A rock-socketed construction technique for large-caliber pile foundations

A construction technology and large-diameter technology, which can be applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of transportation overrun construction requirements, high procurement and use costs, and the inability to realize the depth of rock-socketed pile foundations. Hole forming quality and hole forming efficiency, improving rock penetration efficiency and reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

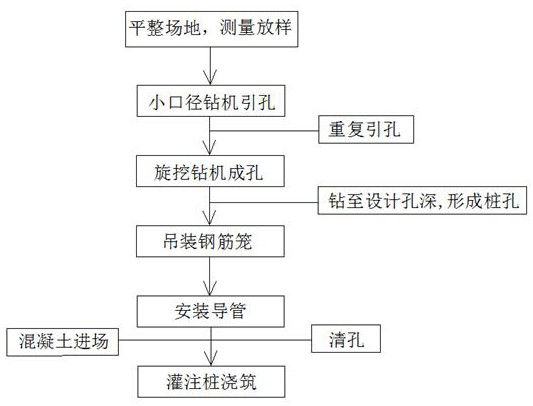

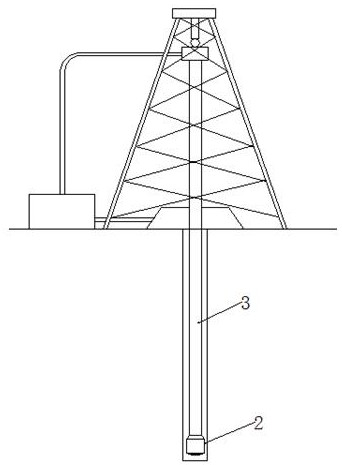

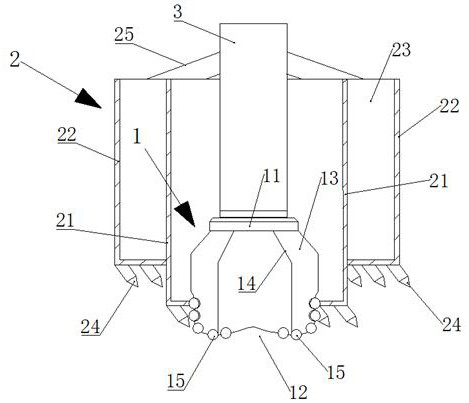

[0030] A rock-socketing construction technology for large-diameter pile foundations, which uses a combination of small-diameter drilling rigs and rotary drilling rigs for rock-socketing construction of large-diameter pile foundations. The role of the structure, the rotary drilling rig is equipped with a rotary drill bit 1 and a double-layer barrel drill 2, the rotary drill bit 1 has the function of cutting rock, and the double-layer barrel drill 2 can carry slag in the hole; the large-caliber pile foundation rock-socketing construction The process specifically includes the following steps:

[0031] S1. Level the site, measure and stake out; tamp the location where the small-diameter drilling rig and rotary drilling rig are placed and level the site; generally, the slope is not greater than 3°, and the ground endurance is not less than 100kPa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com