A water-rock combined grouting filling stope control method for water control

A stope and grouting technology, applied in drainage, filling, mining equipment, etc., can solve problems such as surface subsidence, water resource waste, water damage, etc., and achieve the effects of reducing hazards, saving water resources, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

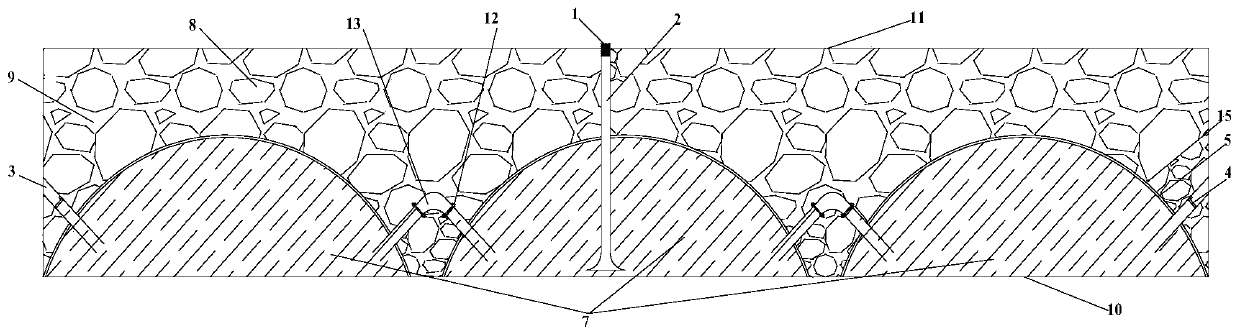

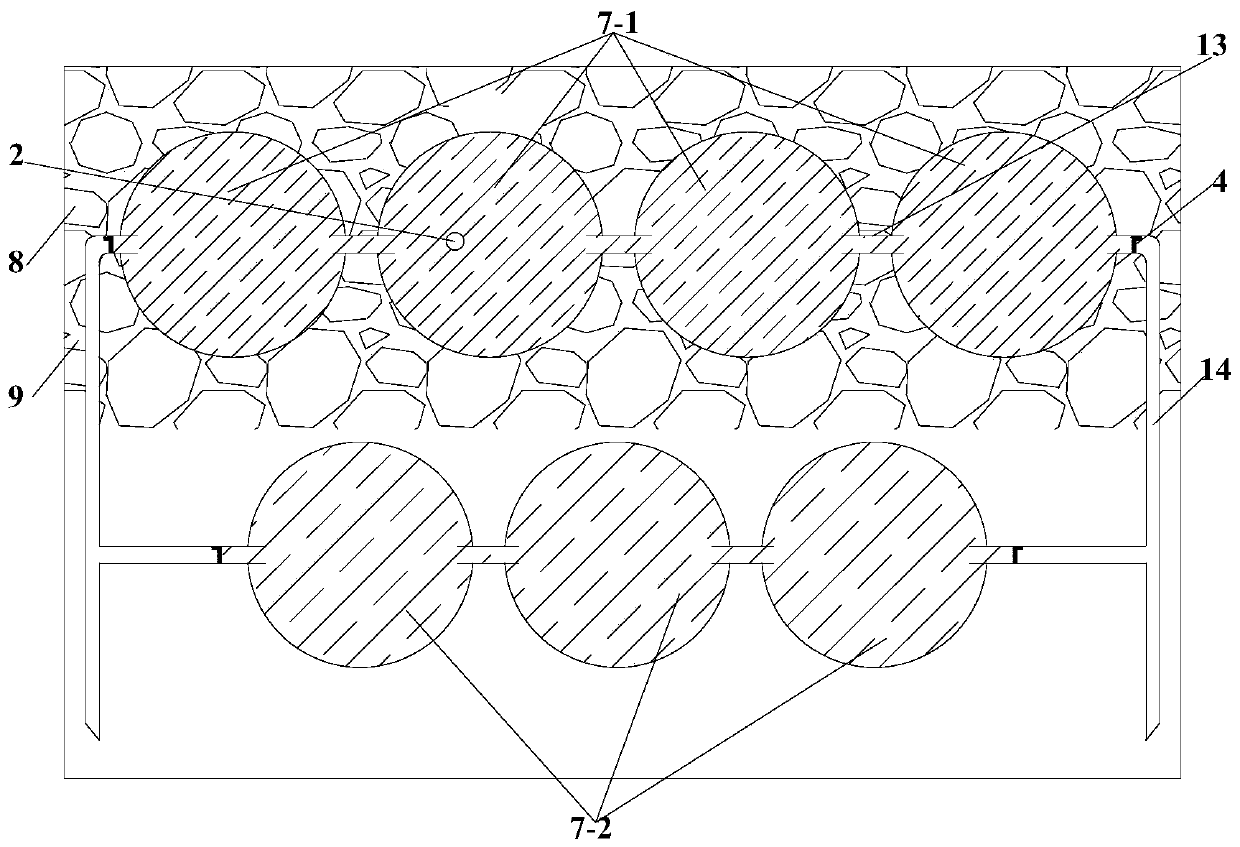

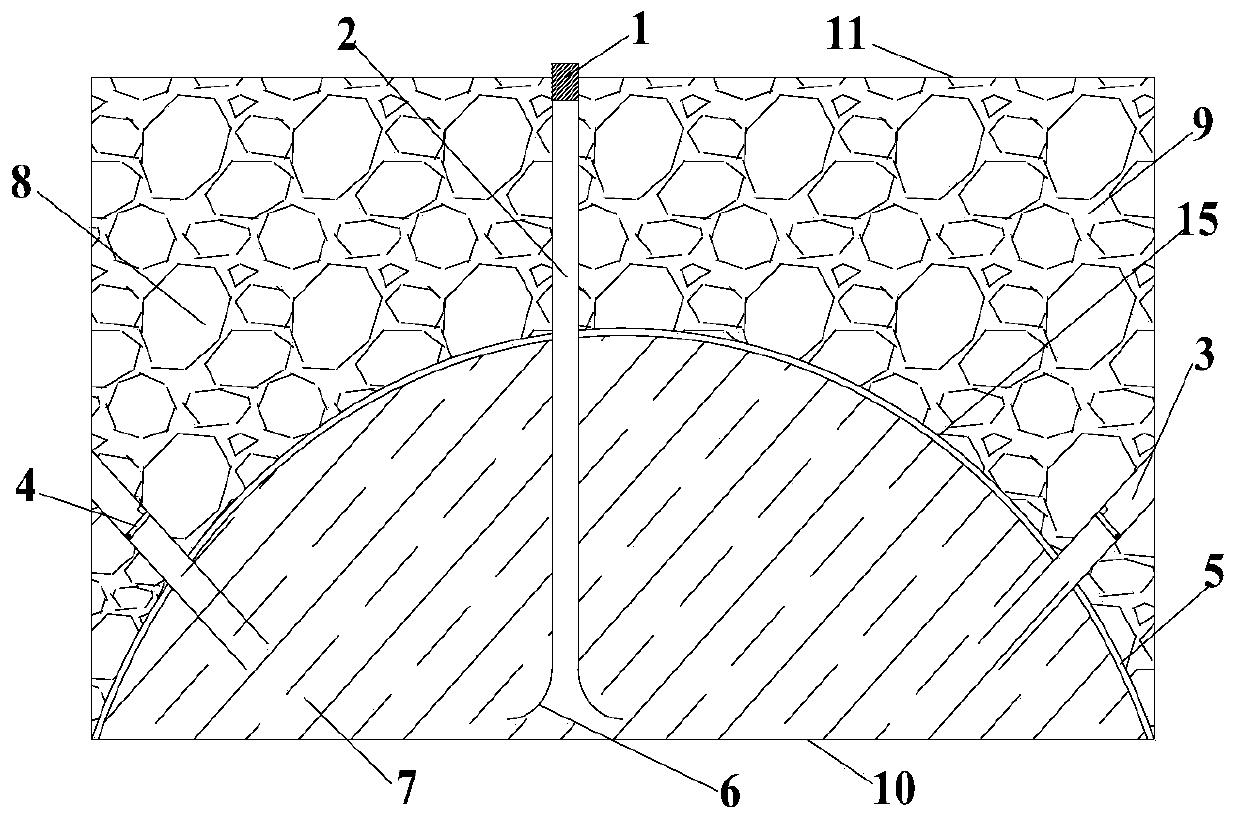

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0039] A water-rock combined grouting filling stope water control method of the present invention comprises the following steps:

[0040] Step 1: measure the water content in the engineering area in the early stage of mining, and estimate the parameters of the stope; and calculate the estimated total drainage in the stope according to the water content of the mine, and design a single temporary water tank 7 and its volume and level group number , to ensure that the temporary water tank 7 is in a fully expanded state after the water is pressurized and pumped into the stagnant water;

[0041] Step 2: Fix the lower surface of the temporary water tank to the bottom plate with a diaphragm 10 and ensure full contact with the bottom plate. A layer of thin diaphragm 15 is also laid on the outside of the inner surface layer 5. At the same time, the inner surface layer 5 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com