Rapidly-hardened blast furnace hearth repair material and preparation method thereof

A blast furnace furnace and repairing material technology, applied in the field of metallurgical refractory materials, can solve problems such as the fit of ceramic cups and residual carbon bricks, threats to the safe production of blast furnaces, and the rise in temperature of hearth side walls. Good anti-erosion and anti-erosion properties, fast hardening, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of rapid hardening type blast furnace hearth repair material of the present invention, the steps are as follows:

[0043] In parts by weight, first prepare the above-mentioned composite ultrafine powder, dispersant, and coagulant according to the ratio described, and uniformly mix for 5-8 minutes in a double-helix conical mixer to obtain a mixed powder, and take out the mixed powder;

[0044] Then prepare the solid material except the composite superfine powder according to the stated ratio, and uniformly mix with the taken-out mixed powder in a planetary forced mixer for 3-5 minutes to obtain a mixed material;

[0045] Finally, at the construction site, add the sol binder prepared according to the ratio to the obtained mixture, mix evenly in a planetary forced mixer for 5-10 minutes, and stir evenly to obtain a rapid-hardening blast furnace hearth repair material that can be used Pumping construction.

Embodiment

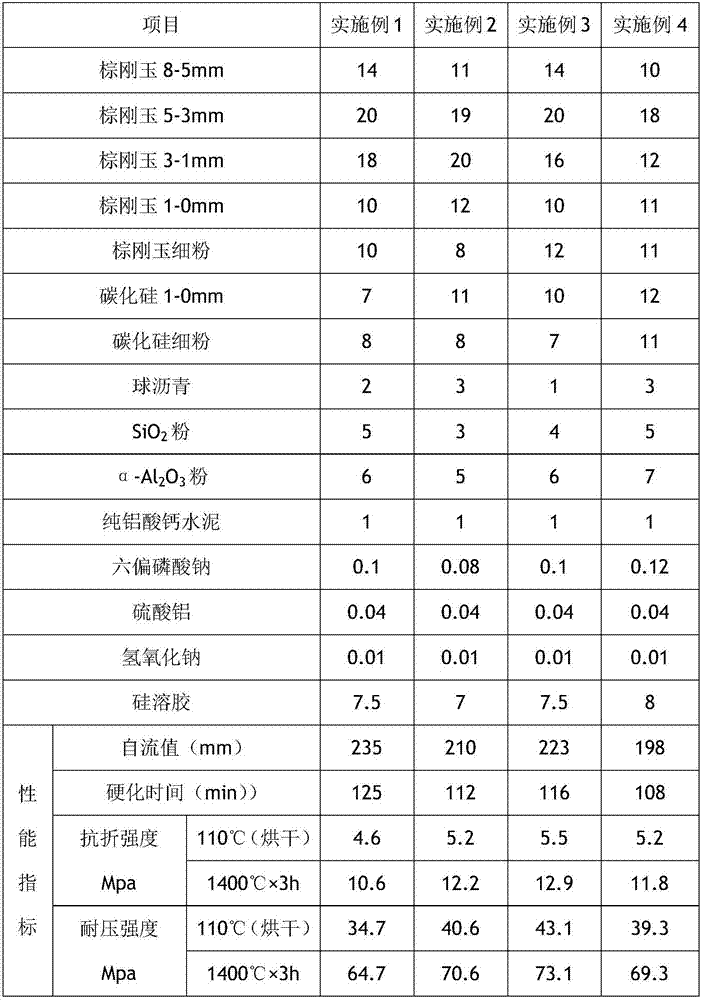

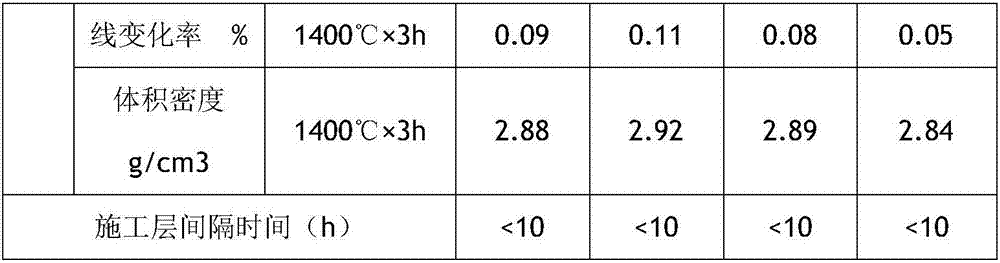

[0048] Table 1 lists the raw materials of each embodiment of the rapid-hardening blast furnace hearth repair material of the present invention, its content measured by weight, and main technical performance indicators.

[0049] Table 1 each embodiment and performance

[0050]

[0051]

[0052] The determination of the self-flow value is to pour the uniformly mixed repair material into the truncated cone mold of the cement mortar fluidity tester, lift the round mold to let the repair material flow on the smooth plate until it stops, and then measure the diameter of the repair material is the self-flow value. The mixed restorative material is poured into a standard mold of 40mm×40mm×160mm to show that the hardening standard is not pressed. The fast-hardening blast furnace hearth repair material of the invention has good self-flowing property and quick hardening. According to the provisions of the national standard, the performance indicators such as flexural strength, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com