A device for preparing auxetic composite yarn through active wrapping of fine and hard low-elasticity yarn around thick and soft high-elasticity yarn

A technology of composite yarn and elastic yarn, which is applied in the direction of yarn, textiles and papermaking, etc. It can solve the problems of strong limitations of spinning methods, uneven yarn structure, unsuitability for continuous production, etc., and achieves easier control of yarn tension, yarn The effect of stable line tension, constant speed and stable supply and feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

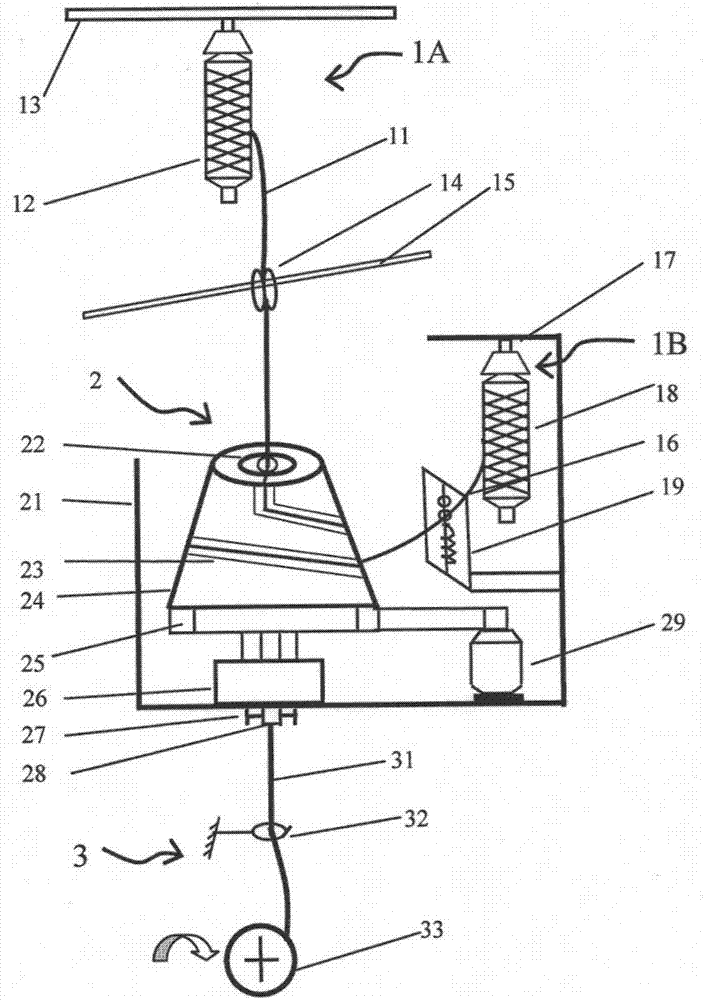

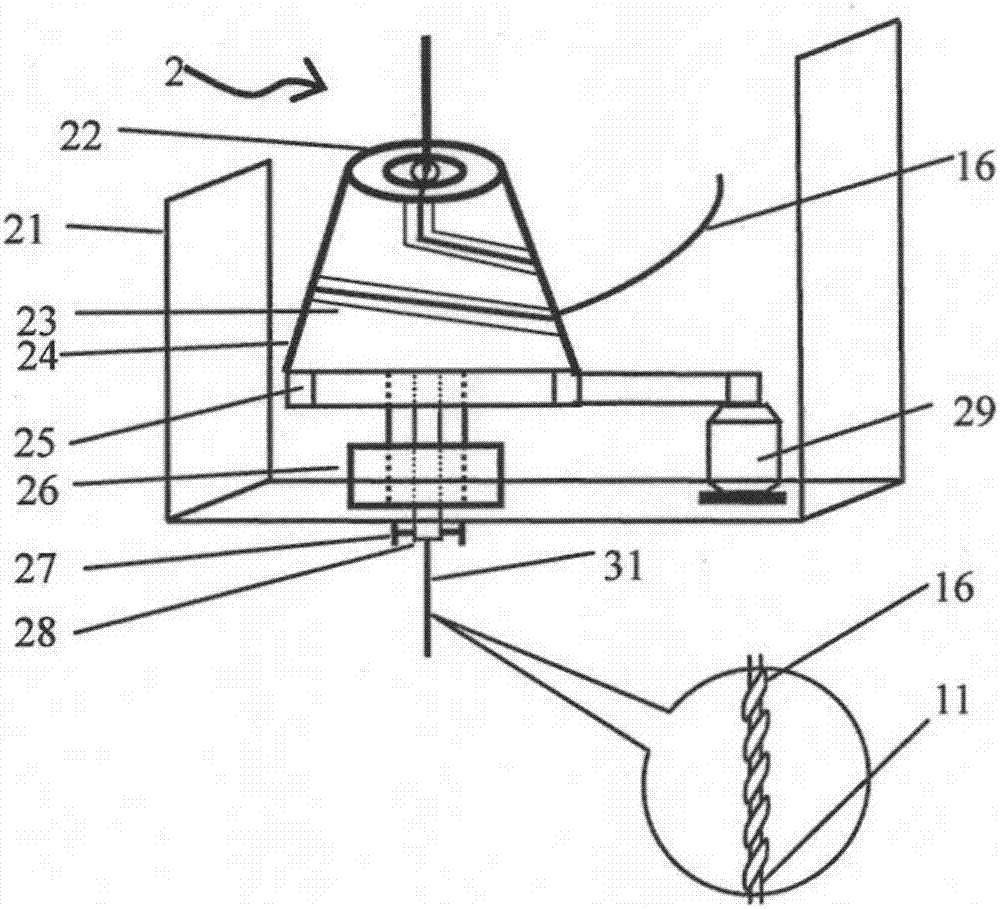

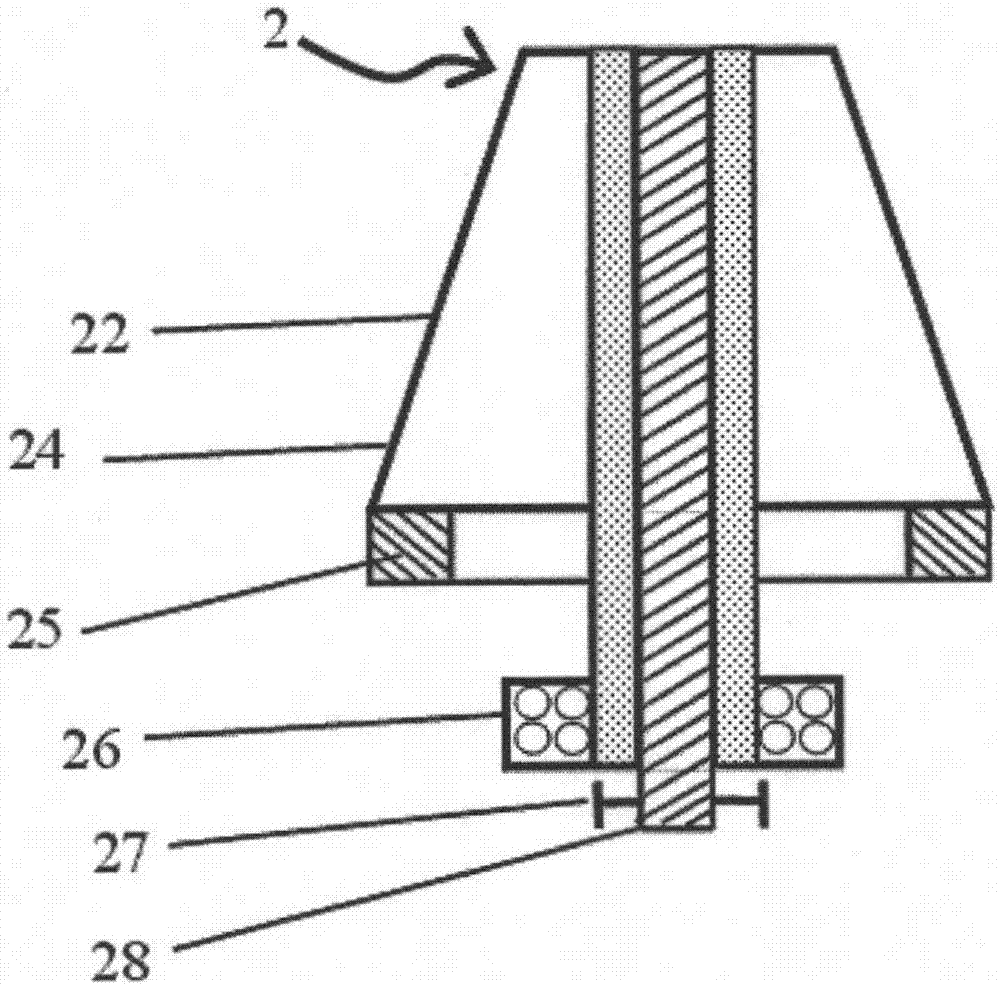

[0058] Embodiment 1 spandex / nylon auxetic composite yarn preparation

[0059] Spinning device and method for preparing auxetic composite yarn by actively winding thick, soft and high-elastic yarn with thin, hard and low-elastic yarn to implement spandex / nylon auxetic composite yarn, using spandex monofilament and nylon multifilament respectively As thick and soft high-elastic yarns and thin and hard low-elastic yarns, the spandex monofilament 11 unwound from the thick and soft high-elastic yarn bobbin 12 passes through the tension disc 14 and is pulled through the hollow tube 28 with a certain tension; The yarn 16 passes through the yarn guide hole 191 to the yarn guide groove 23 of the speed-controllable rotor 24; the nylon multifilament 16 follows the spiral yarn guide groove 23 on the surface of the speed-controllable rotor 24, and passes through the speed-controllable rotor 24. The rotation of the rotor cup 24 is output to the head end of the hollow tube, where it converge...

Embodiment 2

[0060] Example 2 Preparation of Spandex / UHMWPE Auxetic Composite Yarn

[0061] Spinning device and method for preparing auxetic composite yarn by actively winding thick, soft and high-elastic yarn with thin, hard and low-elastic yarn according to the present invention to prepare spandex / UHMWPE auxetic composite yarn, using spandex monofilament respectively and ultra-high molecular weight polyethylene multifilament as thick and soft high-elastic yarns and fine and hard low-elastic yarns. The rest of the operating steps are the same as in Example 1, and the specific process parameters are as shown in Table 1.

Embodiment 3

[0062] Example 3 Preparation of spandex / polyester high-strength yarn auxetic composite yarn

[0063] Spinning device and method for preparing auxetic composite yarn by actively winding thick, soft and high-elastic yarn with thin, hard and low-elastic yarn to implement spandex / polyester high-strength yarn auxetic composite yarn, using spandex monofilament and polyester respectively The high-strength yarn is used as thick and soft high-elastic yarns and fine and hard low-elastic yarns. The rest of the operating steps are the same as in Example 1, and the specific process parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com