Preparation method of quick in-situ construction of apatite nanorod with certain orientation on surface of titanium micro-arc anti-oxidization coating layer

A technology of micro-arc oxidation and apatite, which is applied in the direction of coating, nanotechnology, surface reaction electrolytic coating, etc., can solve the problems of large loss of elements, no orientation, disorder, etc., to achieve extended application and improve binding ability , reducing the effect of elapsed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

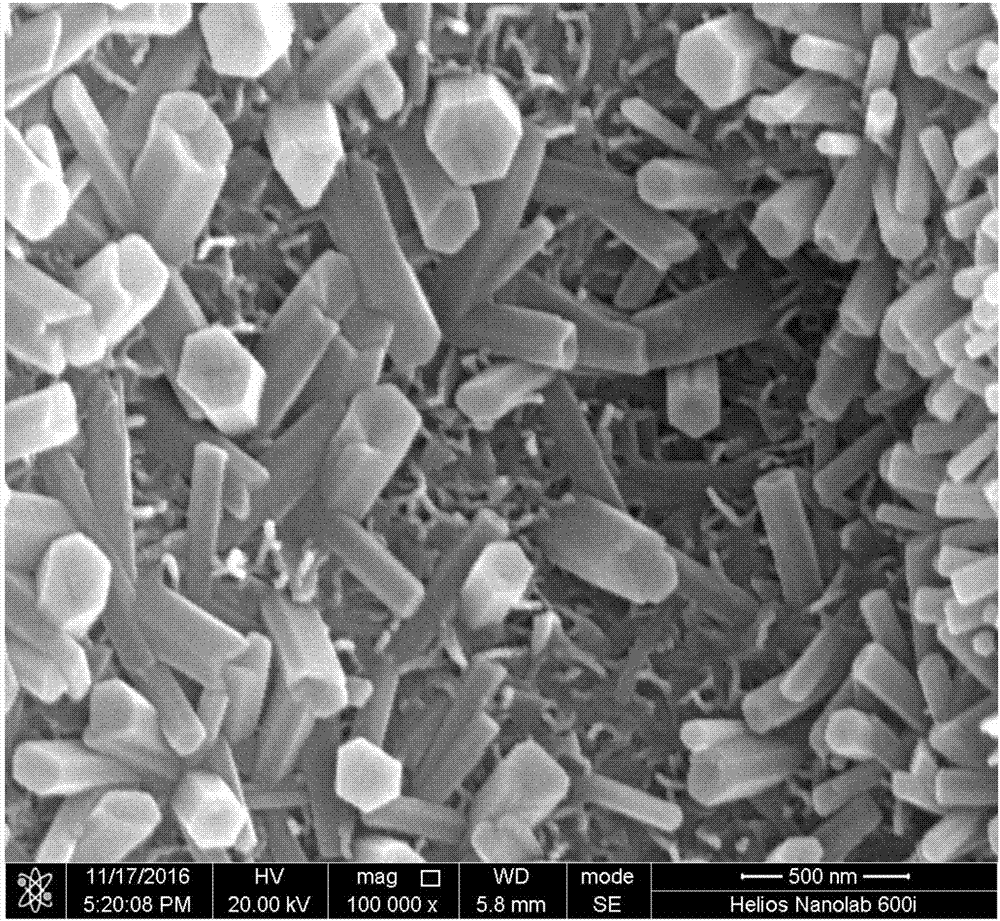

[0021] Specific Embodiment 1: A method for rapidly in situ constructing apatite nanorods with a certain orientation on the surface of titanium micro-arc oxidation coating described in this embodiment is specifically carried out according to the following steps:

[0022] 1. Pretreatment of titanium materials: After grinding and polishing the surface of titanium materials with 200#, 400# and 1000# metallographic sandpaper in sequence, wash them with deionized water and dry them at a temperature of 20°C to 80°C 0.5h~5h, get the titanium material after pretreatment;

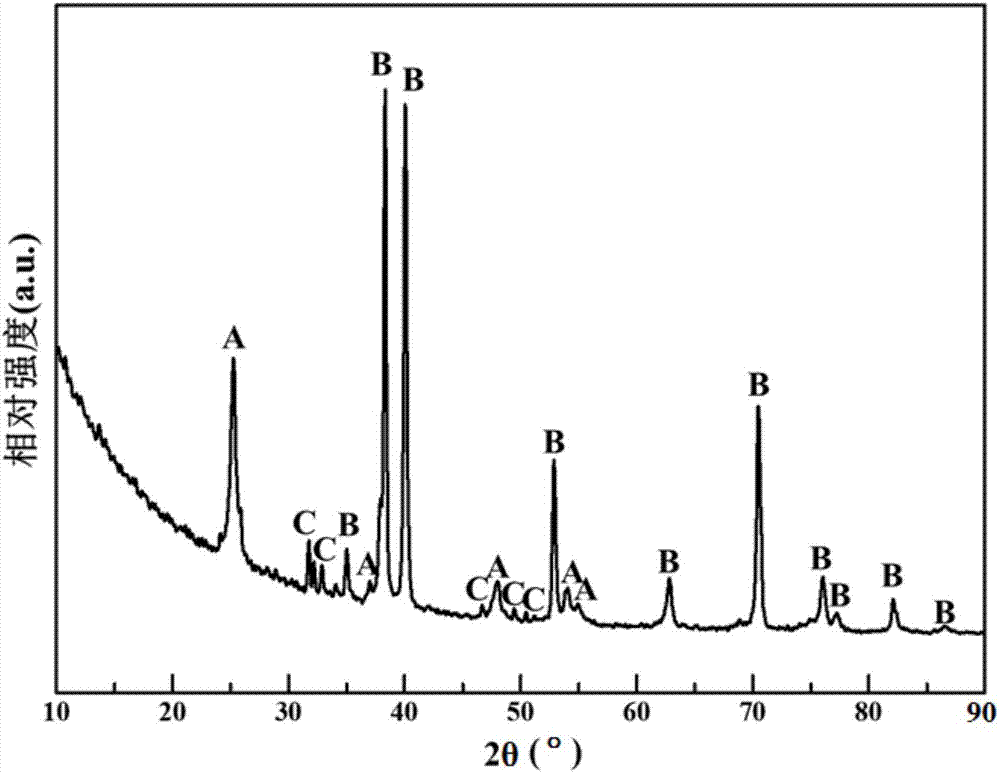

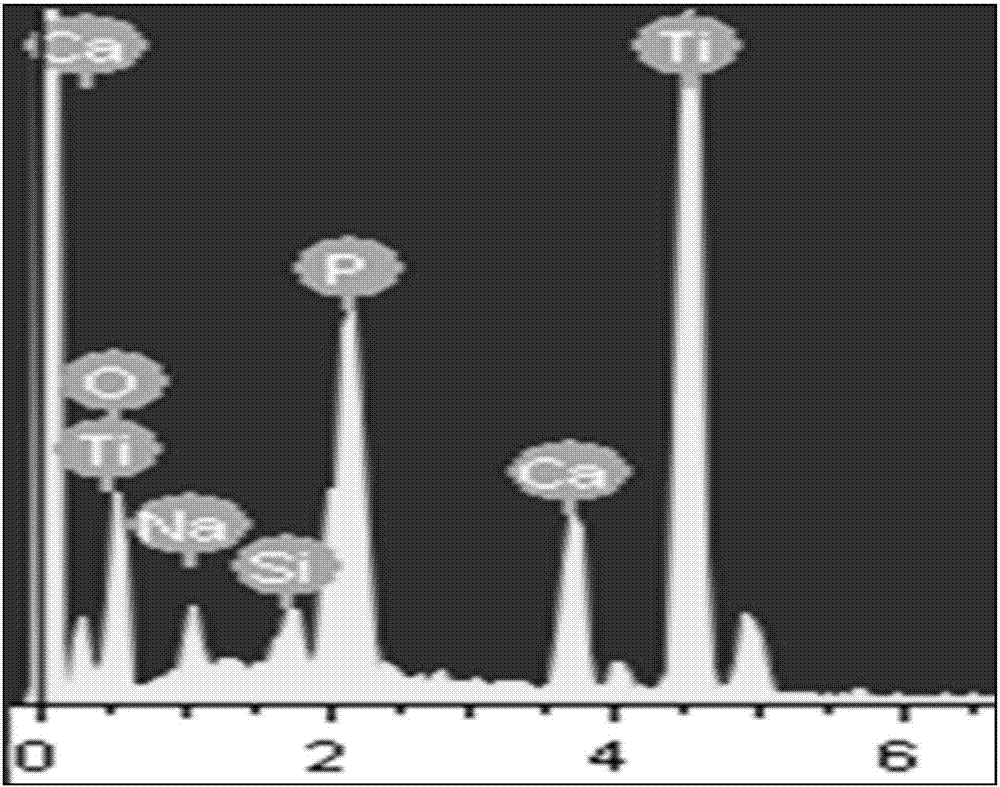

[0023] 2. Micro-arc oxidation treatment: place the pretreated titanium material in a stainless steel electrolytic cell containing the electrolyte of biologically active components, use the pretreated titanium material as the anode, and the stainless steel plate as the cathode for micro-arc oxidation. DC voltage, under the conditions of voltage 200V-500V, pulse frequency 200Hz-1000Hz, duty cycle 4%-30%, and electrolyt...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment is different from Embodiment 1 in that the titanium material described in step 1 is titanium or titanium alloy. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the titanium material is TA2, TA3, TA4, TC4 or Ti2448. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com