A kind of anti-overcharge lithium battery electrolyte and preparation method thereof

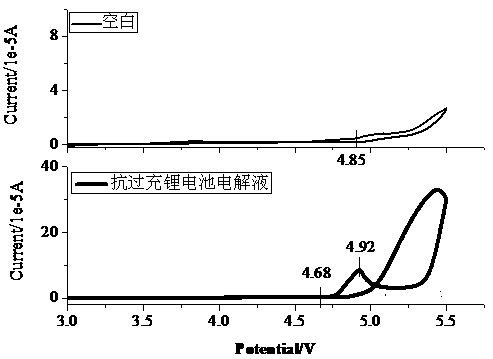

An electrolyte and lithium battery technology, applied in electrolytes, secondary batteries, and secondary battery repair/maintenance, etc., can solve problems such as safety accidents, cell bursting, and high gas production, and achieve strong applicability and increased safety. , the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

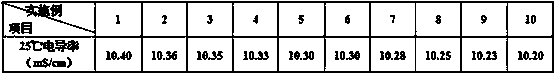

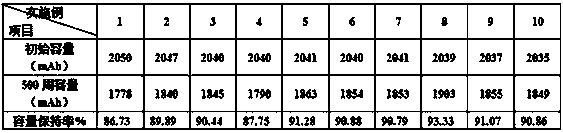

Embodiment 1

[0029] Add dimethyl carbonate (DMC), ethyl methyl carbonate (EMC), and ethylene carbonate (EC) in sequence according to the mass ratio of 1:1:1, and when the temperature drops to 10°C, ensure that the temperature is not higher than 10°C Slowly add lithium salt under low pressure to prepare an electrolyte solution with a lithium hexafluorophosphate concentration of 1mol / L, a lithium difluorooxalate borate concentration of 0.2mol / L, and a lithium bisfluorosulfonyl imide concentration of 0.1mol / L, and keep stirring until the solution is clear, and then fully Stir and transfer to a bottle filled with inert gas for storage.

Embodiment 2

[0031] Add dimethyl carbonate (DMC), ethyl methyl carbonate (EMC), and ethylene carbonate (EC) in sequence according to the mass ratio of 1:1:1, and when the temperature drops to 10°C, ensure that the temperature is not higher than 10°C Slowly add lithium salt under low pressure to prepare an electrolyte solution with a lithium hexafluorophosphate concentration of 1mol / L, a lithium difluorooxalate borate concentration of 0.2mol / L, and a lithium bisfluorosulfonyl imide concentration of 0.1mol / L, and keep stirring until the solution is clear; then follow The total mass of the electrolyte is calculated by adding 1% vinylene carbonate and 2% 1,3-propane sultone, then fully stirred, and transferred to a packaging bottle filled with inert gas for storage until use.

Embodiment 3

[0033] Add dimethyl carbonate (DMC), ethyl methyl carbonate (EMC), and ethylene carbonate (EC) in sequence according to the mass ratio of 1:1:1, and when the temperature drops to 10°C, ensure that the temperature is not higher than 10°C Slowly add lithium salt under low pressure to prepare an electrolyte solution with a lithium hexafluorophosphate concentration of 1mol / L, a lithium difluorooxalate borate concentration of 0.2mol / L, and a lithium bisfluorosulfonyl imide concentration of 0.1mol / L, and keep stirring until the solution is clear; then follow The total mass of the electrolyte is calculated by adding 2% 1,3-propane sultone, then fully stirred, and transferred to a packaging bottle filled with inert gas for storage until use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com