Waterborne slurry used for coating lithium ion battery diaphragm and preparation method for waterborne slurry

A technology of lithium-ion batteries and water-based slurry, which is applied to battery pack components, separators/films/diaphragms/spacers, circuits, etc. Poor heat resistance and other problems, to achieve the effect of good coating performance, strong repeatability and strong processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

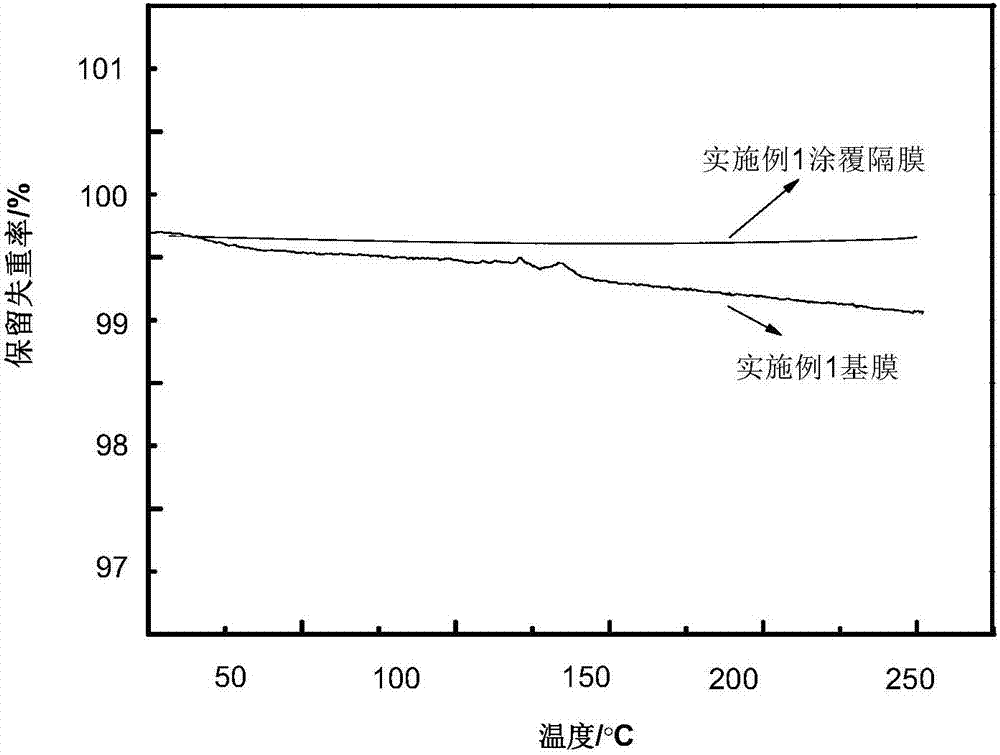

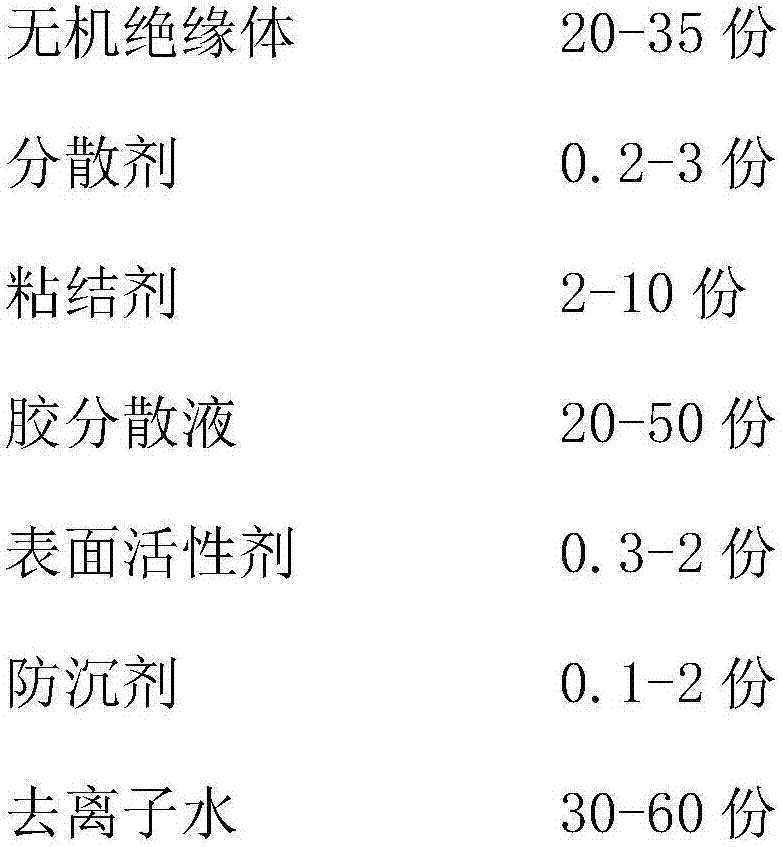

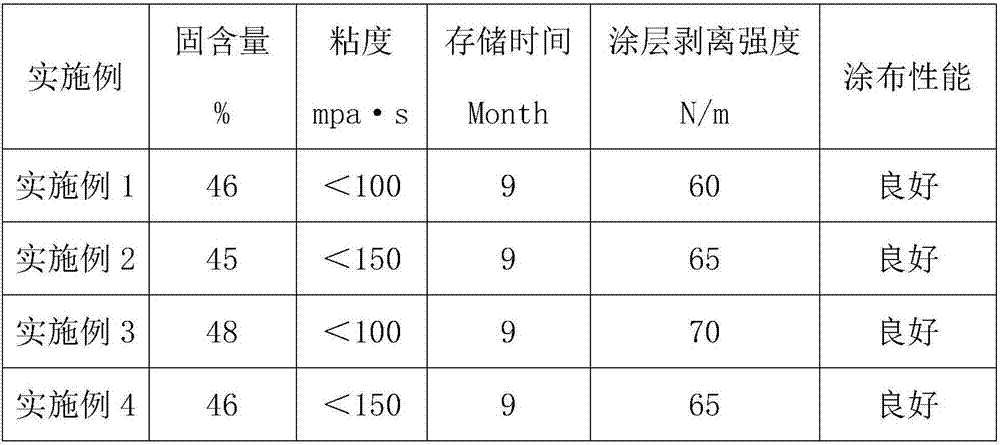

Embodiment 1

[0026] Add 30 parts of aluminum oxide, 0.4 parts of polyacrylic acid ammonium salt copolymerization solution, 0.1 part of synthetic phyllosilicate solution and 40 parts of deionized water into the disperser, control the temperature of the disperser to 25°C, and the power to 2000W. Disperse for 1.5 hours, then add 3 parts of water-based polypropionic acid modified resin, 26 parts of glue dispersion, and 0.5 parts of polyether modified silicone surfactant to the disperser, keep the temperature of the disperser at 25°C and the power at 400W , and continue to disperse for 1 hour to pass through a 200-mesh sieve to obtain a slurry. Use a coating machine to evenly coat the slurry on the surface of the PE base film, and then dry it to obtain a new type of coated separator for lithium-ion batteries. The speed of the coating machine is controlled at 50 m / min, and the oven temperature is 65°C.

Embodiment 2

[0028] Add 28 parts of boehmite, 1 part of polyvinylpyrrolidone solution, 0.6 part of sodium hydroxymethylcellulose solution and 40 parts of deionized water into the disperser, control the temperature of the disperser at 30°C, and the power of 2500W, and disperse for 1 hour , then add 5 parts of water-based polyvinyl alcohol, 25 parts of glue dispersion, 0.4 parts of water-based non-ionic fluorocarbon surfactant, keep the temperature of the disperser at 30°C, and the power of 500W, and continue to disperse for 0.5 hours to pass through a 200-mesh screen , get slurry. Use a coating machine to evenly coat the slurry on the surface of the PP base film, and then dry it to obtain a new type of coated separator for lithium-ion batteries. The speed of the coating machine is controlled at 40 m / min, and the oven temperature is 60 °C.

Embodiment 3

[0030] Add 26 parts of boron nitride, 1 part of polyvinyl alcohol solution, 0.4 part of synthetic layered silicate solution and 42 parts of deionized water into the disperser, control the temperature of the disperser at 35°C, and the power of 2200W, and disperse for 1.2 hours , then add 10 parts of water-based acrylonitrile, 30 parts of glue dispersion, and 0.6 parts of water-based anionic fluorocarbon surfactant, keep the temperature of the disperser at 35°C, and the power of 600W, and continue to disperse for 0.4 hours to pass through a 200-mesh screen to obtain slurry. Use a coating machine to evenly coat the slurry on the surface of the PE base film, and then dry it to obtain a new type of coated separator for lithium-ion batteries. The speed of the coating machine is controlled at 45 m / min, and the oven temperature is 65 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com