Production process for recycling phenol residual liquid

A production process, phenol technology, applied in the field of production process for reuse of phenol residual liquid, can solve problems such as low purity of cumene, cumbersome production process, equipment corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

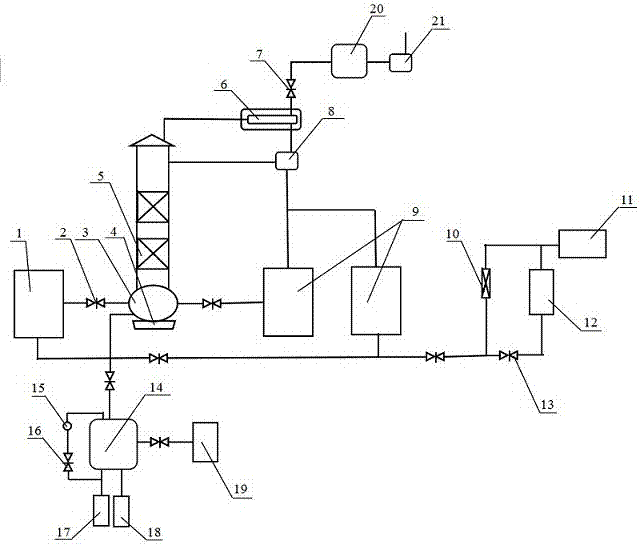

[0013] A production process for the reuse of phenol raffinate, which consists of a raw material storage tank, a transfer pump, a tower bottom kettle, an electric heater, a rectification tower, a condenser, a vacuum pump, a reflux ratio controller, a collection tank, a venturi mixer, Composed of phenol collection tank, extraction and separation tank, circulation pump, forced mixer, static mixer, pressure pump, emulsifier storage tank, fuel oil storage tank, emulsified fuel oil collection tank, cryogenic device, and activated carbon adsorption device; mainly divided into The process of crude distillation separation, rectification separation, phenol purification, waste gas treatment, and residue reuse. The process adopts batch production mode.

[0014] (1) Crude distillation separation: pump the phenol raffinate in the raw material tank to the bottom kettle, heat to 210°C to separate the mixed vapor of phenol and acetophenone, cool down through the condenser, and pass through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com