Camphor tree seedling raising method

A camphor tree and seedling refining technology, applied in the field of camphor tree seedling raising, can solve problems such as underdeveloped root system, difficult large-scale production demand, waste of branches and the like, and achieve the effect of high nutrient content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

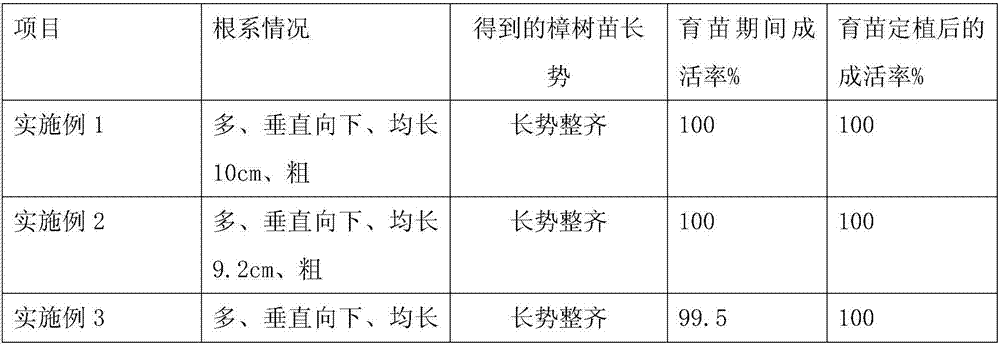

Examples

Embodiment 1

[0041] 1. Raw material preparation:

[0042] 1. Slow-release fertilizer granules are made of the following raw materials in parts by weight: 1 part of trace elements, 1 part of urea, 1 part of ammonium dihydrogen phosphate, 0.5 parts of crab shells, 0.5 parts of pig testicles, 1.5 parts of molasses, 0.5 parts of coconut bark, 0.5 parts of banyan dead branches, 0.5 parts of lotus stems, 0.5 parts of pennisetum, 0.5 parts of tall fescue, 0.5 parts of bermudagrass and 1.5 parts of cellulase

[0043] 2.5 parts of thiourea, 2.5 parts of phenylphosphoramide, 2 parts of propylene glycol alginate, 3 parts of cyanide;

[0044] Among them, trace elements include 1 part of boron fertilizer, 0.5 part of cobalt fertilizer, 1 part of zinc fertilizer, 1 part of copper fertilizer, 0.5 part of molybdenum fertilizer, 0.5 part of manganese fertilizer, and 0.5 part of iron fertilizer;

[0045] Apply the raw materials of the above ratio to the following method for preparing slow-release fertilize...

Embodiment 2

[0066] 1. Raw material preparation:

[0067] 1. Slow-release fertilizer granules are made of the following raw materials in parts by weight: 5 parts of trace elements, 4 parts of urea, 3 parts of ammonium dihydrogen phosphate, 2 parts of crab shells, 2 parts of pig testicles, 0.5 parts of molasses, 1 part of coconut bark, 1 part of dead branch of banyan tree, 2 parts of lotus stem, 1 part of pennisetum, 1 part of tall fescue, 1 part of bermudagrass and 1.5 parts of cellulase

[0068] 5 parts of thiourea, 5 parts of phenylphosphoramide, 2 parts of propylene glycol alginate, 2 parts of cyanoacrylate-acetylated hydroxypropyl cellulose, 2 parts of furan resin and 2 parts of polyurethane;

[0069] Among them, trace elements include 2 parts of boron fertilizer, 3 parts of cobalt fertilizer, 3 parts of zinc fertilizer, 3 parts of copper fertilizer, 3 parts of molybdenum fertilizer, 3 parts of manganese fertilizer and 3 parts of iron fertilizer;

[0070] Apply the raw materials of th...

Embodiment 3

[0091] 1. Raw material preparation:

[0092] 1. Slow-release fertilizer granules are made of the following raw materials in parts by weight: 3 parts of trace elements, 2 parts of urea, 2 parts of ammonium dihydrogen phosphate, 1.5 parts of crab shells, 1.5 parts of pig testicles, 1 part of molasses, 1 part of coconut bark, 1.5 parts of dead branches of banyan tree, 1 part of lotus stem, 1.5 parts of pennisetum, 1 part of tall fescue, 1 part of bermudagrass and 1.5 parts of cellulase

[0093] 4 parts of thiourea, 5 parts of phenylphosphoramide, 2 parts of cyanoacrylate-acetylated hydroxypropyl cellulose, 2 parts of furan resin and 2 parts of polyurethane;

[0094] Among them, trace elements include 0.5 part of boron fertilizer, 1 part of cobalt fertilizer, 0.5 part of zinc fertilizer, 0.5 part of copper fertilizer, 0.5 part of molybdenum fertilizer, 1 part of manganese fertilizer and 1 part of iron fertilizer;

[0095] Apply the raw materials of the above ratio to the followin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com