Composite microwave absorbing material prepared through three steps of reaction and preparation method

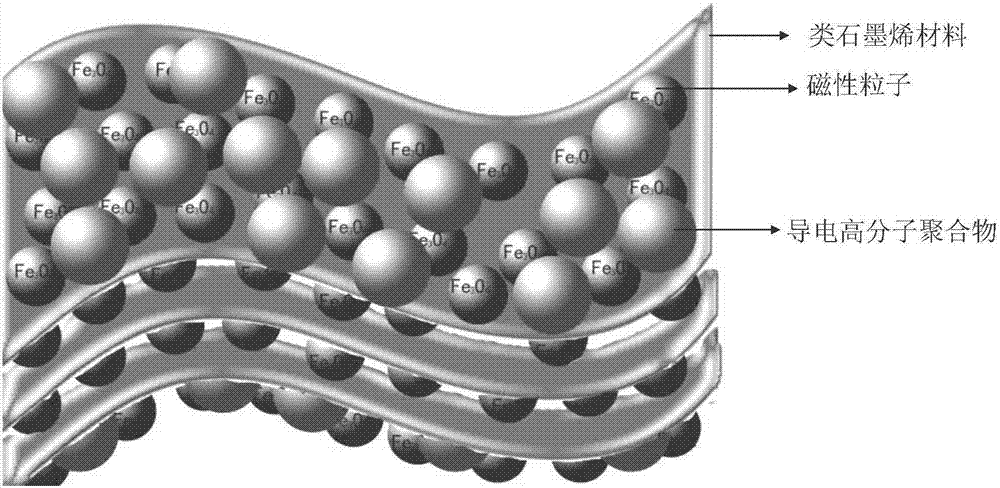

A composite absorbing material and reaction technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, other chemical processes, etc., can solve the problems of limited industrial utilization of materials, poor electromagnetic wave reflection loss, and different electromagnetic wave absorption frequency bands. Width and other issues, to achieve great practical application value, improve the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

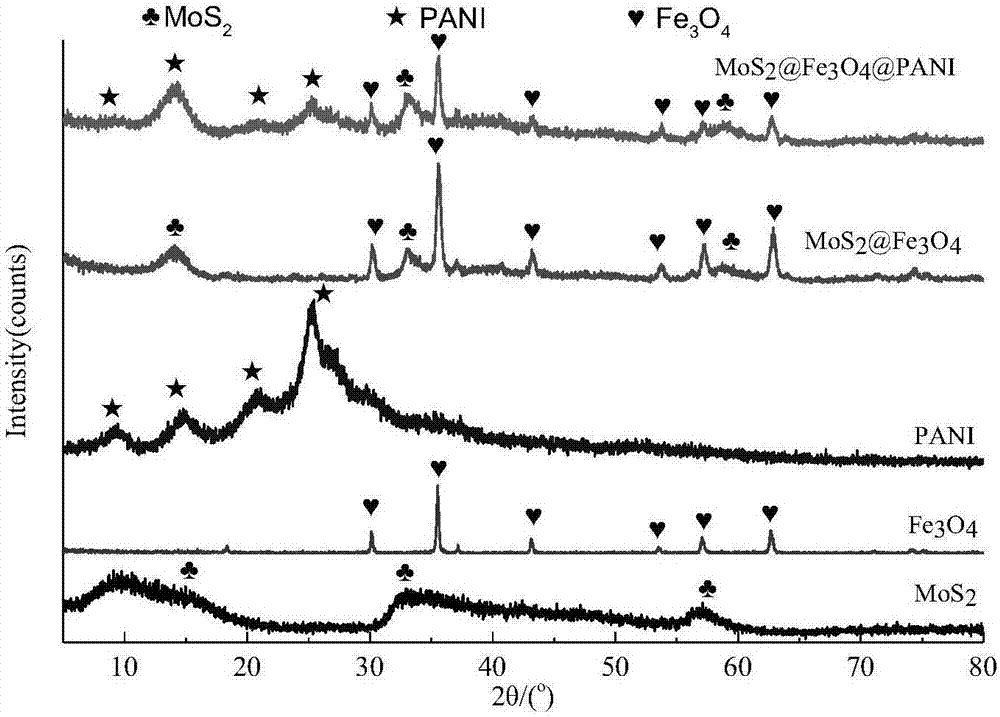

[0033] 1. Molybdenum disulfide (MoS 2 ) preparation;

[0034] Weigh 12g of thioacetamide and 9.68g of sodium molybdate and dissolve them in water, transfer them to a hydrothermal kettle, put them in an oven preheated to 200-245°C for 3-10 hours, then stop heating and naturally cool to room temperature. Open a kettle, wash, and freeze-dry to obtain a black solid powder.

[0035] 2.MoS 2 @Fe 3 o 4 preparation of

[0036] ① Pre-preparing a mixed solution of ethanol and deionized water, adding 0.5-1 g of the molybdenum disulfide powder prepared above to it, and stirring it ultrasonically.

[0037] ② Accurately weigh 0.02mol ferric chloride (anhydrous) and 0.01mol ferric chloride and dissolve them in deionized water.

[0038] ③Mix the above two solutions and stir in an oil bath less than 100°C for 30 minutes;

[0039] ④ Transfer the above solution to a hydrothermal reaction kettle, then quickly inject 2.5-3ml of concentrated ammonia water, seal the kettle, put it in an oven ...

Embodiment 1

[0043] Molybdenum disulfide (MoS 2 ) preparation;

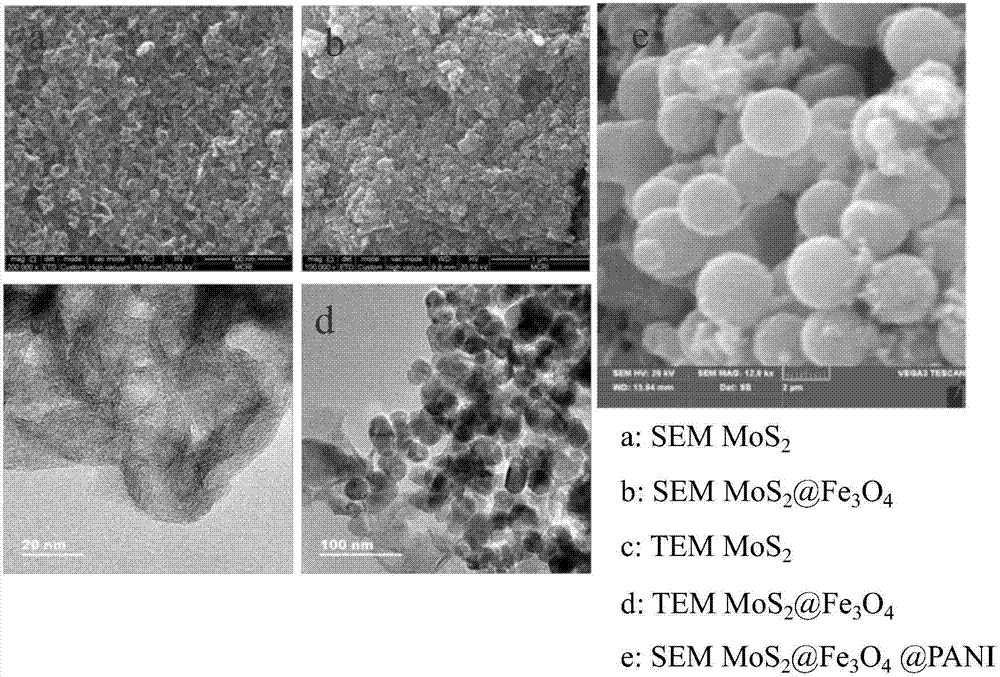

[0044] Weigh 1.2g of thioacetamide, dissolve 0.9g of sodium molybdate in 60ml of deionized water, stir ultrasonically for 30min, transfer to a polystyrene-lined hydrothermal kettle, and put it in an oven preheated to 240°C for reaction 7 Hours, then stop heating and cool to room temperature naturally, open the kettle, wash, and freeze-dry to obtain a black solid powder.

Embodiment 2

[0046] MoS 2 @Fe 3 o 4 preparation of

[0047] ① Prepare a mixed solution of 30ml of ethanol and 30ml of deionized water, add 0.2g of molybdenum disulfide powder prepared above, and stir it ultrasonically for 30min.

[0048] ② Accurately weigh 0.35g of ferric chloride and 0.214g of ferric chloride and dissolve in 10ml of deionized water.

[0049] ③Mix the above two solutions and stir in an oil bath at 80°C for 30 minutes;

[0050] ④ Transfer the above solution to a hydrothermal reaction kettle, then quickly inject 3ml of 26% ammonia water, seal the kettle, put it in an oven at 110°C for 3 hours, cool it down to room temperature naturally, open the kettle, wash several times, and dry at 60°C Molybdenum disulfide supported by ferric oxide is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com