Reinforced thermoplastic pipe end forming device and method

A technology of enhanced thermoplasticity and tube end forming, which is applied to tubular objects, other household appliances, household appliances, etc., can solve problems such as difficult interfaces, RTP service life, etc., and achieve good economic benefits, good molding effects, and simple overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

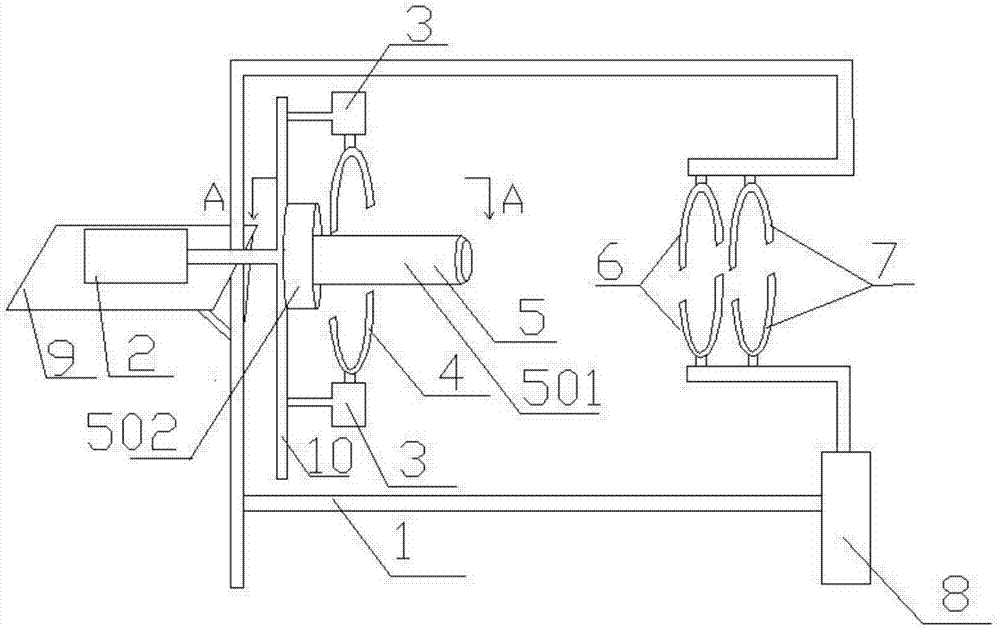

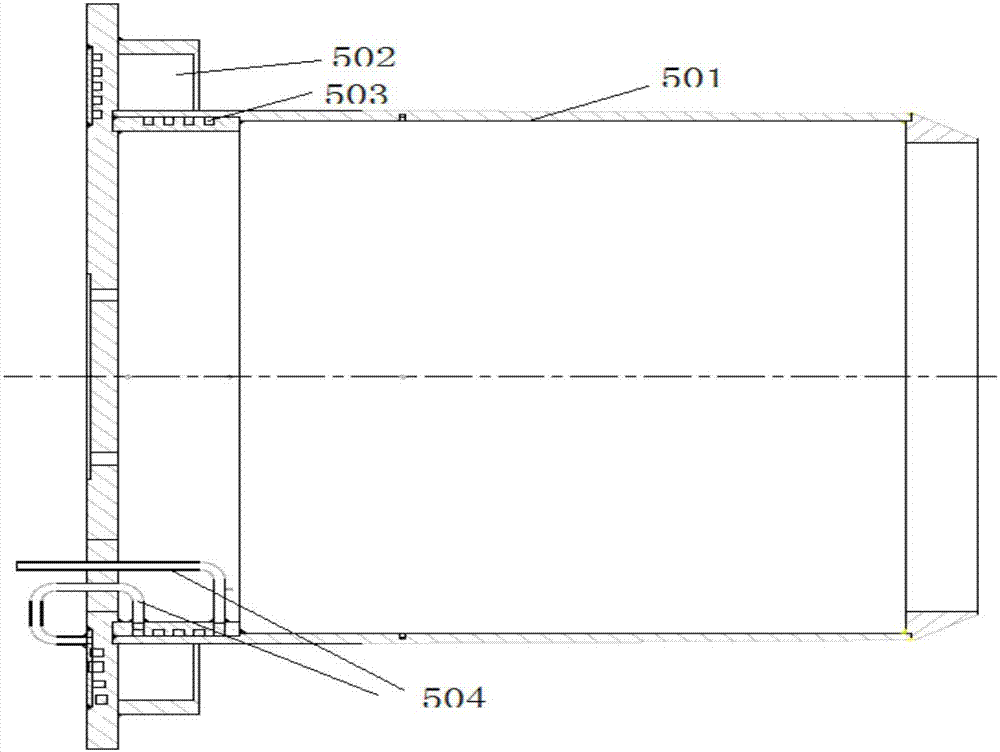

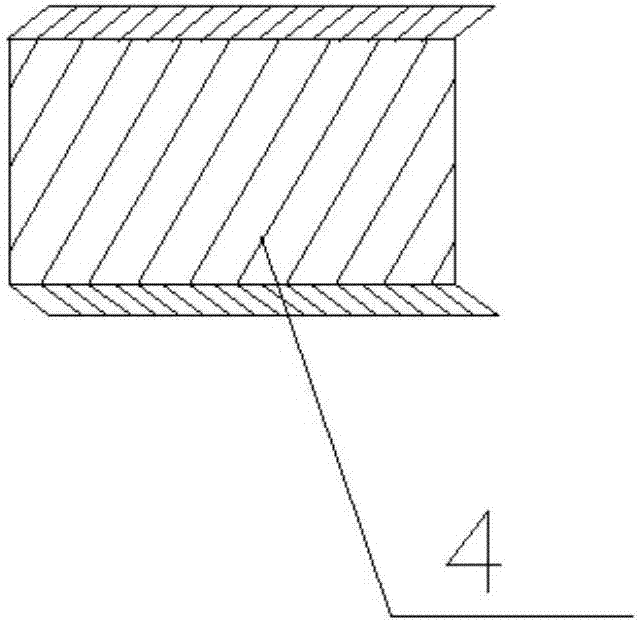

[0032]The main structure of the RTP pipe end forming device involved in this embodiment includes a first bracket 1, an oil cylinder 2, a forming cylinder 3, a movable forming block 4, a forming mold 5, a fixed forming block 6, a fixed clamp 7, a fixed clamping cylinder 8, Support plate 9 and the second support 10, the middle part of the first support 1 of the vertically arranged rectangular frame structure is provided with support plate 9 horizontally, is provided with oil cylinder 2 horizontally on support plate 9, and the end of oil cylinder 2 and the vertically arranged first The two brackets 10 are connected by bolts or riveting. The middle part of the second bracket 10 is horizontally provided with a molding die 5. The molding die 5 includes an inner mold 501, an outer mold 502, an oil passage 503 and an oil pipe 504. The inner mold 501 of the core structure is horizontally fitted with an annular outer mold 502, there is an annular gap between the outer mold 502 and the in...

Embodiment 2

[0040] The difference between this embodiment and embodiment 1 is: the RTP pipe end forming method,

[0041] (1) Start the forming cylinder 3: first start the forming cylinder 3, the forming cylinder 3 drives the movable forming block 4 to move vertically up and down, and the movable forming block 4 is clamped on the forming mold 5;

[0042] (2) Fix the RTP tube: then place the pipe end of the RTP tube to be sealed on the fixed forming block 6 and the fixed fixture 7, start the fixed clamping cylinder 8, and the fixed clamping cylinder 8 drives the lower semicircle of the fixing fixture 7 to be vertical Move upwards so that the RTP tube to be sealed is clamped and fixed;

[0043] (3) Forming: Then start the oil cylinder 2, and the oil cylinder 2 pushes the forming mold 5 forward, so that the end of the RTP pipe is close to the movable forming block 4, and the heat conduction oil is passed, and the temperature of the heat conduction oil is set to 180°C, and the electric heating...

Embodiment 3

[0047] The difference between this example and Example 2 and Example 3 is: the temperature of the heat transfer oil in step (3) is 200°C, and the heating temperature of the electric heating plate is set to 200°C; step (4) is to stop heating after 1.5 hours ; Step (5) is after cooling for 45 minutes, the oil cylinder 2 retreats.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Nominal outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com