Free bending forming method for spiral three-dimensional complex bent piece

A bending forming and spiral technology, which is applied in the field of free bending forming of spiral three-dimensional complex curved parts, can solve the problems of difficult control of bending radius and pitch, large equipment investment, and increased manufacturing cost, and achieve important engineering application value, Obvious economic benefit, simple and feasible method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

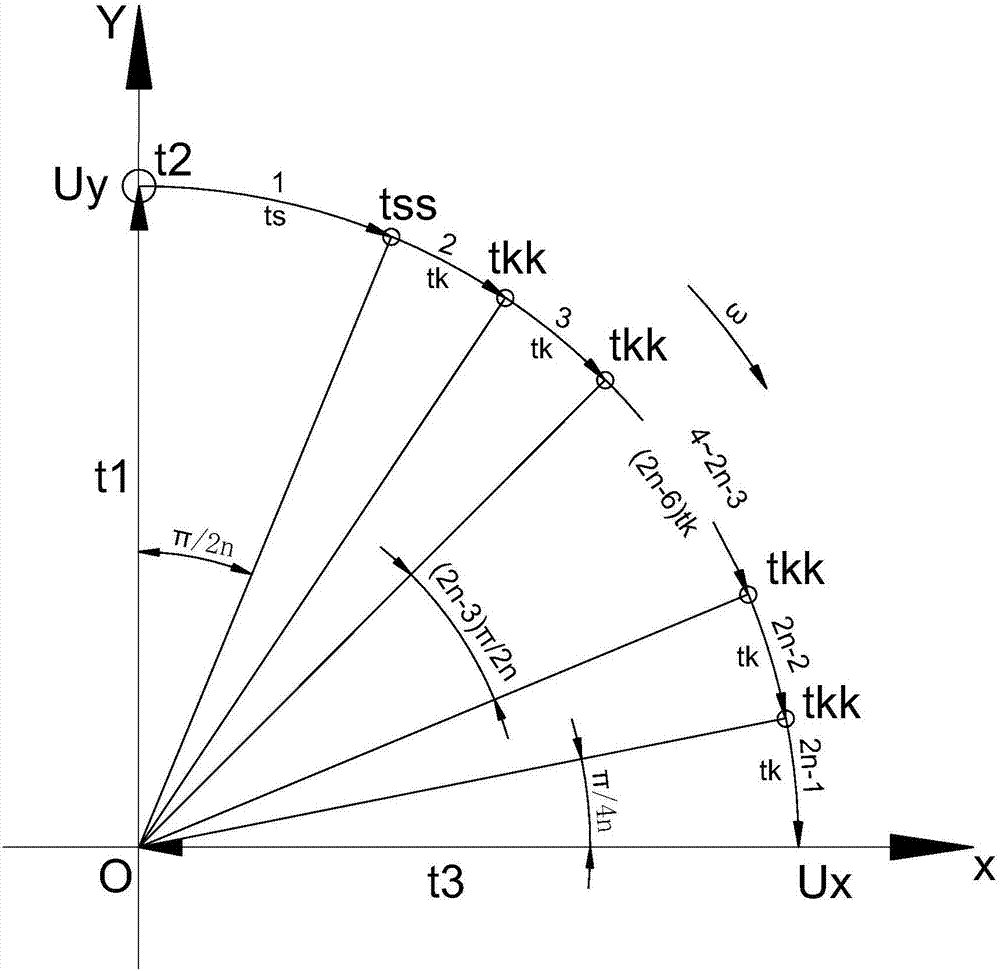

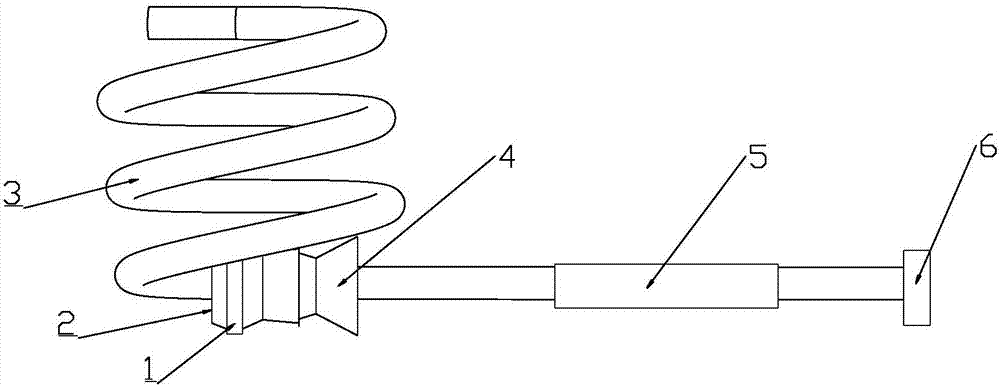

[0047] Figure 4 It is a spiral three-dimensional complex curved part with a cylindrical diameter of 120mm, a pitch of 30mm, a number of spiral turns of 2, and a pipe outer diameter of 15mm. The specific forming process steps are as follows:

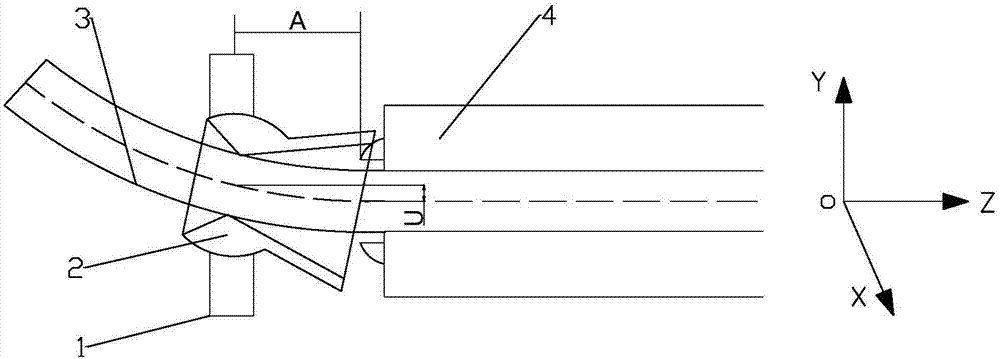

[0048] First, determine the bending radius R=D / 2=60mm according to the diameter of the cylinder D=120mm, and determine according to the bending radius 60mm, the moving speed of the pipe in the Z direction v=20mm / s and the distance A=30mm between the center of the bending die and the front end of the guiding mechanism Y-direction eccentricity Uy, movement time t1 and residence time t2;

[0049]

[0050]

[0051]

[0052]

[0053] Second, according to the number of spiral turns n=2, determine the number of deflection N of the bending die and the angle θn of each deflection during the movement of the bending die from the Uy position to the Ux position;

[0054] N=2n-1=2×2-1=3

[0055]

[0056] Third, calculate the single-tu...

Embodiment 2

[0066] Figure 5 It is a helical three-dimensional complex curved part with a cylindrical diameter of 150 mm, a pitch of 15 mm, a number of helical turns of 5, and a pipe outer diameter of 6 mm. The specific forming process steps are as follows:

[0067] First, determine the bending radius R=D / 2=75mm according to the diameter of the cylinder D=150mm, and determine according to the bending radius 75mm, the moving speed of the pipe in the Z direction v=20mm / s and the distance A=30mm between the center of the bending die and the front end of the guiding mechanism Y-direction eccentricity Uy, movement time t1 and residence time t2;

[0068]

[0069]

[0070]

[0071] Second, according to the number of spiral turns n=3, determine the number of deflection N of the bending die and the angle θn of each deflection during the movement of the bending die from the Uy position to the Ux position;

[0072] N=2n-1=2×3-1=5

[0073]

[0074] Third, calculate the single-turn spira...

Embodiment 3

[0084] Figure 6 It is a helical three-dimensional complex curved part with a cylindrical diameter of 200mm, a pitch of 10mm, a number of helical turns of 10, and a pipe outer diameter of 4mm. The specific forming process steps are as follows:

[0085] First, determine the bending radius R=D / 2=100mm according to the diameter of the cylinder D=200mm, and determine according to the bending radius 100mm, the moving speed of the pipe in the Z direction v=20mm / s and the distance A=30mm between the center of the bending die and the front end of the guiding mechanism Y-direction eccentricity Uy, movement time t1 and residence time t2;

[0086]

[0087]

[0088]

[0089] Second, determine the deflection times N of the bending die and the angle θn of each deflection during the movement of the bending die from the Uy position to the Ux position according to the number of spiral turns n=10;

[0090] N=2n-1=2×10-1=19

[0091]

[0092] Third, calculate the length L of the sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com