Machine-blast combined mining device for fully-mechanized coal mining working face

A working face and joint mining technology, which is applied in the field of fully mechanized rock mining machinery and drilling trucks, can solve the problems of not being able to meet the requirements of combined mining of mine machines and guns, susceptible to uneven force, and affecting stability, etc., and achieves compact structure, The effect of balanced force and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

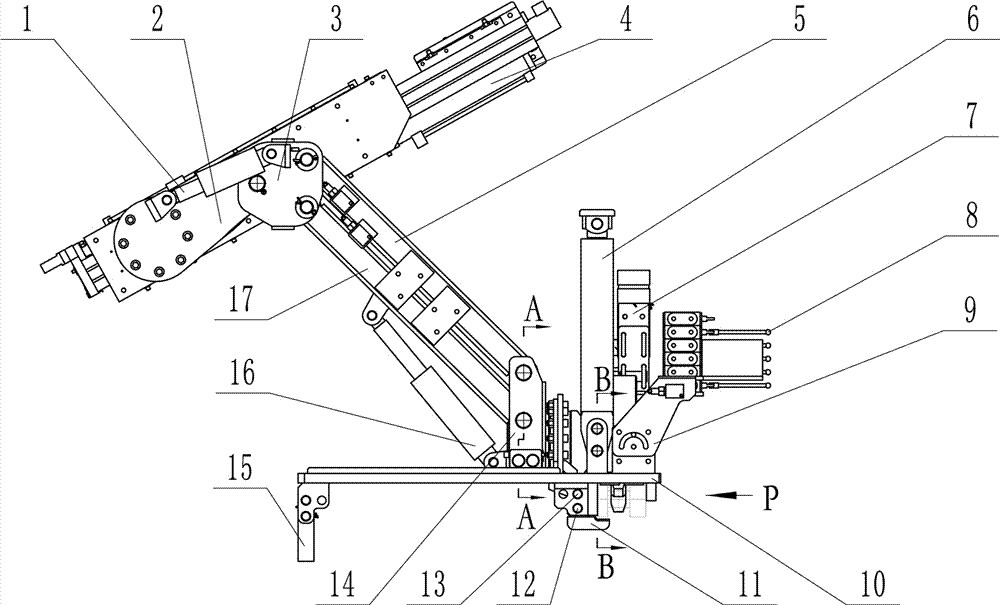

[0033] according to Figure 1-11 The specific structure of the present invention will be described in detail. The fully mechanized mining operation face machine gun combined mining device includes a support platform 10, a rock drilling device 4 supported by a linkage adjustment mechanism assembled on the support platform 10, a hydraulic prop 6 hinged with the support platform 10, and a support platform 10 fixed on the Parts such as band brake motor 19 and hydraulic control device 8. One side of the support platform 10 is assembled on the side of the scraper conveyor (not shown in the figure) through the U-shaped support shoe 15 , and the other side is clamped on the pin rail 18 of the scraper conveyor through the rotating slide card 11 . The road wheel 20 driven by the motor with brake 19 is engaged with the pin rail 18, and the road wheel 20 walks on the pin rail 18, driving the support platform 10 to move along the length direction of the pin rail 18 and the groove side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com