Intercalated hydrotalcite anti-ultraviolet aging agent for rubber as well as preparation method and usage method thereof

An anti-ultraviolet aging agent, hydrotalcite technology, applied in the field of inorganic functional materials, can solve the problems of economic loss, accelerated aging, environmental pollution, etc., and achieve the effect of reducing hysteresis loss and heat generation, enhancing reinforcement effect, and improving interaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

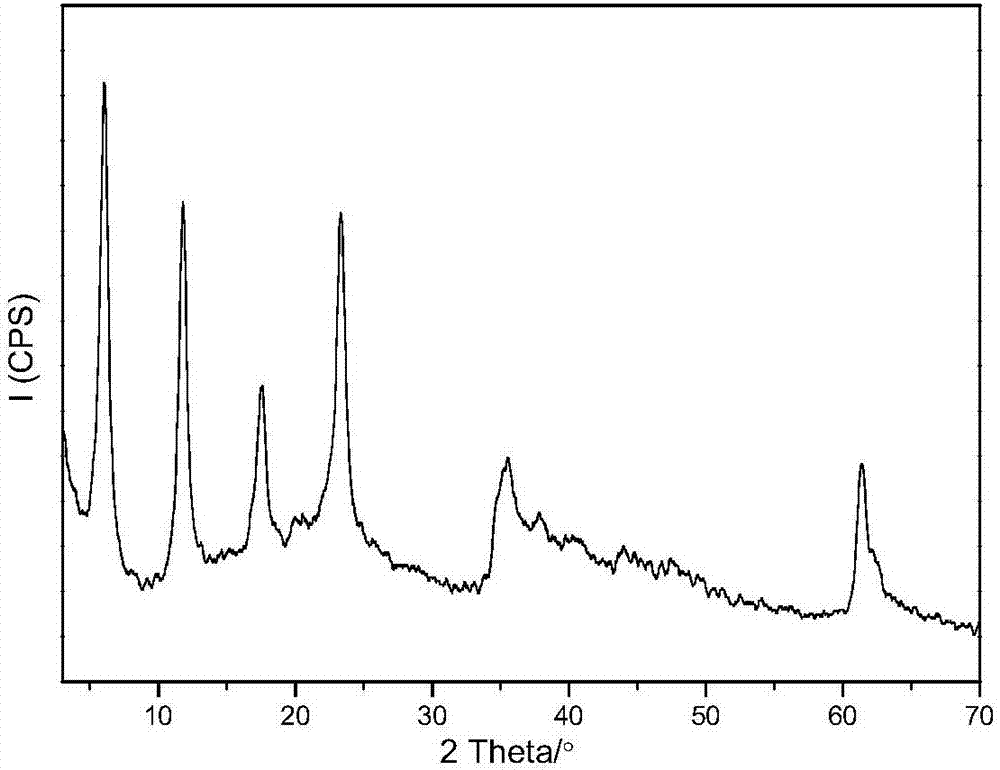

Embodiment 1

[0022] Step A: 30.77g (0.12mol) of solid Mg(NO 3 ) 2 ·6H 2 O and 22.51g (0.06mol) of solid Al(NO 3 ) 3 9H 2 O, dissolved in deionized water, prepared into 150mL mixed salt solution; weighed 14.4g of NaOH and 10.15g (0.06mol) 3-maleimido propionic acid, dissolved in deionized water, prepared into 150mL base solution; at room temperature, the two solutions were added to a rotating membrane reactor at the same flow rate for rapid nucleation, and sodium dodecylsulfonate was added to the slurry at a mass fraction of 5%. The resulting slurry was transferred to a 500mL flask, crystallized at 80°C for 8 hours, centrifuged and washed to a pH of about 7, and dried at 60°C for 12 hours to obtain 3-maleimido propionate intercalated magnesium aluminum hydrotalcite, which The structural formula is Mg 0.64 Al 0.36 (OH) 2 (A - ) 0.36 0.8H 2 O,A - For 3-maleimido propionate.

[0023] Step B: Prepare 2 mL of a mixed solution of ethanol and water with a mass ratio of 95:5, adjust th...

Embodiment 2

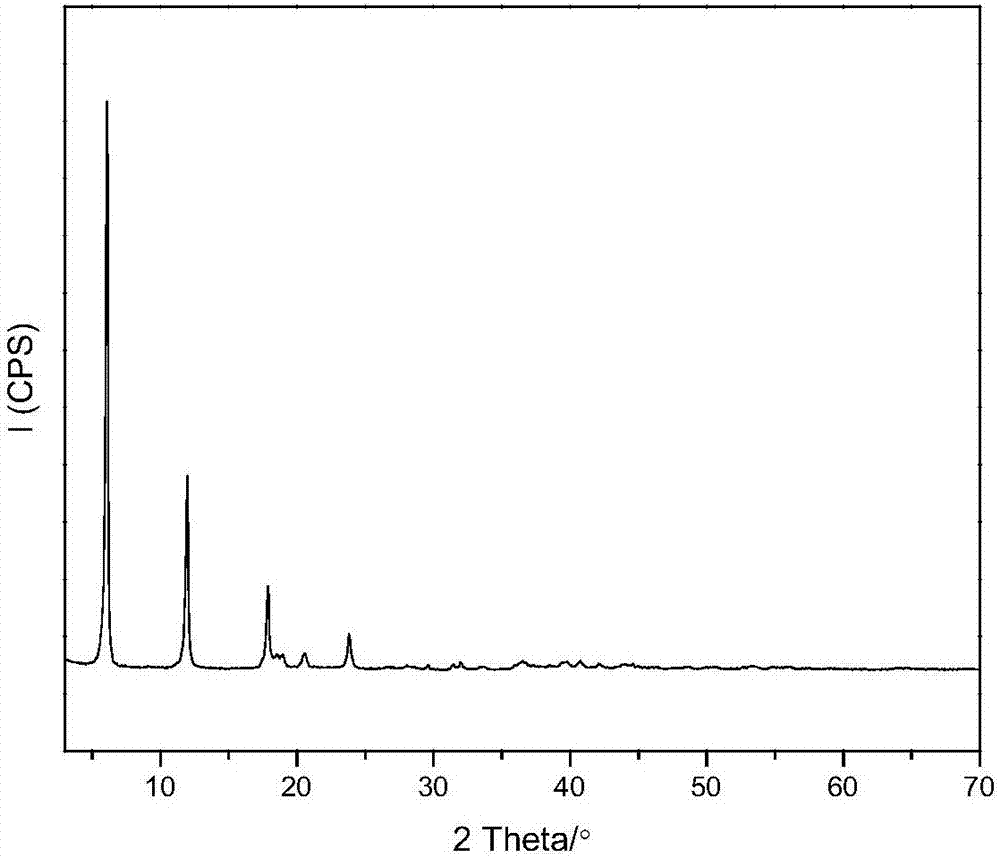

[0026] Step A: 28.34g (0.12mol) of solid Ca(NO 3 ) 2 4H 2 O and 22.51g (0.06mol) of solid Al(NO 3 ) 3 9H 2 O, soluble in removing CO 2 150mL of mixed salt solution was prepared in deionized water; 14.4g of NaOH and 9.55g (0.03mol) of phenolphthalein were weighed and dissolved in 2 Prepare 150 mL of alkali solution in deionized water; add the two solutions into a rotating membrane reactor at the same flow rate at room temperature to quickly nucleate, transfer the obtained slurry to a 500 mL flask, crystallize at 90 ° C for 8 hours, and centrifuge to wash until The pH is about 7, and dried at 60°C for 12 hours to obtain a phenolphthalein quinone-type anion-intercalated calcium-aluminum hydrotalcite precursor, whose structural formula is Ca 0.66 Al 0.34 (OH) 2 (A 2- ) 0.18 ·H 2 O;A 2- For the phenolphthalein anion.

[0027] Step B: Weigh 2.0g CaAl-PPN-LDHs sample, dissolve it in 200ml deionized water, disperse the sample evenly with a magnetic stirrer, then measure 1...

Embodiment 3

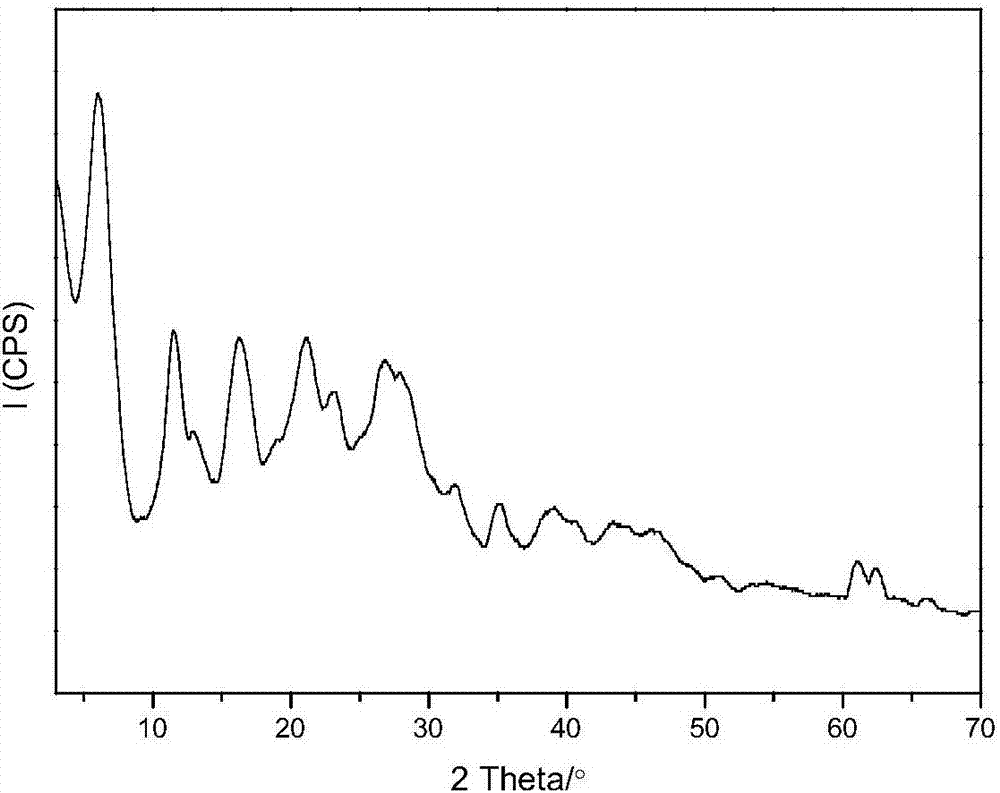

[0030] Step A: 35.70g (0.12mol) of solid Zn(NO 3 ) 2 ·6H 2 O and 15.00g (0.04mol) of solid Al(NO 3 ) 3 9H 2 O, soluble in removing CO 2 150 mL of mixed salt solution was prepared in deionized water; 12.8 g of NaOH and 26.06 g (0.12 mol) of 4-maleimidobenzoic acid were weighed and dissolved in CO 2 Prepare 150mL of alkali solution in deionized water; add the two solutions into the rotating membrane reactor at the same flow rate at room temperature to quickly nucleate, and add sodium dodecylsulfonate to the slurry at a mass fraction of 10%. Transfer the obtained slurry to a 500mL flask, crystallize at 90°C for 8 hours, centrifuge and wash until the pH is about 7, and dry at 60°C for 12 hours to obtain the precursor of nitrate-intercalated zinc-aluminum hydrotalcite, whose structural formula is Zn 0.75 Al 0.25 (OH) 2 (A - ) 0.25 0.9H 2 O,A - For 4-maleimidobenzoic acid ion.

[0031] Step B: Prepare 5mL of a mixed solution of ethanol and water with a mass ratio of 90:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com