High-dispersion particle catalyst applied to synthesis of hydrogen peroxide as well as preparation method and application thereof

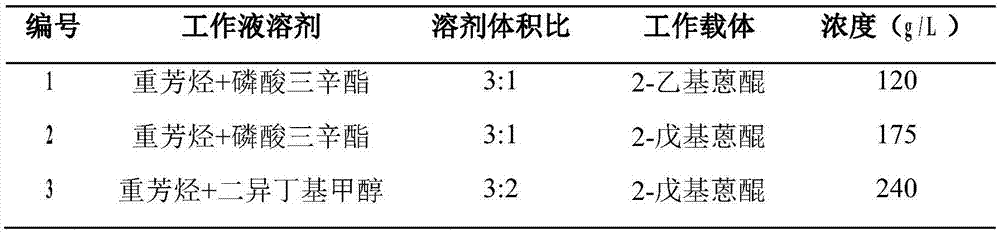

A particle catalyst, catalyst technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of reducing precious metal content, poor selectivity, low hydrogenation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] a) Weigh 0.2g AlPO-11, 0.8g Al 2 o 3 , after mixing evenly, tableting and granulation, the tableting pressure is 5MPa, and the particle size is 20-30 mesh.

[0070] b) Take 3mg La(NO 3 ) 3 ·6H 2 O dissolved in 5ml of water forms La(NO 3 ) 3 solution, immerse the particles obtained in step 1) in the solution for 2 hours, and then dry at 80° C. for 12 hours to obtain a carrier.

[0071] c) Take 0.5g carrier and impregnate it in 1ml of H2O with a concentration of 0.6mg / ml 2 PtCl 6 solution (calculated as Pt), the immersion time is 2h.

[0072] d) Dry at 80°C for 12h and then calcinate at 400°C for 2h to obtain the catalyst in oxidation state.

[0073] e) Put the oxidized catalyst in 20ml of formaldehyde solution (0.1M) for reduction, the reduction temperature is controlled at 60°C, the reduction time is 1h, and then rinsed with deionized water and dried at room temperature to obtain catalyst A.

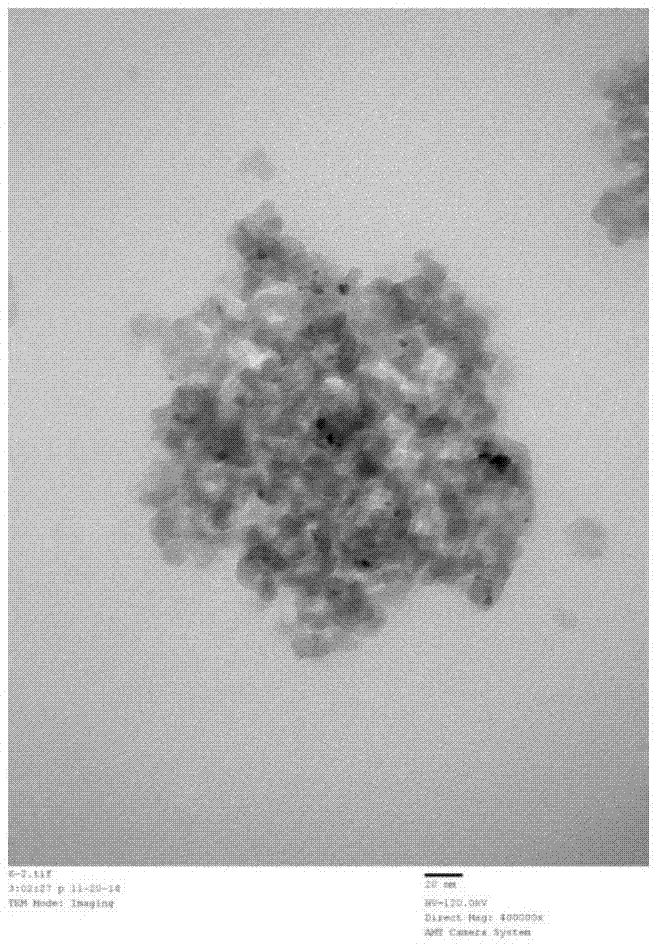

[0074] TEM photo see figure 1 , and the evaluation results of cata...

Embodiment 2

[0076] a) Weigh 0.4g SAPO-34, 0.6g SiO 2 , 0.1g of silica sol (40wt%) and 20ml of deionized water, mixed evenly, dried at 80°C, and granulated, with a particle size of 10-20 mesh.

[0077] b) Take 0.64g Mg(NO 3 ) 2 ·6H 2 O dissolved in 5ml of water to form Mg(NO 3 ) 2 solution, immerse the particles obtained in step 1) in the solution for 2 hours, and then dry at 80° C. for 12 hours to obtain a carrier.

[0078] c) Take 0.5g carrier and impregnate it in 1ml of H2O with a concentration of 3mg / ml 2 PdCl 4 solution (calculated as Pd), the immersion time is 2h.

[0079] d) After drying at 80°C for 12h, calcining at 300°C for 2h to obtain the catalyst in the oxidized state.

[0080] e) Place the oxidation state catalyst in H 2 Reduction in the atmosphere, the reduction temperature is 60 ° C, and the reduction time is 24 hours to obtain catalyst B.

[0081] The evaluation results of catalyst hydrogenation performance are shown in Table 2.

Embodiment 3

[0083] a) Weigh 0.6g VPI-5, 0.4g CeO 2 , 0.1g cerium sol (10wt.%), 0.52g Nd(NO 3 ) 3 ·6H 2 O and 20ml of deionized water were evenly mixed, dried at 120°C, and granulated to obtain a carrier with a particle size of 10-20 mesh.

[0084] b) Take 0.5g carrier and impregnate it in 1ml Pd(NO 3 ) 2 solution (calculated as Pd), the immersion time is 2h.

[0085] c) Vacuum drying at 60°C for 12 hours and then calcining at 250°C for 2 hours to obtain the catalyst in an oxidized state.

[0086] d) Put the oxidation state catalyst in NaBH 4 Reduction in a solution (10wt%), the reduction time is 1 h, the reduction temperature is 30 degrees, and then washed with deionized water and dried at room temperature to obtain catalyst C.

[0087] The evaluation results of catalyst hydrogenation performance are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com