MoSxOy/carbon nanometer composite material, and preparation method and application thereof

一种纳米复合材料、复合材料的技术,应用在纳米碳、燃料电池、收集器/分离器等方向,能够解决复合材料催化性能差距等问题,达到良好催化稳定性、增强催化能力、增加数目的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides the aforementioned nanocomposite preparation method, wherein the method comprises the following steps:

[0036] (1) Dispersing the carbon source in a solvent, preferably ultrasonically dispersing for 30-100 minutes, to obtain a carbon source dispersion;

[0037] In the specific implementation process of step (1), the proportioning of the carbon source and the solvent is 1-10 mg: 1 mL; the carbon source is preferably selected from carbon black, carbon nanotubes, carbon nanohorns, graphite oxide, sulfonated graphite oxide At least one; the solvent is preferably at least one selected from ethylene glycol, glycerol, water, preferably deionized water; in the specific implementation process, ultrasonic dispersion is more preferably 60-100 minutes; ultrasonic power can be 500 -1200W.

[0038] (2) adding the sulfur source and the molybdenum source to the carbon source dispersion to obtain a mixed solution;

[0039] In the specific implement...

Embodiment 1

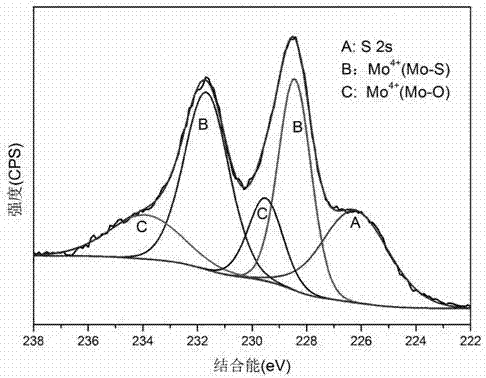

[0051] Example 1: MoS x o y / Preparation and application of carbon nanocomposites

[0052] Preparation of MoS x o y / Carbon Nanocomposite

[0053] Disperse 80mg of acetylene black into 20ml of ethylene glycol (4mg / mL), and ultrasonically disperse with an ultrasonic processor for 60 minutes at room temperature (ultrasonic power 650W) to obtain the acetylene black dispersion; subsequently, add 40mg of ammonium tetrathiomolybdate , to obtain the mixed solution; transfer it to a radiant tube, feed high-purity nitrogen for 30 minutes, seal it with a rubber stopper, and place it in 60 Irradiation was carried out at room temperature in a Coγ-ray irradiation device with a dose rate of 50Gy / min and an absorbed dose of 50kGy. After the irradiation, the sample was filtered through a polypropylene (PP) membrane with a pore size of 0.45 μm. The filter cake after filtration is rinsed with ethanol, and then washed with deionized water after filtration. Each time it is washed, it is tr...

Embodiment 2

[0063] Example 2: MoS x o y / Preparation of carbon nanocomposites

[0064] Change the acetylene black in embodiment 1 into carbon nanotubes, and other preparation conditions of the composite material are the same as embodiment 1, and prepare MoS under this condition x o y / Carbon Nanocomposite, MoS x o y The mass percentage in the composite material is 17%, x is 2.91, and y is 0.58.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com