Biocompatible water-core microcapsules and preparation method thereof

A biocompatible and external phase technology, applied in the field of biocompatible water-core microcapsules, can solve the problems of uneven size of microcapsules, difficulty in achieving effective control, and restrictions on the wide application of water-core microcapsules, and achieve good biological compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

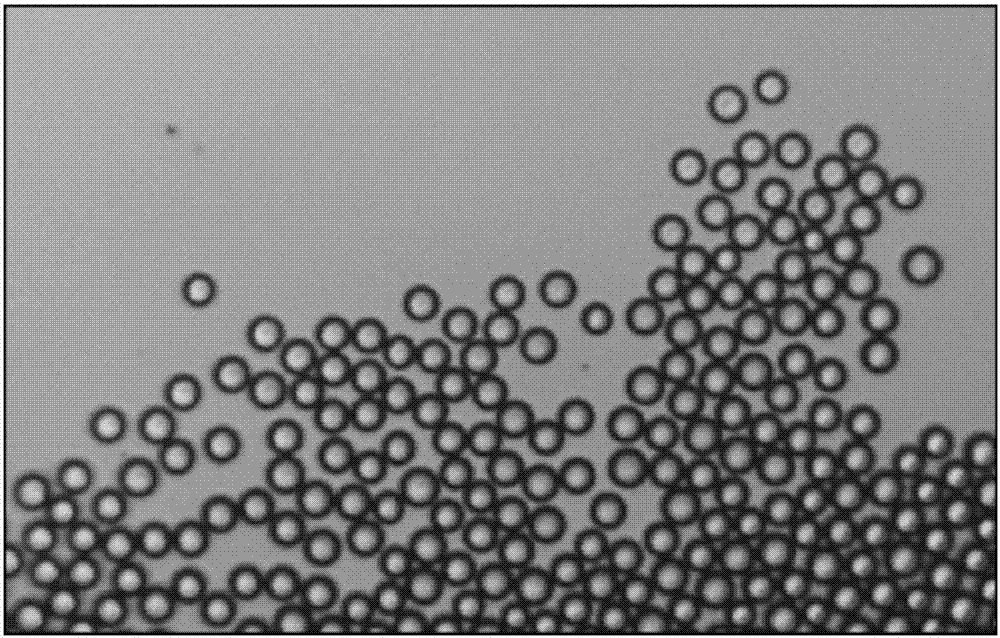

[0037] Example 1: Preparation of water core microcapsules with uniform size and diameter of about 10 μm

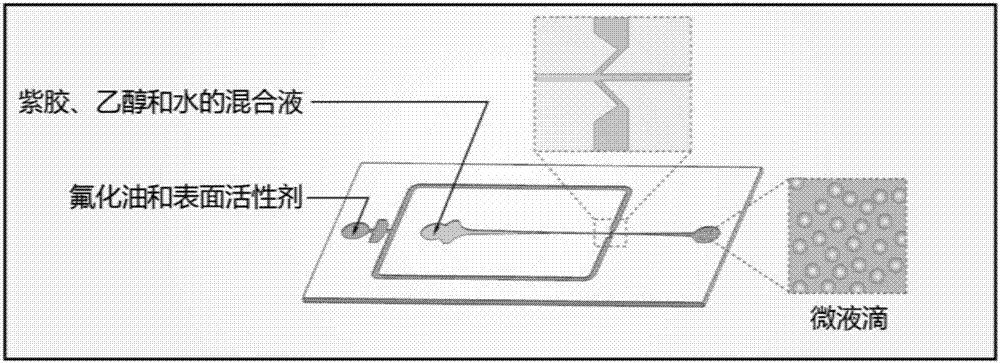

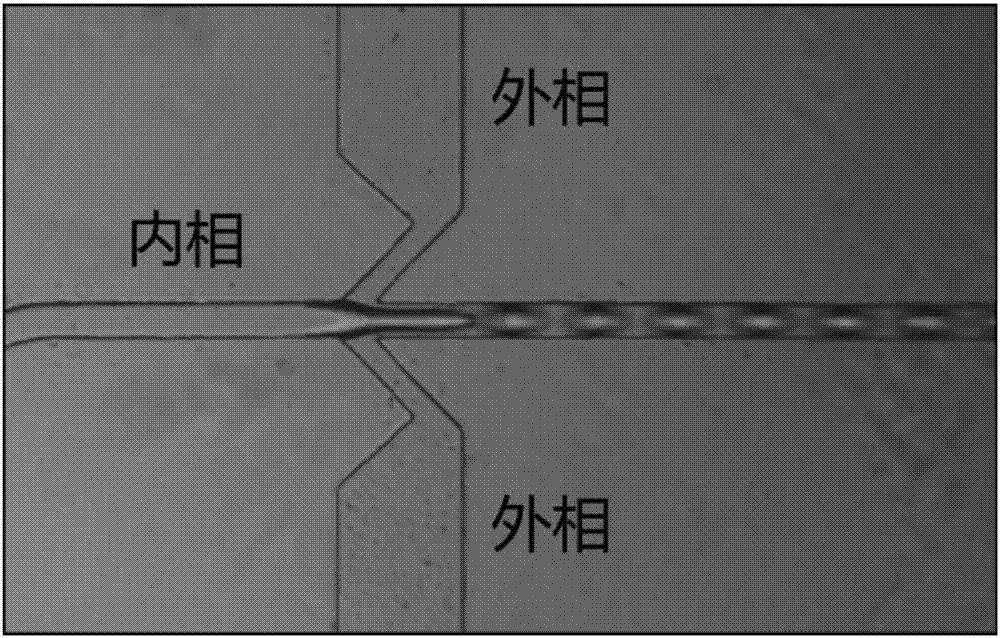

[0038] Refer to attached figure 1 , using the method of the present invention to prepare biocompatible water core microcapsules, the specific steps are as follows: (1) making of microfluidic device: the silicon wafer is cleaned and then dried; then a layer of SU- 8 photoresist; by pre-designing the prepared mask plate, the photoresist on the silicon wafer is partially exposed under the ultraviolet lamp; the silicon wafer is placed in the developer, and the unexposed part is removed, so as to obtain channel structure; mix the PDMS prepolymer and crosslinking agent at a mass ratio of 10:1, then pour the mixture on the silicon wafer, and then bake and cure; the cured PDMS will replicate the channel on the silicon wafer, through Oxygen plasma and heat treatment bond PDMS and glass substrates to make microfluidic chips. The chip channel is attached figure 1 As shown, there i...

Embodiment 2

[0042] Example 2: The release of hydrophilic molecules of different molecular weights encapsulated in water-core microcapsules over time

[0043] (1) Dissolve 2 mg of hydrophilic molecules (fluorescein or fluorescein dextran) in 1 ml of the internal phase obtained in Example 1, and use this solution as a new internal phase to prepare encapsulated hydrophilic molecules according to Example 1 water core microcapsules;

[0044] (2) The microcapsules wrapped with hydrophilic molecules prepared in (1) are dispersed in the water phase, and the concentration of the hydrophilic molecules in the water phase is measured by a UV-visible spectrophotometer as a function of time; Larger, the release rate of hydrophilic molecules is correspondingly reduced (such as attached Figure 7 shown).

Embodiment 3

[0045] Example 3: Polyelectrolyte layer-by-layer encapsulation of the microcapsules prepared by the present invention

[0046]In neutral water, due to the partial ionization of the carboxyl group of shellac on the surface of the microcapsule, the microcapsule is negatively charged and can adsorb a layer of positively charged polyelectrolyte. Because of the complex configuration of the polymer polyelectrolyte, the positive polyelectrolyte neutralizes the negative charge on the surface of the microcapsule while the excess positive charge makes the surface of the microcapsule positively charged, and then a layer of negatively charged polyelectrolyte can be adsorbed. In the same way, while the negative polyelectrolyte neutralizes the positive charge on the surface of the microcapsule, the excess negative charge makes the surface of the microcapsule negatively charged. Figure 8 (a) shown).

[0047] (1) Adsorb a layer of positively charged polyelectrolyte: dissolve polydiallyldime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com