Micro-crack grouting plugging material and grouting technology in underground mine

A micro-crack and grouting technology, applied in sealing/isolation, wellbore/well components, earth-moving drilling, etc., can solve the problems of high price of chemical grouting materials, large particle size of ordinary cement and low viscosity, etc. Achieve the effect of increasing compactness, solving water damage problems and reducing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

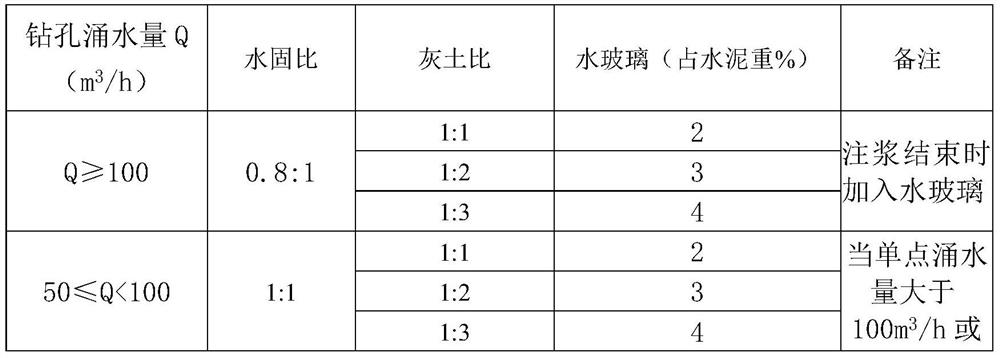

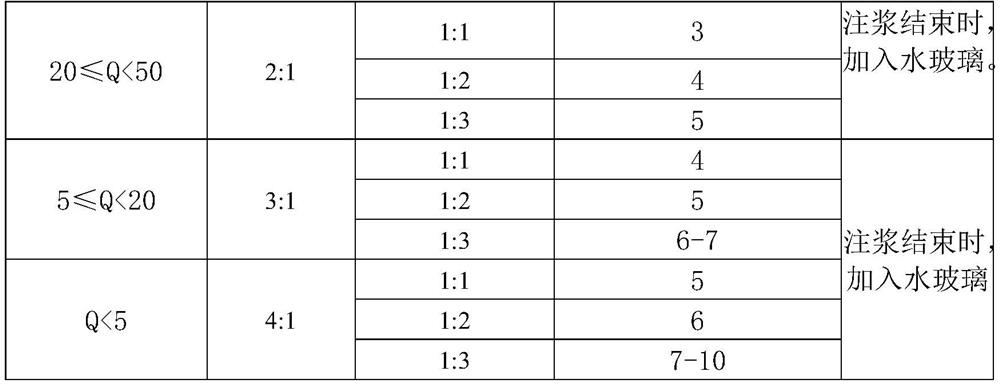

[0056] The grouting plugging material for micro-cracks in mine wells of the present invention comprises bentonite, superfine cement, water glass and water, and the bentonite is sodium-based bentonite, wherein the quality of water is equal to that of bentonite and superfine cement. The water-solid ratio of the mixture is 0.8:1-4:1, the mass lime-soil ratio of ultra-fine cement to bentonite is 1:1-1:3, and the amount of water glass added is 2%-10% of the ultra-fine cement.

[0057] In the present invention, the water content of bentonite is 5.9%.

[0058] In the present invention, the particle size of the solid particles in bentonite is not greater than 0.25mm, wherein the particle size of 0.25-0.075mm accounts for 2%, the particle size of 0.075-0.005mm accounts for 30.1%, and the particle size of 0.005-0.002mm The proportion of particle size is 12.7%, and the proportion of particle size less than 0.002mm is 55.2%.

[0059] from figure 1 It can be seen that the grouting and gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com