Device and process of using waste oil for coal flotation

A technology of waste oil and grease, applied in flotation, solid separation, etc., can solve the problem that the flotation process is suitable for less coal types, and achieve the effects of applying a wide range of coal types, solving high water content, and improving flotation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

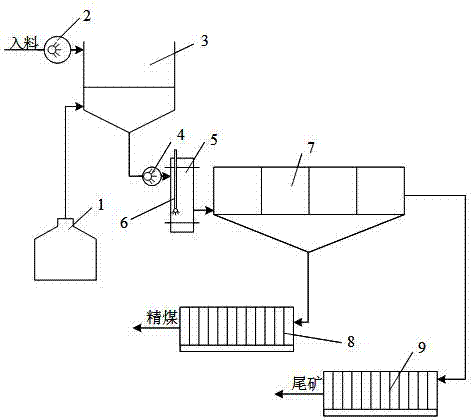

[0030] A device for coal flotation of waste oil, comprising a grease storage tank 1, a pulp pretreatment tank 3, a pretreatment cylinder 5, a flotation machine 7, and a filter press; the grease storage tank 1 is connected to the pulp pretreatment tank 3 , the pulp pretreatment tank 3 is provided with two feed ports: the pulp feed port and the grease feed port respectively, the bottom of the pulp pretreatment tank 3 is connected to the pretreatment cylinder 5, and the top side inlet end of the pretreatment cylinder 5 is provided with an atomizer Nozzle 4, the top is provided with an inlet pipe 6 inserted into the pulp outlet, the inlet pipe is the collector and foaming agent inlet pipe, the collector and foaming agent are mixed and enter from the inlet; the pretreatment cylinder 5 is connected to the flotation machine 7. Foam flotation is carried out in the flotation machine 7, the overflow outlet of the flotation machine is connected to the first filter press 8, and the underfl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com