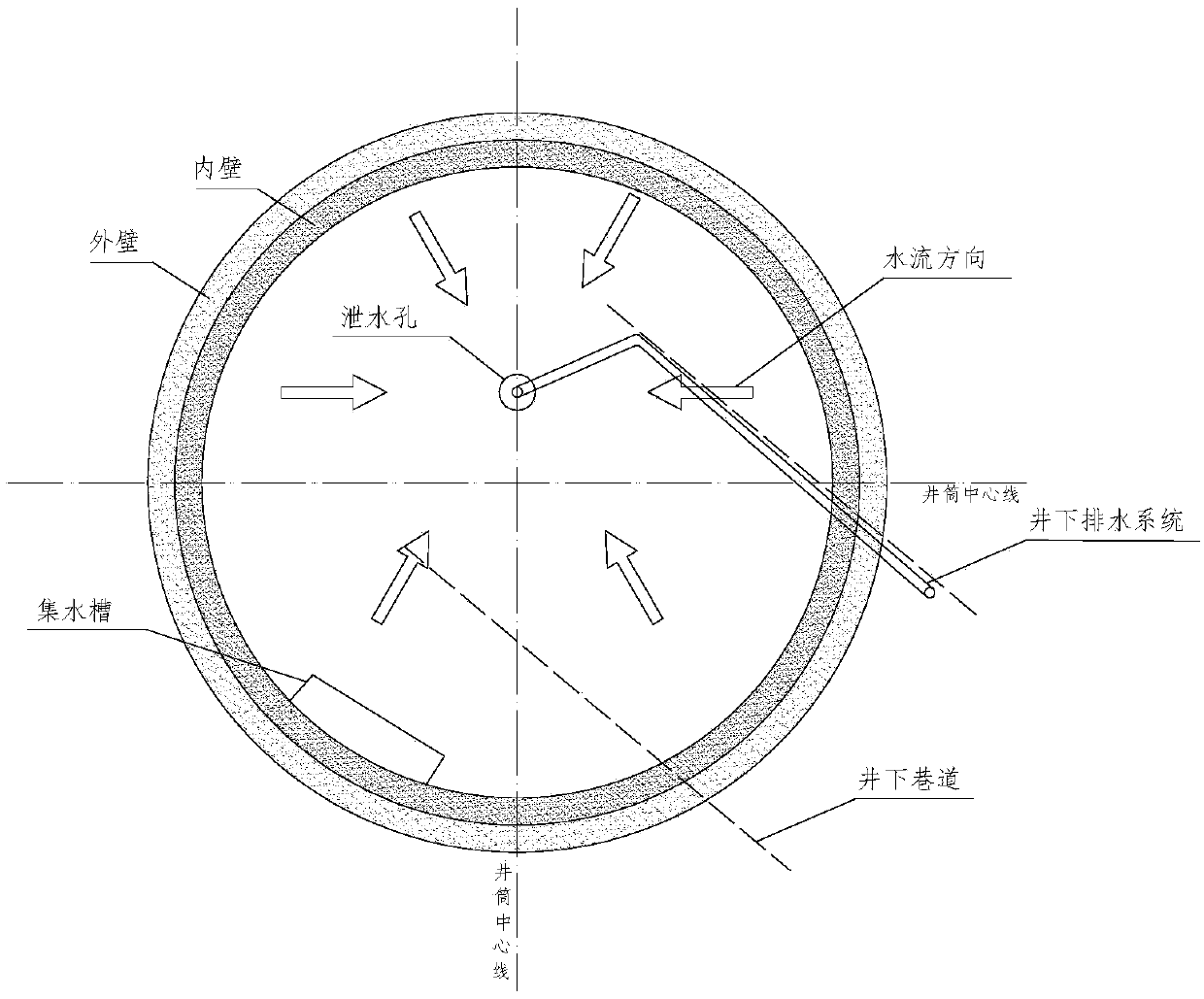

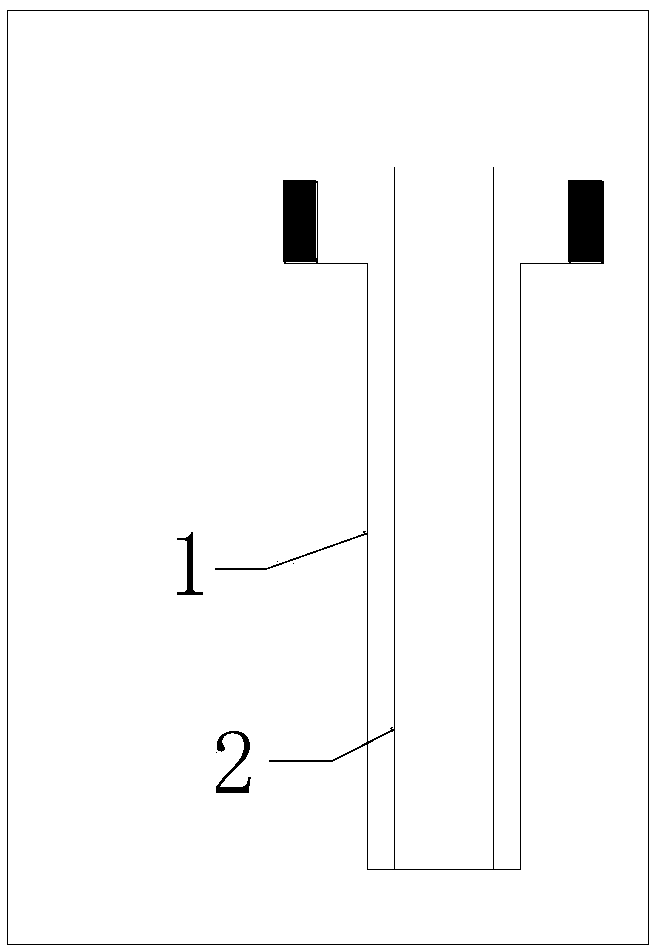

[0035] In this embodiment, a large-diameter drain hole 1 is pre-constructed before the wellbore is excavated, and a screen pipe 2 with a suitable diameter is inserted into the drain hole 1 to guide the groundwater in the aquifer to enter the underground drainage system through the borehole for drainage, so that the wellbore excavation position Above the water surface of the aquifer, it creates conditions for common law construction.

[0036] The construction method of the common method of digging shafts in the thick bedrock aquifer specifically includes the following steps:

[0037] (1) Construction of special drainage holes 1 within the scope of the shaft;

[0038] (2) Install the screen pipe 2 inside the drain hole to protect the wall, and improve the underground drainage system at the same time;

[0039] (3) Excavation and masonry mechanized operation lines such as drilling and blasting, rock grabbing and gangue removal, and wall building;

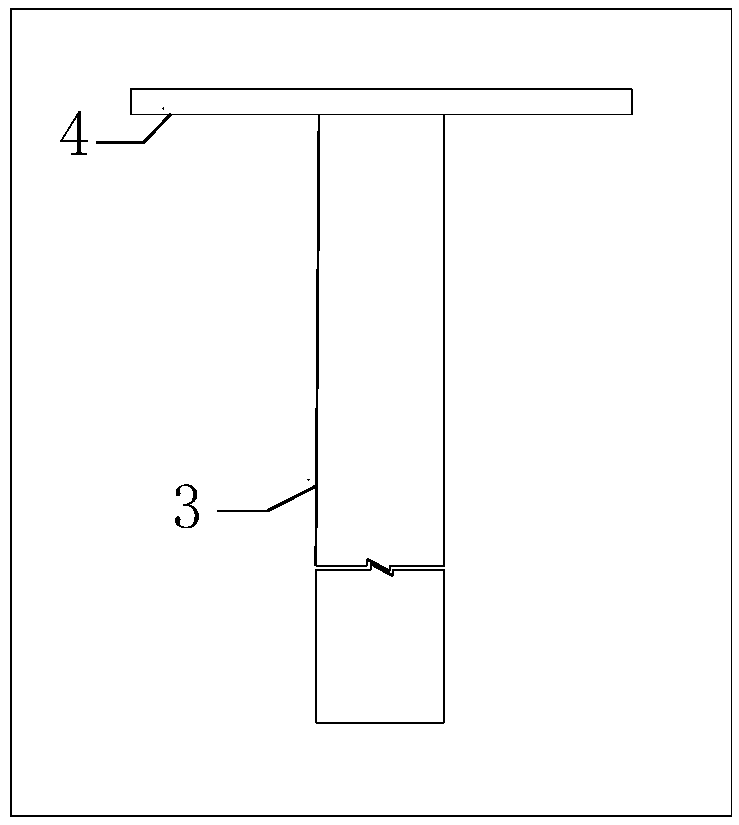

[0040] (4) Excavate the scuppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com