Multi-element high-activity component carbon monoxide adsorbent as well as preparation method and application thereof

An active component, carbon monoxide technology, applied in the field of multi-active component carbon monoxide adsorbent and its preparation, can solve the problems of low carbon monoxide removal depth, small removal capacity, short service life, etc., and achieve the fluctuation of carbon monoxide content of raw material gas impurity Strong ability, high removal depth and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh Cu(NO 3 ) 2 , Zn(NO 3 ) 2 , Mn(NO 3 ) 2 , Ni(NO 3 ) 2 , Fe(NO 3 ) 3 , as shown in Table 1, stir and dissolve the above-mentioned substances in hot water at 65°C, inject the mixed solution into the reactor, and configure an excess of 20% of the aging agent Na 2 CO 3 The solution was slowly injected into the same reactor for 4h aging reaction, the reaction was controlled at 70°C and the pH value was 9-10, and then the reacted slurry was centrifuged to make a filter cake, dispersed and washed (water temperature 70°C) and repeated for 2 -3 times until the pH value of the slurry is 6-7, then dry the filter cake at low temperature and roast at 600°C for 5 hours, and granulate the activated oxide powder roasted at high temperature into columnar shape Ф5×(3~7) for later use. Take 200ml of catalyst respectively and put them into a stainless steel reactor of Ф40mm×2.5mm×300mm, and pass nitrogen gas at a space velocity of 10h -1Purge for 2h. Under the conditions ...

Embodiment 2~6

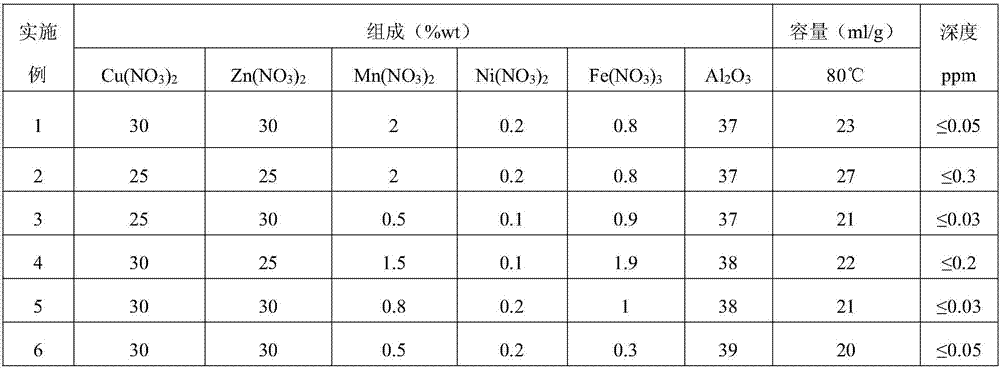

[0030] The preparation method and test method are the same as in Example 1, the difference is only in the composition of the adsorbent, see Table 1 for details.

[0031] The composition and evaluation result of table 1 embodiment 1-6 carbon monoxide adsorbent

[0032]

Embodiment 7

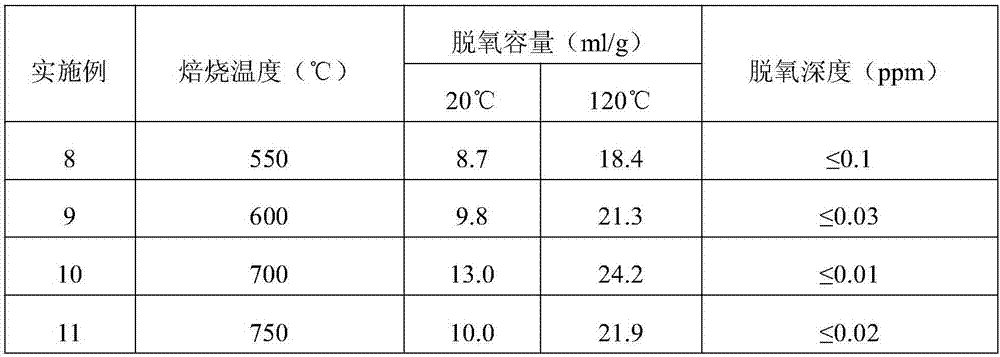

[0034] Weigh Cu(NO 3 ) 2 , Zn(NO 3 ) 2 , Mn(NO 3 ) 2 , Ni(NO 3 ) 2 , Fe(NO 3 ) 3 , as shown in Table 1, stir and dissolve the above-mentioned substances in hot water at 65°C, inject the mixed solution into the reactor, and configure an excess of 20% of the aging agent Na 2 CO 3 The solution was slowly injected into the same reactor for 4h aging reaction, the reaction was controlled at 70°C and the pH value was 9-10, and then the reacted slurry was centrifuged to make a filter cake, dispersed and washed (water temperature 70°C) and repeated for 2 -3 times until the pH value of the slurry is 6-7, then dry the filter cake at low temperature and roast at 600°C for 5 hours, and granulate the activated oxide powder roasted at high temperature into columnar shape Ф5×(3~7) for later use. Take 200ml of catalyst respectively and put them into a stainless steel reactor of Ф40mm×2.5mm×300mm, and pass nitrogen gas at a space velocity of 10h -1 Purge for 2h. Under the condition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com