A method of large-diameter pile hole operation

A large-diameter, pile-hole technology, used in drilling equipment, earth-moving drilling, driving devices for rotary combined drilling, etc., to achieve the effects of short operation time, reduced waste, and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Embodiment, an efficient and pollution-free large-diameter pile hole operation method, comprising the following steps:

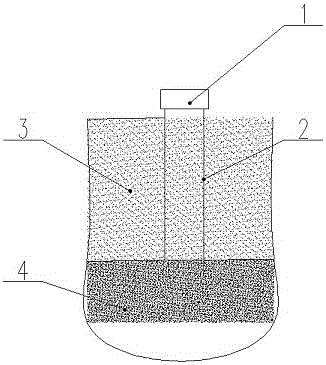

[0044] A. If figure 1 As shown, at the hole-forming position, firstly use the vibrating hammer 1 to press the retaining wall pipe 2 into the covering layer 3 until the rock 4, and remove the vibrating hammer 1;

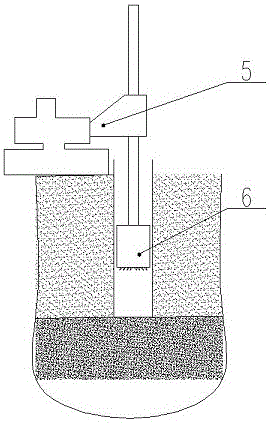

[0045] B. if figure 2 As shown, the rotary drilling rig 5 is in place, and the conventional rotary drilling bit 6 is used to dig out the soft covering layer in the retaining wall pipe 2, and the covering layer in the hole is cleaned up to the rock part 4;

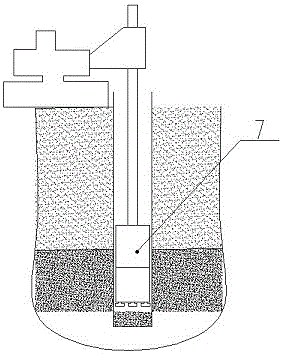

[0046] C. if image 3 As shown in the figure, the rotary drilling rig should replace the special cluster DTH hammer and carry out the rock-in operation until the pile hole meets the size requirements of the pile hole;

[0047] D. if Figure 4 As shown, take out the special cluster DTH hammer, and carry out the follow-up pile hole work such as lowering the reinforcement cage 8 and grouti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com