A Construction Method of Rotary Digging Pile in Hard Rock Formation with Large Dip Angle

A technology of hard rock formations and large inclination angles, applied in the field of construction method of rotary excavation piles in hard rock formations with large inclination angles, can solve the problems of difficulty in meeting the construction needs of rotary excavation piles in hard rock formations with large inclination angles, low construction efficiency, and inclination of drilling holes, etc., to achieve rock drilling High efficiency, fast construction progress, and less drill bit wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

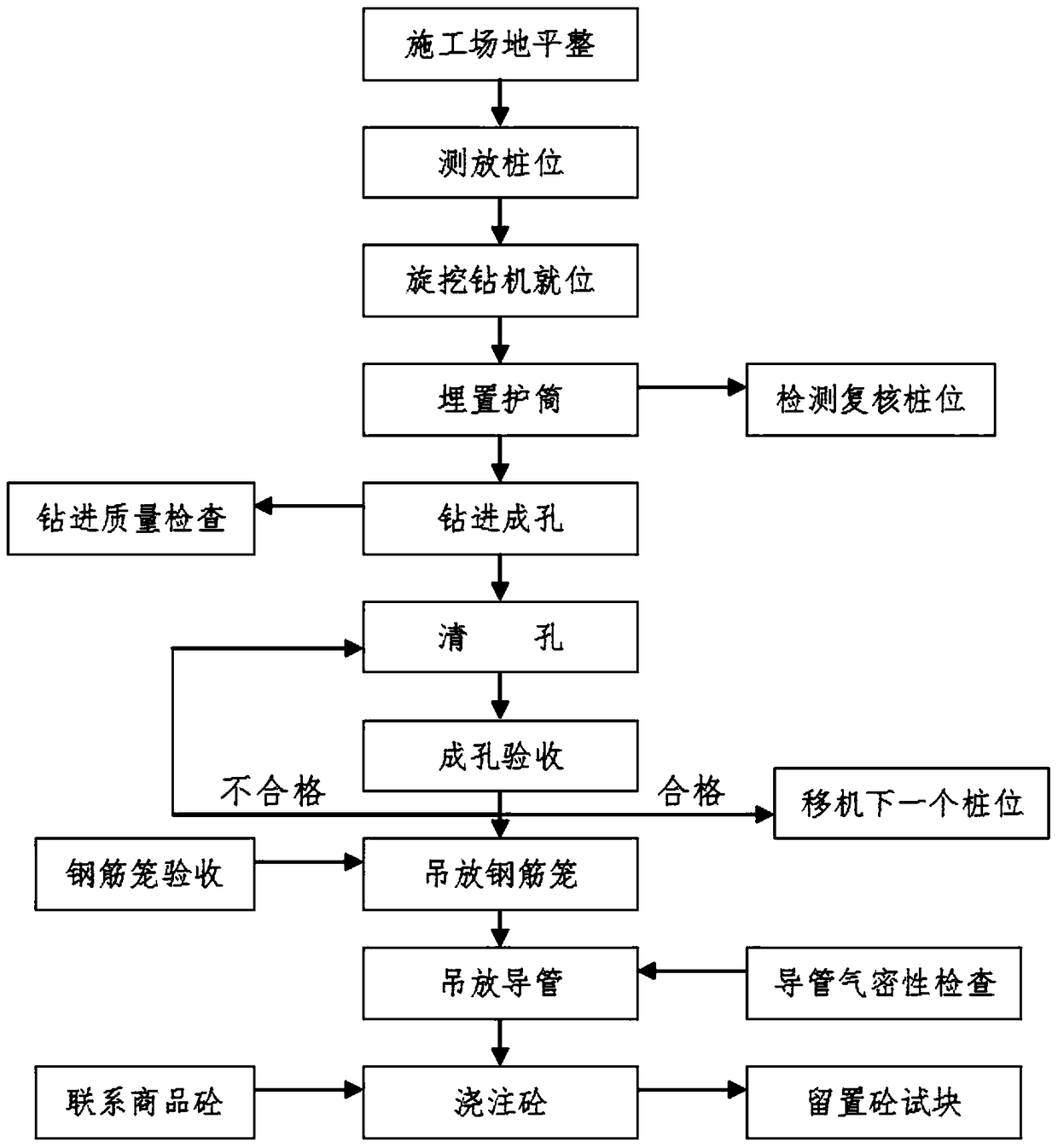

[0023] Example 1 Construction process flow and key points of operation

[0024] figure 1 This is the flow chart of the construction method of the present invention. The specific process flow and operation points are as follows:

[0025] 1. Construction preparation

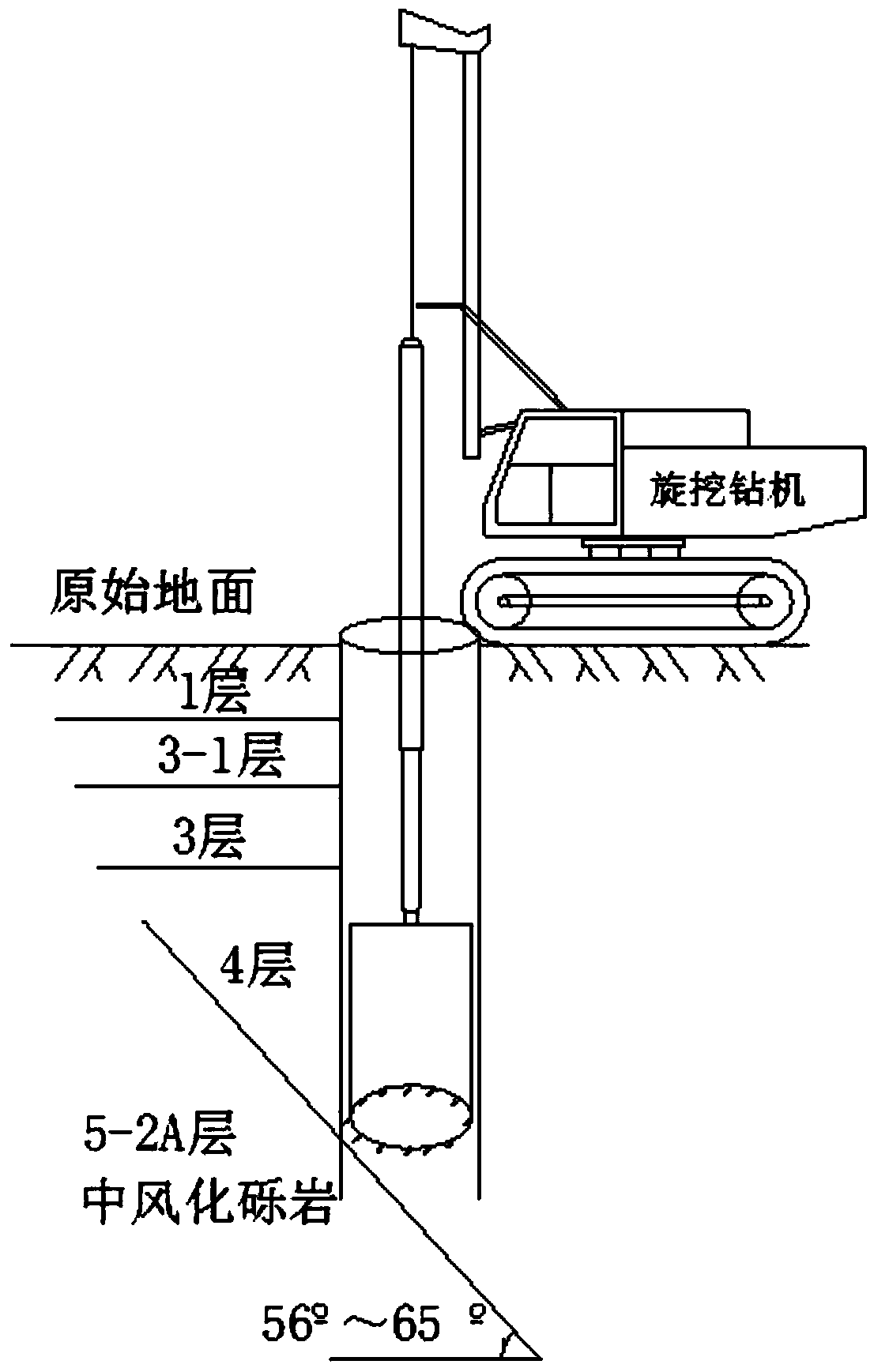

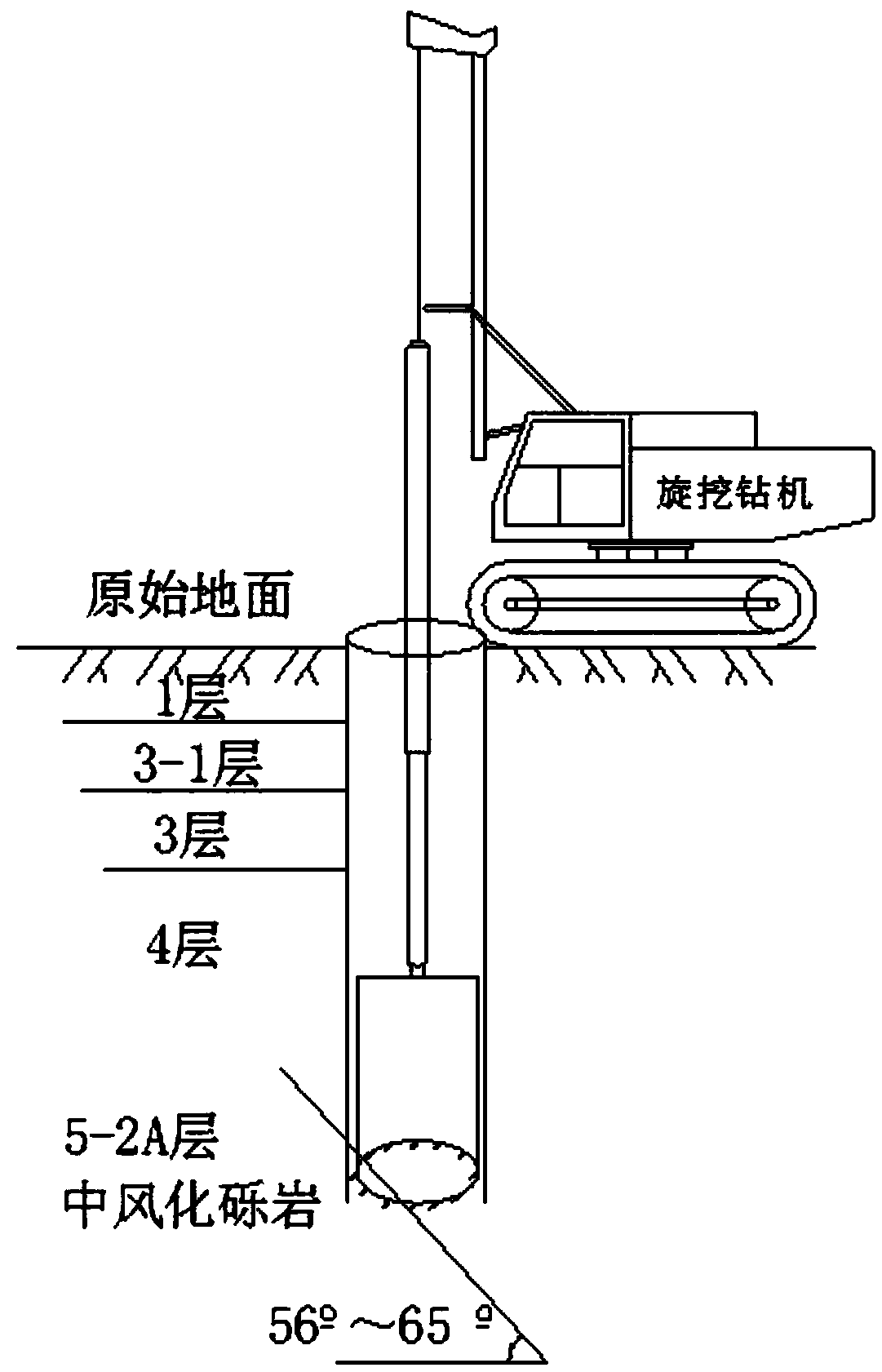

[0026] (1) Analyze the engineering geological conditions of soil and rock layers:

[0027] Before construction, study the engineering geology and hydrology, carefully analyze the geological survey report, and conduct a comprehensive analysis of the engineering geology. For construction in soil layers, soil properties such as hydrogeological structural parameters should be understood during analysis; for construction in rock layers, it is necessary to understand the cause and type of rocks, the size and occurrence of rock particles, rock structure and fracture development, etc.

[0028] (2) Configure construction machinery and equipment:

[0029] According to the different geological conditions of the project, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com