Lightweight permeable concrete of iron tailing sludge ceramsite and preparation method of ceramsite

A technology of permeable concrete and lightweight concrete, applied in the field of building materials, can solve the problems of inability to aggregate and affect the safe mining of mines, and achieve the effects of fast construction, full resource utilization, secondary utilization of resources and circular economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Iron tailings sludge ceramsite is a mixture of iron tailings sludge as plastic component, urban sludge as fuel and fly ash as skeleton. After conventional granulation and firing, the firing cost is only 2 / 3 of ordinary ceramsite About sludge ceramsite products, and the solid waste utilization rate of the raw materials used in this product has reached 100%. Convert the residual sludge, fly ash slag, tailings sludge and other solid wastes that will cause secondary environmental pollution in the surrounding urban water treatment around the iron mine into artificial light aggregate products that are urgently needed for the construction of sponge cities. Sludge ceramsite It can completely fix heavy metal ions in municipal sludge.

[0034] The nominal particle diameter of the iron tailings slime is less than 0.6mm, the mud mass content is ≤1.0%, the sulfide and sulfate content is ≤0.5%, and the chloride content is ≤0.02%.

[0035] A preparation method of iron tailings sludge...

Embodiment 2

[0045] Table 2 shows the physical properties of iron tailings sludge ceramsite performance with the amount of municipal sludge added.

[0046] Table 2 Performance of iron tailings sludge ceramsite products with different compositions

[0047] Sample serial number Dry sludge content / (%,wt) Stacking density / (kg m -3 )

[0048] It can be seen from the table that with the increase of the amount of urban sludge, the bulk density of the iron tailings sludge ceramsite sample gradually decreases. When the urban sludge content is 50%, the density of the iron tailings sludge ceramsite sample Bulk density reduced to 760kg m -3 ; When the urban sludge content in the iron tailings sludge ceramsite body is 40%, the fly ash is 35%, and the aggregate tailings is 25%, the iron tailings sludge ceramsite sample after sintering at 1040 ° C has a relatively ideal Excellent light aggregate performance, with a bulk density of 790kg m -3 , Cylinder compressive strength is 5.6MPa, 1h ...

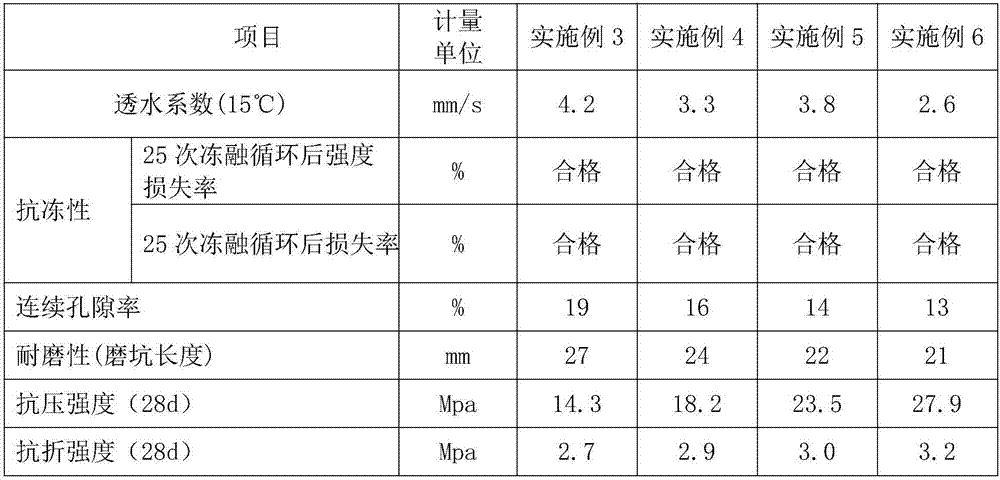

Embodiment 3-6

[0050] Table 3 lists the iron tailings sludge ceramsite lightweight permeable concrete mix ratio (kg m -3 )

[0051] Table 3 Mixing ratio of iron tailings sludge ceramsite lightweight permeable concrete (kg m -3 )

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com