Semi-elliptical projector comprising a radiator

A technology for floodlights and radiators, applied in the field of floodlights, can solve the problems of large volume, expensive, heavy, etc., to optimize the space, improve the diffusion of heat, and improve the effect of cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

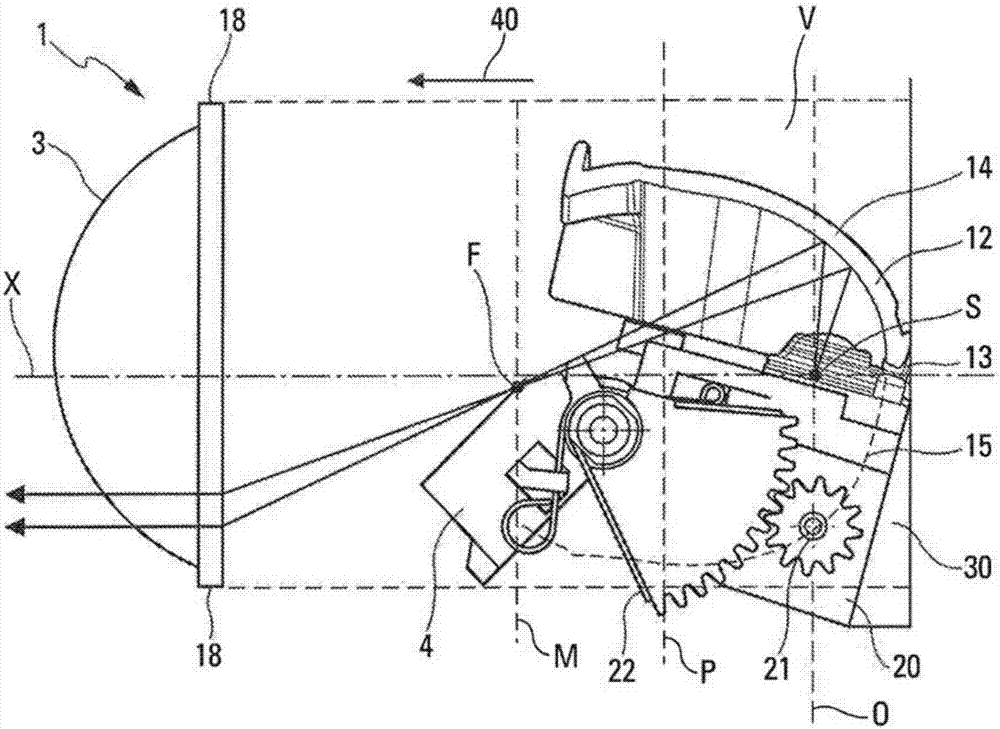

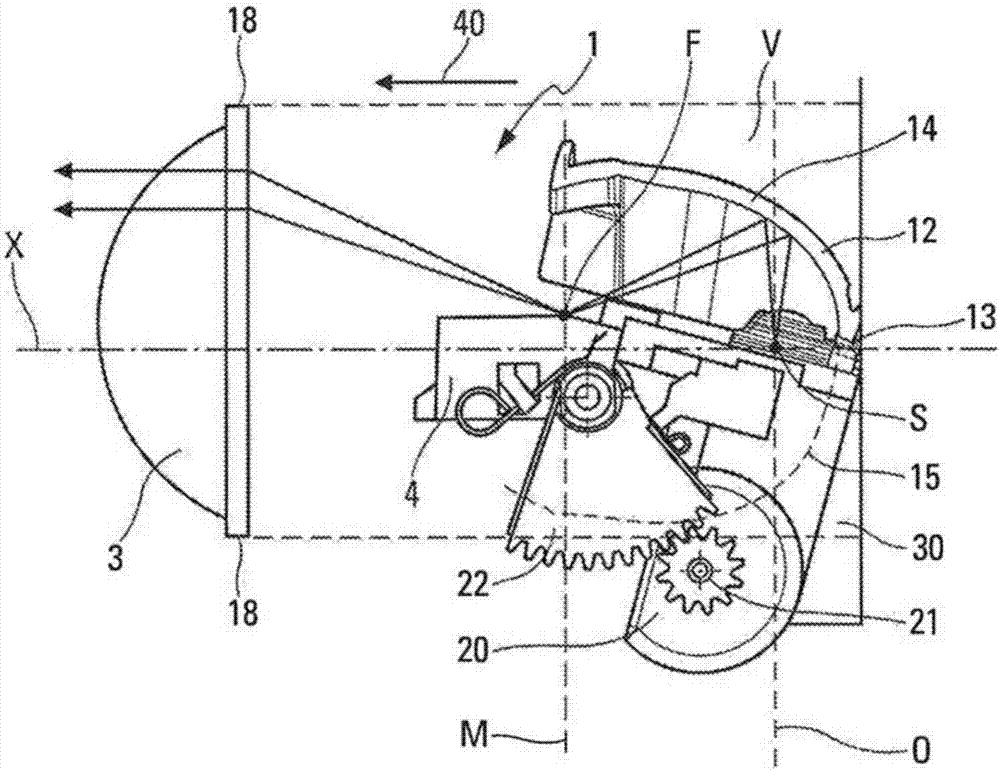

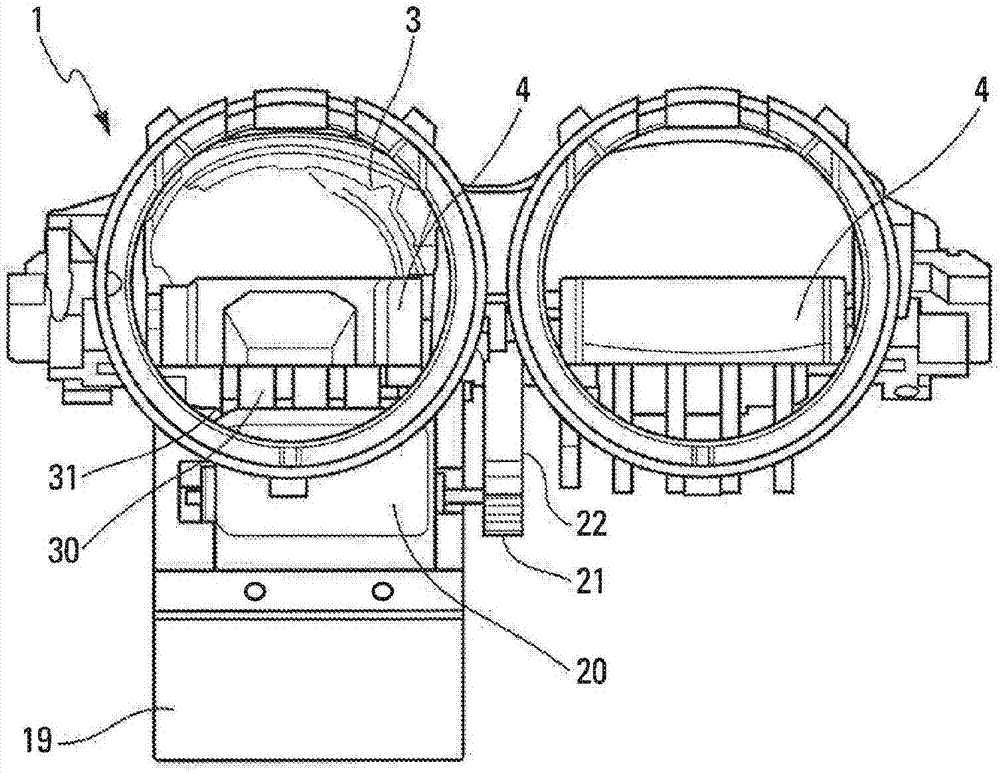

[0030] refer to figure 1 and figure 2 , the drawing shows a semi-elliptical floodlight 1 for a motor vehicle comprising a reflector 12 in the form of a first semi-ellipsoid part extending above the plane of symmetry of the ellipsoid . The floodlight also includes a light source S including a light emitting diode (LED) placed inside the reflective portion. In this case, the light source comprises a plurality of LED diodes. The second semi-ellipsoid part 15 combined with the first semi-ellipsoid part 14 to constitute the ellipsoid part is shown in dotted lines to facilitate understanding, but it does not represent a real physical element of the semi-ellipse floodlight. The second semi-ellipsoid part 15 is symmetrical to the first semi-ellipsoid part 14 about the plane of symmetry of the ellipsoid. The first semi-ellipsoid part is bounded in the axial direction by a plane M which is perpendicular to the axis of symmetry of the ellipsoid and which intersects the ellipsoid.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com