(Porous support)-(zeolite membrane) assembly, and method for producing (porous support)-(zeolite membrane) assembly

A manufacturing method and a technology for a support body, which are applied in separation methods, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problems of limited application scope, low heat resistance, and low chemical resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

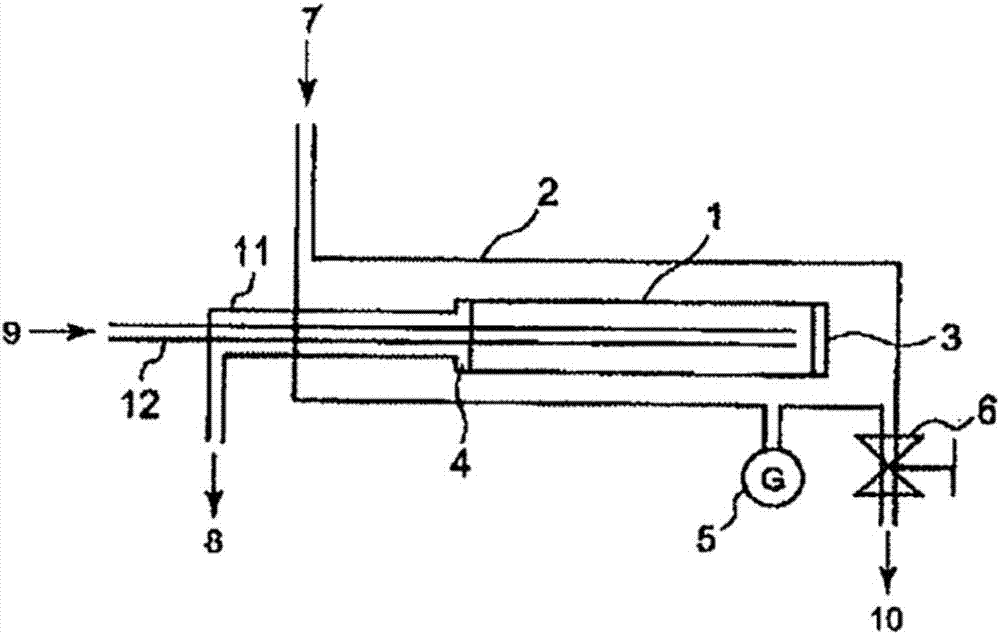

Method used

Image

Examples

Embodiment 1

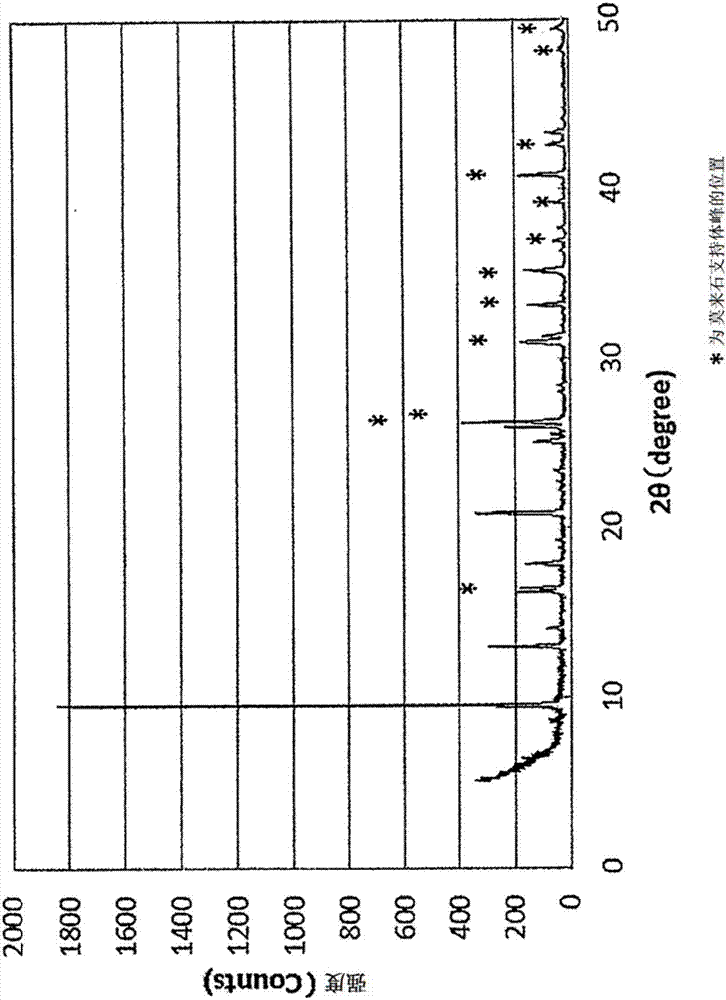

[0256] A porous support is produced by attaching fumed silica (AEROSIL 300, manufactured by Nippon Aerosil Co., Ltd.) as inorganic particles on a porous support made of mullite, and then directly hydrothermally synthesizing a CHA-type aluminosilicate zeolite. Body-CHA type zeolite membrane complex.

[0257] The reaction mixture for hydrothermal synthesis was prepared as follows.

[0258] Add aluminum hydroxide (containing Al 2 o 3 53.5% by mass, manufactured by Aldrich) 0.195 g was stirred to dissolve, and 114 g of demineralized water was further added and stirred to obtain a transparent solution. To this transparent solution, 2.4 g of an aqueous solution of N,N,N-trimethyl-1-adamantyl ammonium hydroxide (hereinafter referred to as "TMADAOH") (containing 25% by mass of TMADAOH, manufactured by SACHEM) was added as an organic template, Furthermore, 110.8 g of colloidal silica (Snowtec-40 manufactured by Nissan Chemical Co., Ltd.) was added and stirred for 30 minutes to prepa...

Embodiment 2

[0274] A porous support-zeolite membrane composite was obtained in the same manner as in Example 1, except that the conditions for attaching fumed silica (AEROSI 300, manufactured by Nippon Aerosi Co., Ltd.) were changed.

[0275] The porous support was immersed in a 0.3% by mass dispersion liquid obtained by dispersing fumed silica in water, and the fumed silica was adhered by an impregnation method. Then, it dried at 140 degreeC for 1 hour. The weight change after drying is 0.42g / m 2 . In addition, the mass increase after the seed crystal was attached and dried was 2.3 g / m 2 , the mass of CHA-type zeolite calculated from the weight gain after film making and sintering is 121g / m 2 .

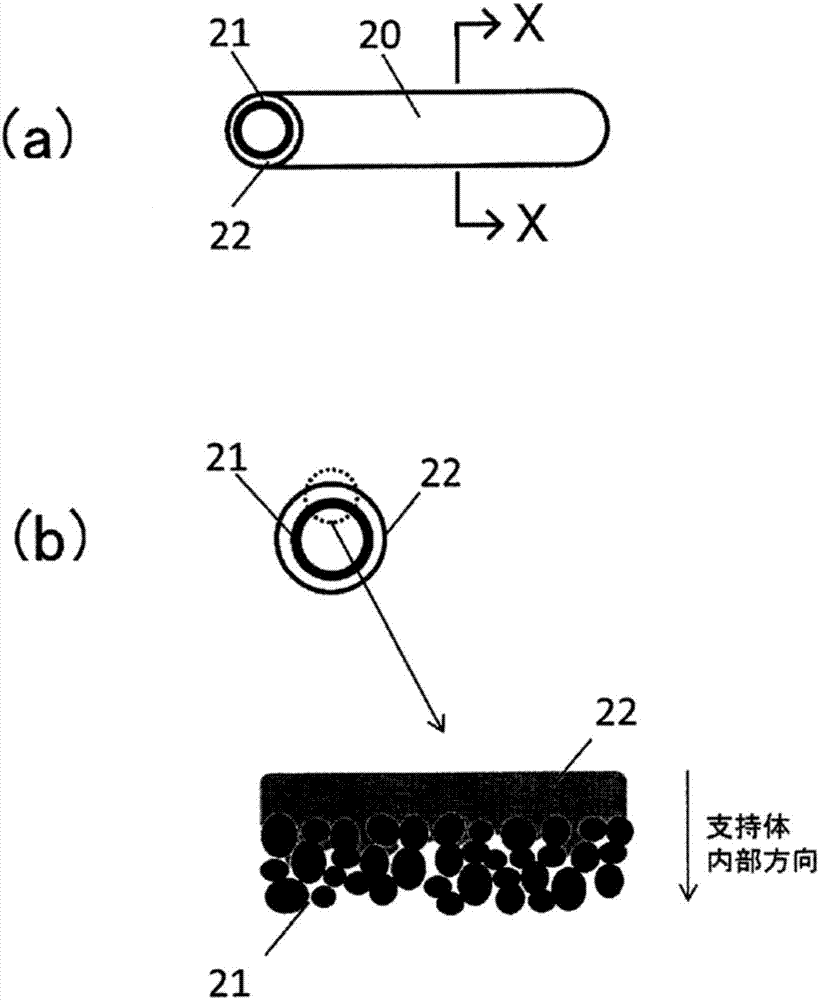

[0276] In addition, cut out an arbitrary part of the cross-section, and observe the smooth surface with a cross-section polishing machine at a magnification of 2000 times, and measure the weighted average value of the distance from the surface of the porous support from the images of the obt...

Embodiment 3

[0281] The tube of the ceramic sintered body was cut into a length of 80 mm, washed with demineralized water, dried, and used as a porous support. The average pore diameter of this porous support was about 0.9 μm.

[0282] As the seed crystal, a CHA-type zeolite having an average particle diameter of about 1.2 μm was used. The seed crystal was dispersed in 1% by mass of water to obtain a dispersion liquid, and the above-mentioned support was immersed in the dispersion liquid for a predetermined time to attach the seed crystal by the dipping method, and dried at 140° C. for 1 hour or more to attach the seed crystal.

[0283] The support to which the seed crystal was attached was immersed in a vertical direction in an inner cylinder (200 ml) made of Teflon (registered trademark) to which the same aqueous reaction mixture as in Example 1 was added, the autoclave was sealed, and autogenous Under pressure, heat at rest for about 18 hours. After a predetermined period of time, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com