A silicon carbide nanowire reinforced c/c-sic-zrb 2 Preparation method of ceramic matrix composite material

A silicon carbide nanowire, c-sic-zrb2 technology, applied in the field of materials, achieves good preservation, improved mechanical properties, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

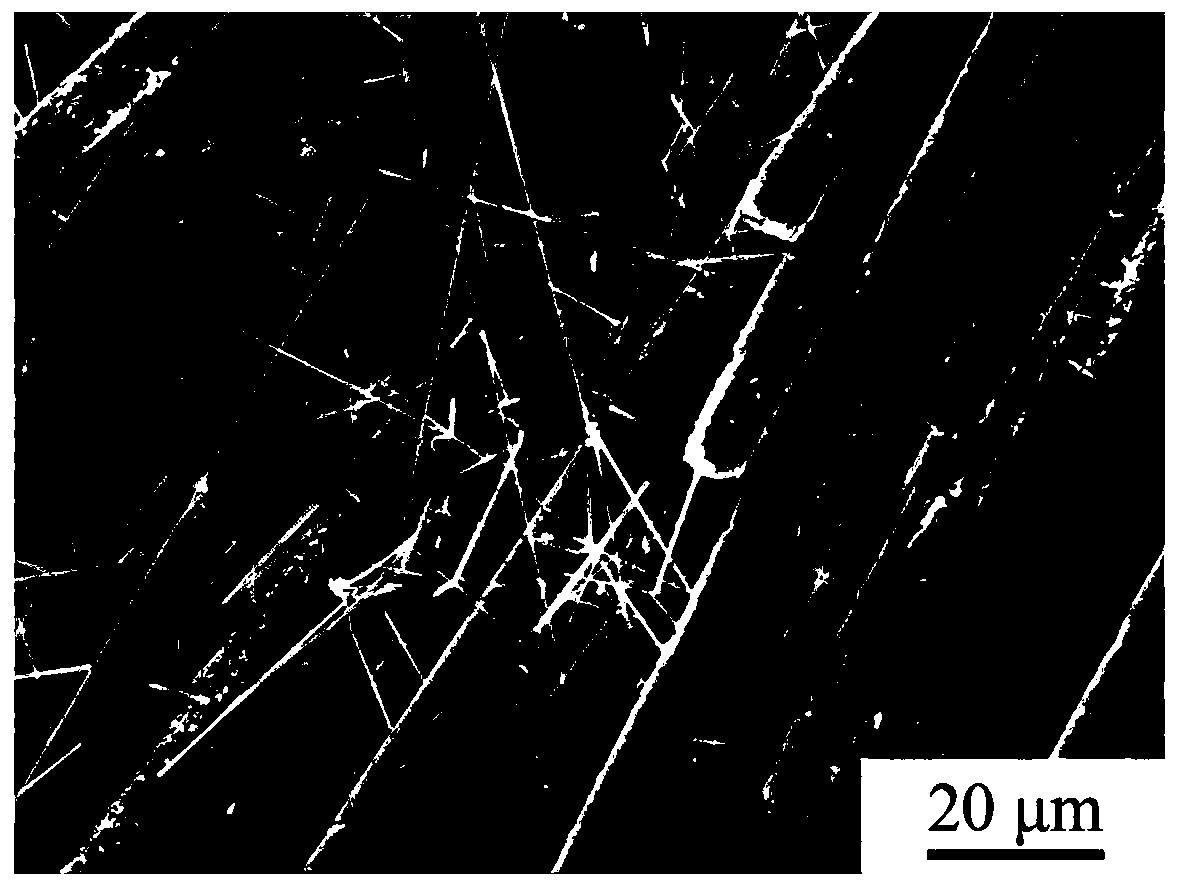

Image

Examples

Embodiment 1

[0032] Step 1: Put the carbon fiber preform into anhydrous ethanol for ultrasonic cleaning for 20 minutes, and dry the cleaned carbon fiber preform for 10 hours at a temperature of 100°C for use;

[0033]Step 2: Preparation of porous C / C preform, placing the carbon fiber preform in an isothermal chemical vapor deposition furnace, using natural gas as a precursor, and depositing pyrolytic carbon to protect the carbon fiber preform at 1100 ° C, the natural gas flow rate is 80ml / min, The deposition time is 5h; after the deposition is completed, it is cooled in the furnace to obtain a porous C / C preform;

[0034] Step 3: Stir the absolute ethanol and ethyl orthosilicate solution evenly, then add a small amount of distilled water, ferrocene and hydrochloric acid, and stir again to make a silica sol; the absolute ethanol, ethyl orthosilicate, The molar ratio of distilled water, ferrocene and hydrochloric acid is 3:1:5:0.01:0.2;

[0035] Step 4: Immerse the porous C / C preform in the...

Embodiment 2

[0040] Step 1: Put the carbon fiber preform into anhydrous ethanol for ultrasonic cleaning for 20 minutes, and dry the cleaned carbon fiber preform for 10 hours at a temperature of 100°C for use;

[0041] Step 2: Preparation of porous C / C preform, placing the carbon fiber preform in an isothermal chemical vapor deposition furnace, using natural gas as a precursor, and depositing pyrolytic carbon to protect the carbon fiber preform at 1100 ° C, the natural gas flow rate is 80ml / min, The deposition time is 5h; after the deposition is completed, it is cooled in the furnace to obtain a porous C / C preform;

[0042] Step 3: Stir the absolute ethanol and ethyl orthosilicate solution evenly, then add a small amount of distilled water, ferrocene and hydrochloric acid, and stir again to make a silica sol; the absolute ethanol, ethyl orthosilicate, The molar ratio of distilled water, ferrocene and hydrochloric acid is 3:1:5:0.01:0.2;

[0043] Step 4: Immerse the porous C / C preform in th...

Embodiment 3

[0048] Step 1: Put the carbon fiber preform into anhydrous ethanol for ultrasonic cleaning for 20 minutes, and dry the cleaned carbon fiber preform for 10 hours at a temperature of 100°C for use;

[0049] Step 2: Preparation of porous C / C preform, placing the carbon fiber preform in an isothermal chemical vapor deposition furnace, using natural gas as a precursor, and depositing pyrolytic carbon to protect the carbon fiber preform at 1100 ° C, the natural gas flow rate is 80ml / min, The deposition time is 5h; after the deposition is completed, it is cooled in the furnace to obtain a porous C / C preform;

[0050] Step 3: Stir the absolute ethanol and ethyl orthosilicate solution evenly, then add a small amount of distilled water, ferrocene and hydrochloric acid, and stir again to make a silica sol; the absolute ethanol, ethyl orthosilicate, The molar ratio of distilled water, ferrocene and hydrochloric acid is 3:1:5:0.01:0.2;

[0051] Step 4: Immerse the porous C / C preform in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com