Polishing agent for liquid crystal touch screen of mobile phone and preparation method of polishing agent

A technology of mobile phone liquid crystal and polishing agent, which is applied to polishing compositions containing abrasives, etc., can solve the problems of low smooth surface coefficient, poor polishing effect, inconvenient use, etc., and achieves high polishing efficiency, improved smoothness, and reaction speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

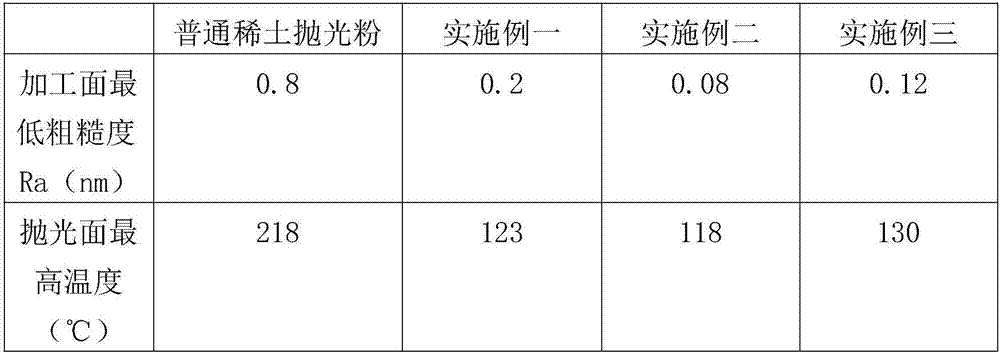

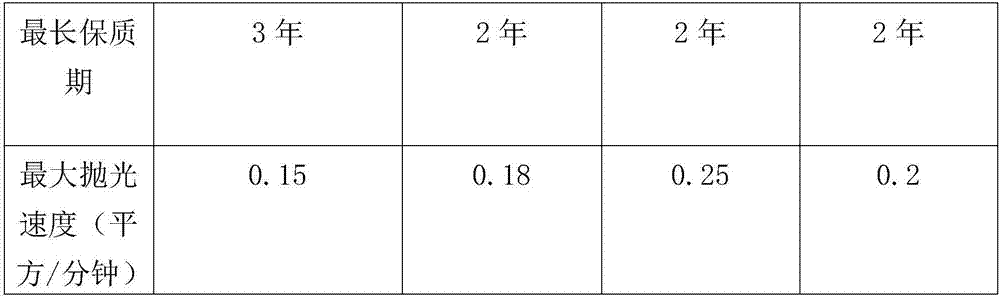

Examples

Embodiment 1

[0024] A mobile phone liquid crystal touch screen polishing agent, comprising the following raw material components by weight, 40 parts of phosphoric acid, 10 parts of concentrated sulfuric acid, 3 parts of chromic acid, 10 parts of glycerin, 4 parts of gelatin, 2 parts of tannin extract, 1 part of glucose, 0.5 parts of disodium edetate, 4 parts of antimony trioxide, 5 parts of titanium dioxide, 10 parts of cerium oxide, 5 parts of rare earth carbonate, 15 parts of water, 1 part of surfactant, 2 parts of flux and defoamer 1 serving.

[0025] The surfactants include 6 parts of fatty acid derivatives, 2 parts of phosphoric acid ester, 3 parts of phoxim, 5 parts of tartaric acid and 1 part of soybean lecithin.

[0026] The auxiliary solvent includes 5 parts of polyacrylamide, 2 parts of polyol, 2 parts of polyether and 1 part of polyurethane.

[0027] The defoamer is 3 parts of emulsified silicone oil and 2 parts of bentonite.

[0028] A preparation method of a mobile phone liq...

Embodiment 2

[0037] A mobile phone liquid crystal touch screen polishing agent, comprising the following raw material components by weight, 45 parts of phosphoric acid, 15 parts of concentrated sulfuric acid, 3.5 parts of chromic acid, 15 parts of glycerin, 5 parts of gelatin, 3 parts of tannin extract, 1.5 parts of glucose, 0.6 parts of disodium edetate, 5 parts of antimony trioxide, 7 parts of titanium dioxide, 15 parts of cerium oxide, 8 parts of rare earth carbonate, 17 parts of water, 2 parts of surfactant, 3 parts of flux and defoamer 1.5 servings.

[0038] Surfactants include 8 parts of fatty acid derivatives, 3 parts of phosphate esters, 4 parts of phoxim, 6 parts of tartaric acid and 2 parts of soybean lecithin.

[0039] The auxiliary solvent includes 6 parts of polyacrylamide, 3 parts of polyol, 3 parts of polyether and 2 parts of polyurethane.

[0040] The defoamer is 5 parts of emulsified silicone oil and 3 parts of bentonite.

[0041] A preparation method of a mobile phone l...

Embodiment 3

[0050] A mobile phone liquid crystal touch screen polishing agent, comprising the following raw material components by weight, 50 parts of phosphoric acid, 20 parts of concentrated sulfuric acid, 4 parts of chromic acid, 20 parts of glycerin, 6 parts of gelatin, 4 parts of tannin extract, 2 parts of glucose, 0.8 parts of disodium edetate, 6 parts of antimony trioxide, 10 parts of titanium dioxide, 20 parts of cerium oxide, 10 parts of rare earth carbonate, 20 parts of water, 3 parts of surfactant, 4 parts of flux and defoamer 2 servings.

[0051] The surfactants include 10 parts of fatty acid derivatives, 4 parts of phosphate, 5 parts of phoxim, 7 parts of tartaric acid and 3 parts of soybean lecithin.

[0052] Co-solvents include 7 parts of polyacrylamide, 4 parts of polyol, 4 parts of polyether and 3 parts of polyurethane.

[0053]The defoamer is 8 parts of emulsified silicone oil and 4 parts of bentonite.

[0054] A preparation method of a mobile phone liquid crystal touc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com