Monitoring device and monitoring method for corrosion rate of steel rebar in reinforced concrete structure

A technology of reinforced concrete and monitoring devices, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0099] According to the second embodiment of the present invention, a method for monitoring the corrosion rate of steel bars in reinforced concrete structures is provided.

[0100] A method for monitoring steel bar corrosion rate in a reinforced concrete structure, the method may further comprise the steps:

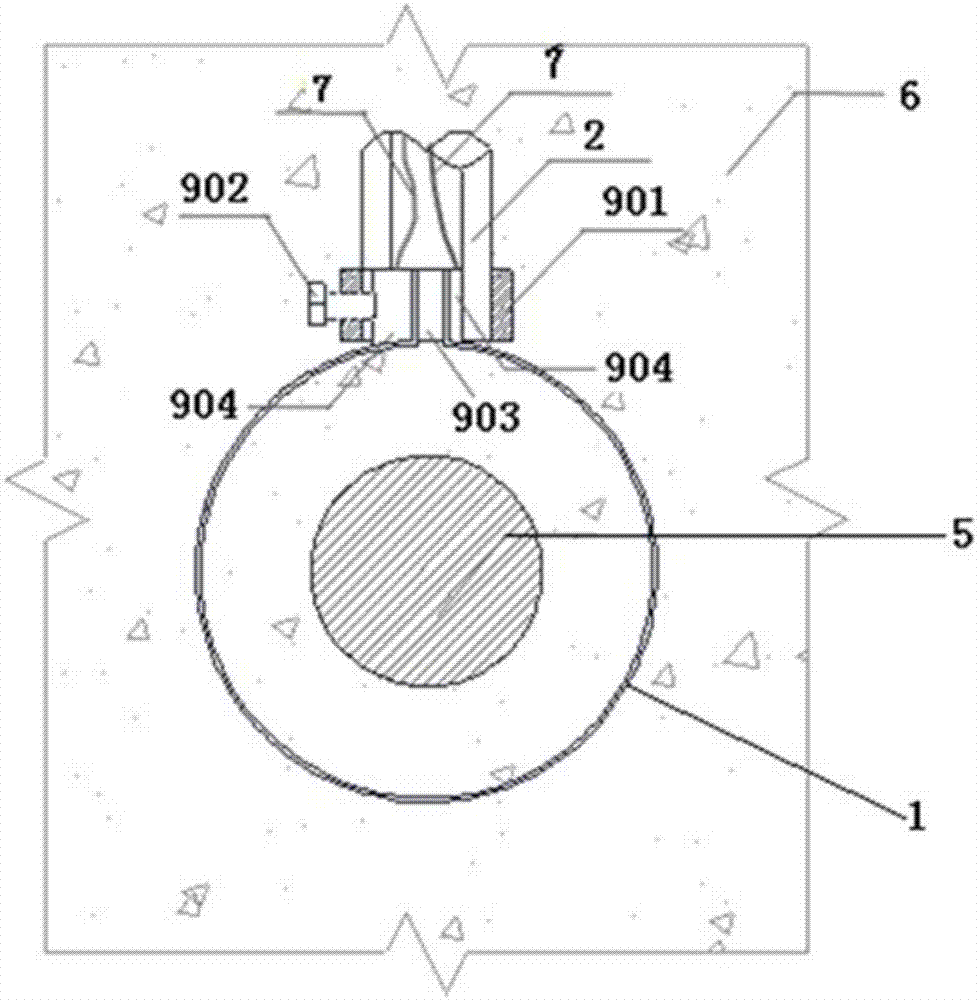

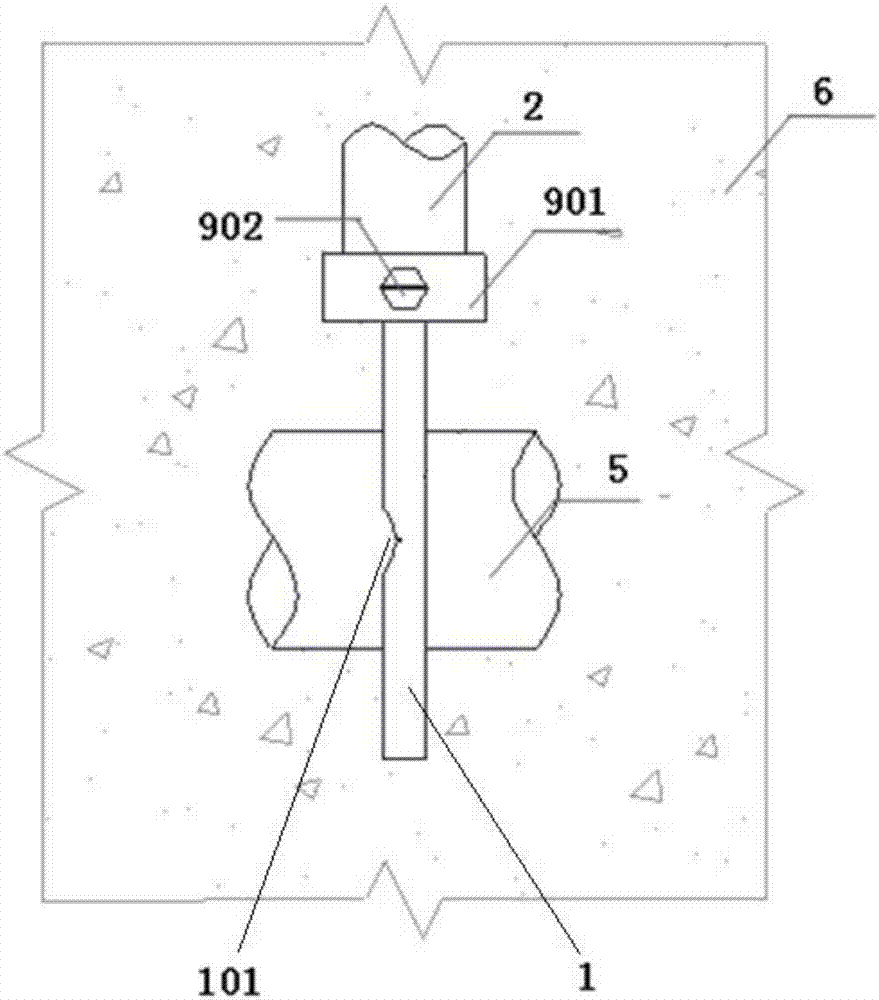

[0101] 1) Determine the outer diameter of the stainless steel ring 1 according to the size of the concrete 6; determine the thickness of the stainless steel ring 1 and the depth of the gap 101 according to the use of the reinforced concrete structure and the surrounding environment; according to the size of the steel bar 5 to be monitored , to determine the size of the gap between the stainless steel ring 1 and the steel bar 5 to be monitored;

[0102] 2) Calculate the breaking stress of the stainless steel ring 1 according to the depth of the notch 101 on the stainless steel ring 1 in step 1) and the thickness of the stainless steel ring 1;

[0103] 3) Installation: Aft...

Embodiment 1

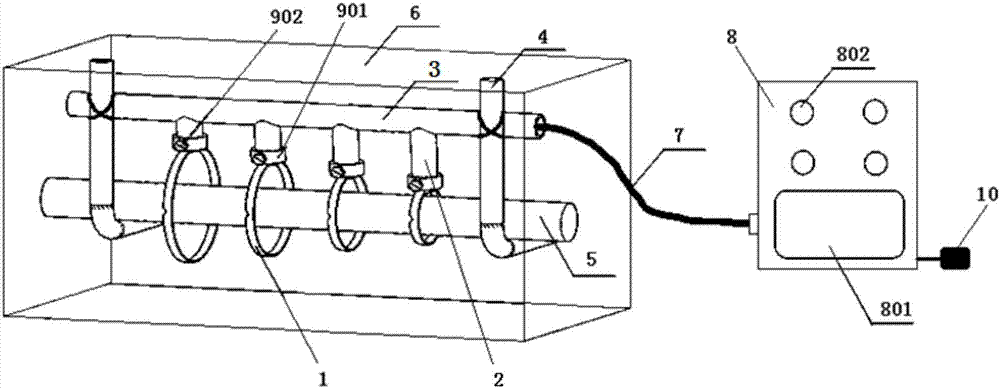

[0111] A monitoring device for steel bar corrosion rate in a reinforced concrete structure, the monitoring device includes a stainless steel ring piece 1, a stainless steel ring piece fixing bracket 2, and a stainless steel ring piece fixing beam 3. The stainless steel ring piece fixes the beam 3 on the stirrup 4. Both the stirrup 4 and the steel bar 5 to be monitored are located in the concrete 6 . One end of the stainless steel ring piece fixed bracket 2 is connected with the stainless steel ring piece fixed beam 3, and the other end of the stainless steel ring piece fixed bracket 2 is connected with the stainless steel ring piece 1. The stainless steel ring piece 1 is a ring structure composed of band-shaped stainless steel pieces separated at both ends. The middle of the stainless steel ring piece 1 is a hollow structure. The steel bar 5 to be monitored passes through the middle of the stainless steel ring piece 1, and there is a gap between the stainless steel ring piec...

Embodiment 2

[0115] Example 1 is repeated, except that a notch 101 is provided on the stainless steel ring 1 , the notch 101 is semicircular, and the depth of the notch 101 is 10% of the width of the stainless steel ring 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com