Plant-growing pervious concrete system for sludge recycling disposal and preparation method thereof

A permeable concrete and resource-based technology, applied in botany equipment and methods, ceramic products, plant cultivation, etc., can solve the problems of no vegetative concrete, achieve good social and economic benefits, eliminate environmental and safety problems, The effect of high nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

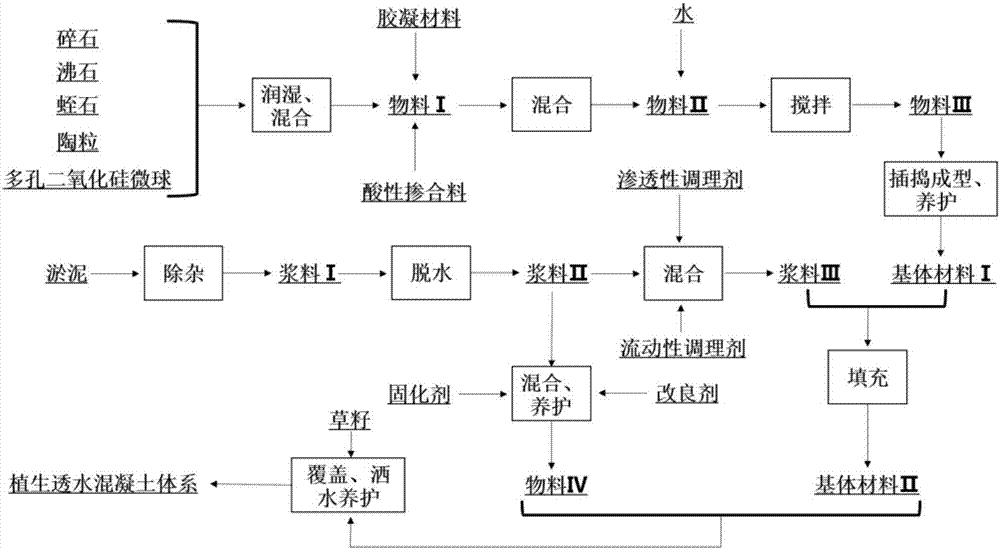

Method used

Image

Examples

Embodiment 1

[0040] A plant-grown permeable concrete system that realizes sludge resource disposal is prepared by the following method:

[0041] (1) Weigh 40kg gravel, 3kg zeolite, 2kg vermiculite, 20kg ceramsite, 5kg porous silica microspheres and mix evenly, add 0.5kg water to wet the surface of the mixed material, obtain material I, and the average particle diameter of material I is 20mm;

[0042] (2) Fully mix the ordinary Portland cement and 4.5kg fly ash of material I and 20kg grade 42.5 grades to obtain material II, and the particle diameters of the ordinary Portland cement and fly ash of the 42.5 grades are 75μm square hole sieve residue ≤ 5%;

[0043] (3) Add 5kg of water to the material II again, add water while stirring to obtain the material III;

[0044] (4) The material III is poured out, inserted and pounded into shape, and the matrix material I with a porosity of 30% is obtained after 3 days of curing, which can be used as the matrix material of the vegetation permeable c...

Embodiment 2

[0052] A plant-grown permeable concrete system that realizes sludge resource disposal is prepared by the following method:

[0053] (1) Take by weighing 20kg gravel, 5kg zeolite, 50kg ceramsite and mix evenly, add 0.5kg water to wet the surface of the mixed material, obtain material I, and the average particle diameter of material I is 30mm;

[0054] (2) Material I is fully mixed with 15kg grade 42.5 ordinary Portland cement and 8kg fly ash to obtain material II. The particle diameters of the 42.5 grade ordinary Portland cement and fly ash are 75 μm Square hole sieve residue ≤ 5%;

[0055] (3) Add 1.5kg of water to the material II again, add water while stirring to obtain the material III;

[0056] (4) Pour out the material III, insert and pound it into shape, and obtain a matrix material I with a porosity of 35% after 3 days of curing, which can be used as a matrix material for a plant-growing permeable concrete system;

[0057] (5) Screening the sludge from dredging to rem...

Embodiment 3

[0064] A plant-grown permeable concrete system that realizes sludge resource disposal is prepared by the following method:

[0065] (1) Take by weighing 30kg gravel, 3kg vermiculite, 30kg ceramsite, 2kg porous silica microspheres and mix uniformly, add 0.8kg water to wet the surface of the mixed material, obtain material I, and the average particle diameter of material I is 35mm; ;

[0066] (2) Material I is fully mixed with 18kg grade 42.5 ordinary Portland cement, 2kg desulfurized gypsum, 8kg coal gangue powder and 2kg acidic slag micropowder to obtain material II, the 42.5 grade ordinary Portland cement, The particle size of desulfurized gypsum, coal gangue powder and acid slag powder is 75 μm square hole sieve ≤ 5%;

[0067] (3) Add 4.2kg of water to the material II again, add water while stirring to obtain the material III;

[0068] (4) The material III is poured out, inserted and pounded into shape, and the matrix material I with a porosity of 36% is obtained after cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com