Microwave and low-pressure superheated steam combined drying test apparatus and drying method

A technology of superheated steam and combined drying, which is applied in the direction of drying solid materials, heating devices, drying gas arrangement, etc., which can solve the problem that the product quality is too dependent on the environment and climate changes, and the thermal efficiency is generally only 30-60%. Inconsistent with internal cell shrinkage and other issues, to achieve the effect of accelerating water transfer speed, ensuring drying quality and drying uniformity, and ensuring drying uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

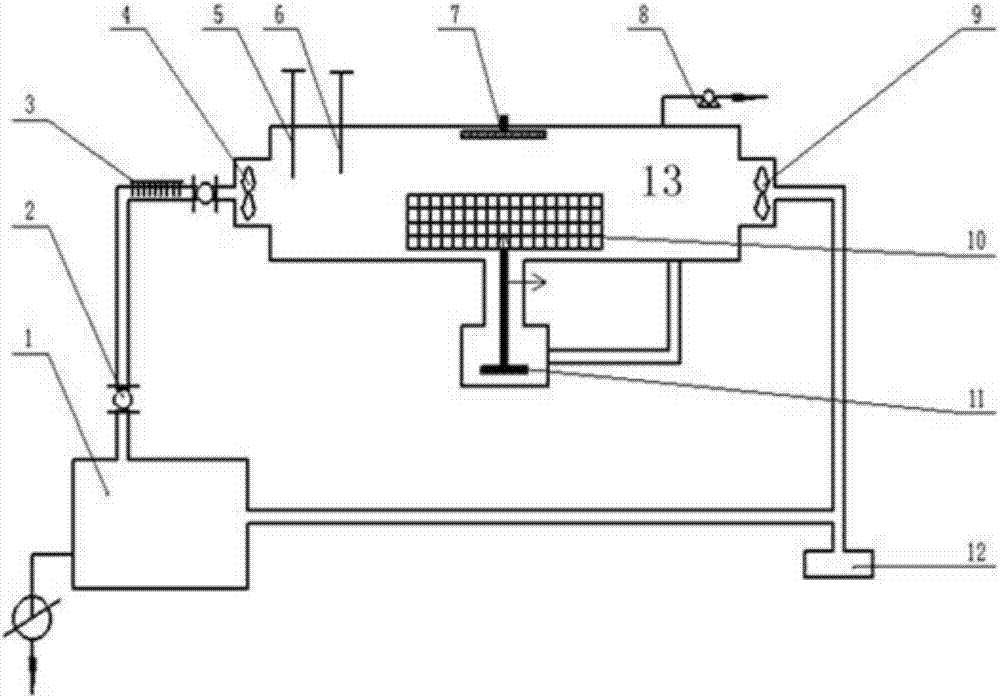

[0015] The present invention proposes a microwave-low pressure superheated steam combined drying test device and drying method. The specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0016] figure 1 Shown is a schematic diagram of the system structure of the microwave-low pressure superheated steam drying device. The microwave-low pressure superheated steam combination drying test device shown in the figure consists of a steam generator, a steam opening valve, a heater, an inlet fan, a wind speed sensor, a temperature sensor, a microwave generator, a vacuum pump, an outlet fan, a mesh material tray, A load cell, a flow valve and a drying box are composed; wherein, the steam generator 1 is respectively connected to the public node of the steam opening valve 2 and the outlet fan 9 and the flow valve 12; the outlet fan 9 is installed on the right end of the drying box 13, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com