Method for preparing fermented soybeans in water

A production method and technology of fermented soya bean, which is applied in the direction of antimicrobial preservation of food components, food science, food preservation, etc., can solve problems such as rancidity of fermented soya bean, and achieve the effects of avoiding rancidity, shortening production time, and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

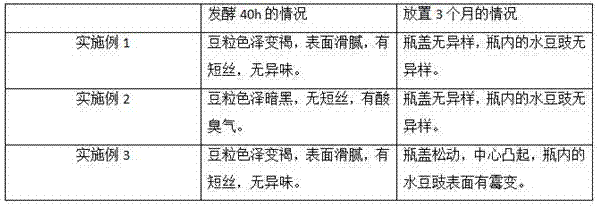

Embodiment 1

[0024] The application provides a method for preparing fermented soya beans, comprising the following steps:

[0025] Step 1. Raw material processing: take 1500g of soybeans, soak them in warm water at 25°C for 3.5 hours, then take out the soybeans, and steam them under a pressure of 0.15Mpa for 12 minutes to obtain steamed soybeans;

[0026] Step 2. Cultivation of tempeh koji: When the cooked beans are naturally cooled to 45~50°C, wrap the soybeans with a cloth, put them into a cardboard box filled with space cotton, and cover the top with a cotton pillow to keep warm. Place at 26°C for 25 hours, remove the cotton pillow, and continue to stand for 36 hours to obtain Douchi Koji;

[0027] Step 3. Fermentation: Add 400g of salt, 350g of ginger rice and 10g of Zanthoxylum bungeanum to the tempeh koji, put them together into a fermenter that has been cleaned and steam sterilized, then add 3700ml of cold boiled water, stir evenly, cover and ferment. The room temperature is contro...

Embodiment 2

[0032] The difference between this embodiment and embodiment 1 is that during the fermentation period, the fermented soya bean is not stirred regularly.

Embodiment 3

[0034] The difference between this embodiment and Embodiment 1 is that no lemon slices are added to adjust the pH value of the tempeh water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com