Method and device for the production of synthetic staple fibers

A technology for synthesizing staple fibers and equipment, which is applied in the field of manufacturing synthetic staple fibers/cut fibers, and can solve problems such as the inability to achieve constant guide tow and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

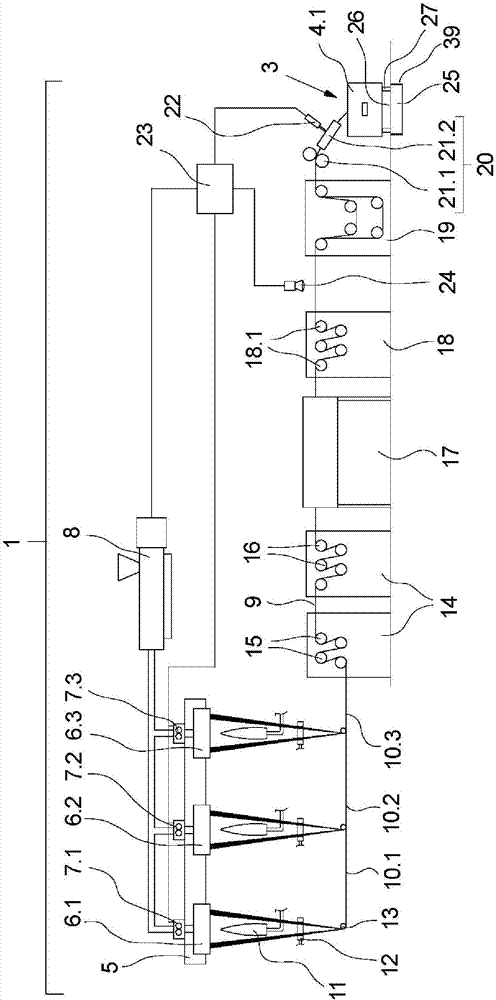

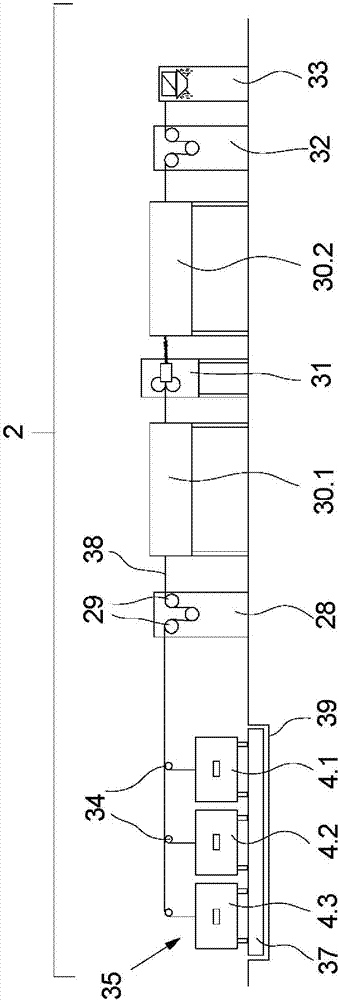

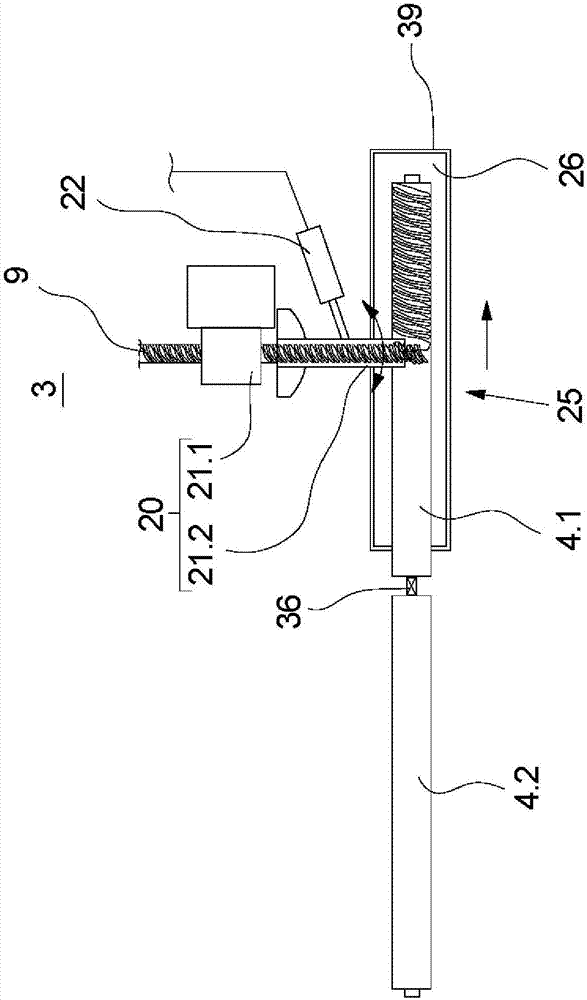

[0035] exist Figures 1 to 4 An embodiment of a device according to the invention is shown in several views. figure 1 shows a side view of the melt-spinning apparatus, figure 2 shows a side view of the fiber processing device arranged behind, Figure 3.1 schematically shows a top view of the laying station, Figure 3.2 schematically shows a front view of the laying station, Figure 4 A top view of the can creel is shown schematically. The following description applies to all drawings unless it is explicitly indicated which drawing(s) are referred to.

[0036] exist figure 1An embodiment of a melt-spinning device used in the method according to the invention, for example in an apparatus according to the invention, is shown in , in order to form a plurality of fiber slivers newly extruded from a tow. The melt spinning device 1 has a spinning beam 5, on the bottom side of which a plurality of spinning nozzle units 6.1, 6.2 and 6.3 are arranged. The number of spinning nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com