A method for the reuse and treatment of acidic wastewater produced by the preparation of titanium-silicon molecular sieves

A titanium-silicon molecular sieve, acid wastewater technology, applied in ion-exchange water/sewage treatment, natural water treatment, water/sewage treatment, etc., can solve the problem of excessive sulfuric acid-hydrogen peroxide mixture, environmental pollution of waste acid, and safety risks and other problems, to achieve the effect of avoiding emission and post-treatment process, good adsorption performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

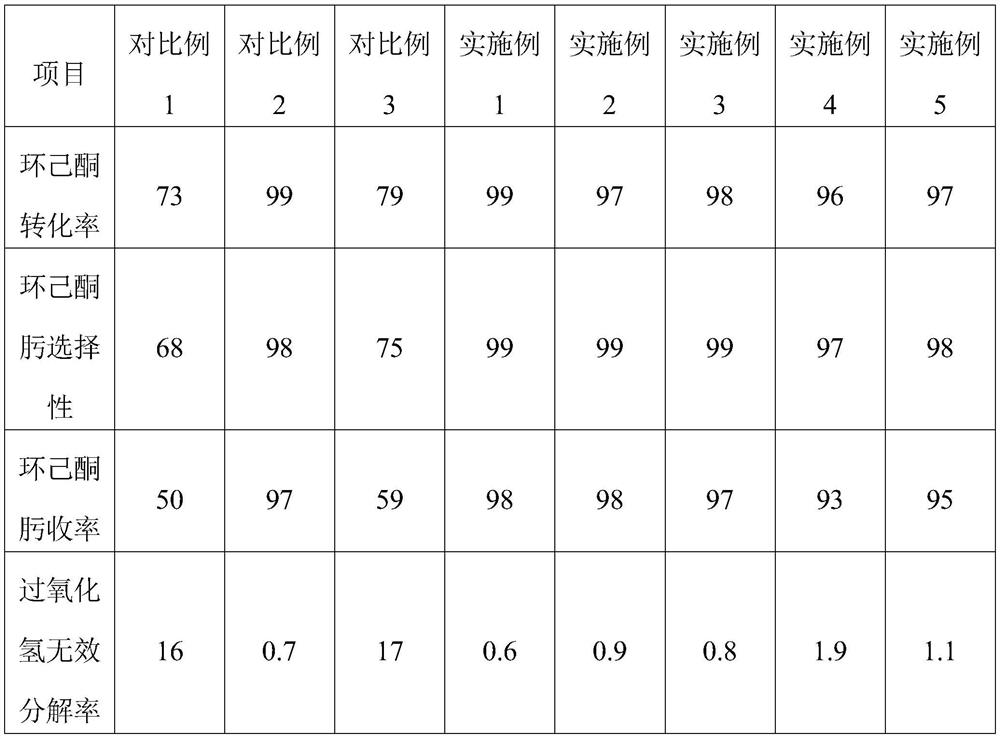

Examples

Embodiment 1

[0037] The preparation process of the regeneration medium: take 100g of hydrogen-type strong acid gel-type styrene-based cation exchange resin with a dry weight of 100g, take 100g of granular activated carbon, mix them evenly, and slowly heat to 200°C in a nitrogen atmosphere to make the hydrogen-type strong acid gel Colloidal styrene-based cation exchange resin is partially carbonized, and the obtained dark brown partial carbide is impregnated with saturated sodium silicate solution and dried at 60°C for 2 hours, then washed with 1600ml of 1.0mol / L dilute hydrochloric acid solution and loaded Packed column as regeneration medium.

[0038] The recovery and treatment process of acidic waste liquid: take 300g of the acidic waste water collected in the above comparative example 2, according to 2h -1 The space velocity is continuously injected from the upper end of the packed column for regeneration treatment, and the filtrate obtained after regeneration treatment, that is, the re...

Embodiment 2

[0042]The preparation process of the regeneration medium: take 50g of hydrogen-type strongly acidic gel-type styrene-based cation exchange resin with a dry weight of 50g, take 150g of granular activated carbon, mix evenly, and slowly heat to 200°C in a nitrogen atmosphere to make hydrogen-type strong acid gel Colloidal styrene-based cation exchange resin is partially carbonized, and the obtained dark brown partial carbide is impregnated with saturated sodium silicate solution and dried at 60°C for 2 hours, then washed with 1600ml of 0.5mol / L dilute hydrochloric acid solution and loaded Packed column as regeneration medium.

[0043] The recovery and treatment process of acidic waste liquid: take 300g of the acidic waste water collected in the above comparative example 2, according to 0.5h -1 The space velocity is continuously injected from the upper end of the packed column for regeneration treatment, and the filtrate obtained after regeneration treatment, that is, the recovere...

Embodiment 3

[0047] The preparation process of the regeneration medium: take a hydrogen-type strong acid gel-type styrene-based cation exchange resin with a dry weight of 150g, take 50g of granular activated carbon, mix them evenly, and slowly heat to 250°C in a nitrogen atmosphere to make the hydrogen-type strong acid gel. Colloidal styrene-based cation exchange resin is partially carbonized, and the obtained dark brown partial carbide is impregnated with saturated sodium silicate solution and dried at 100°C for 0.5h, then washed with 2400m1.5mol / L dilute hydrochloric acid solution and loaded into a packed column as a regeneration medium.

[0048] The recovery and treatment process of acidic waste liquid: take 300g of the acidic waste water collected in the above comparative example 2, according to 5h -1 The space velocity is continuously injected from the upper end of the packed column for regeneration treatment, and the filtrate obtained after regeneration treatment, that is, the recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com