Novel micro-cantilever array cyclic scanning system

A technology of micro-cantilever and cyclic scanning, which is applied in the field of micro-beam scanning system, can solve the problems of data instability, different energy, and difficulty in signal recognition, and achieve the effect of avoiding light interference and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

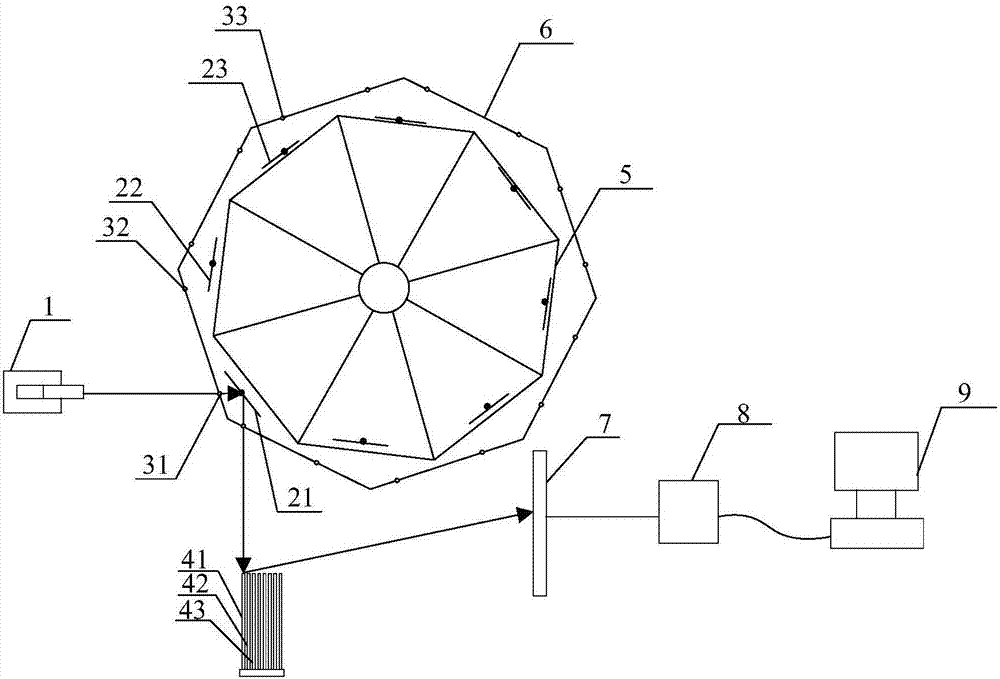

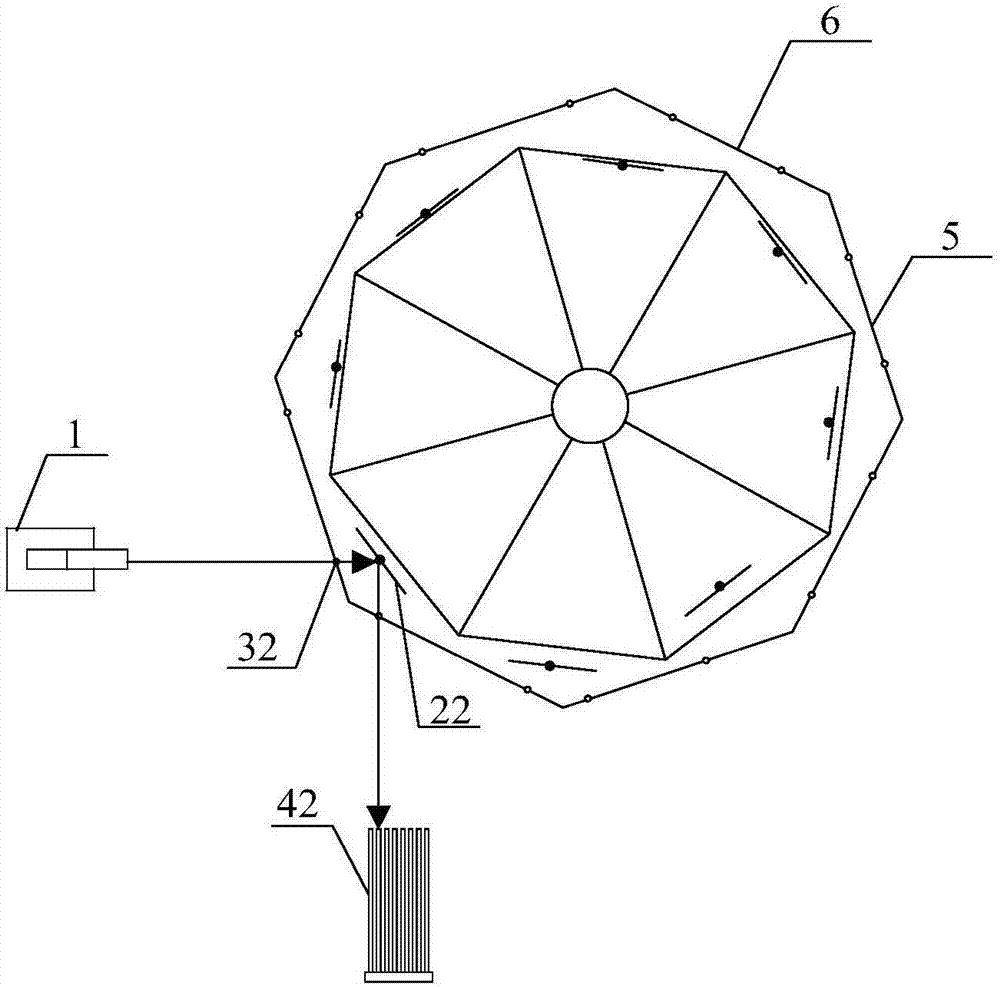

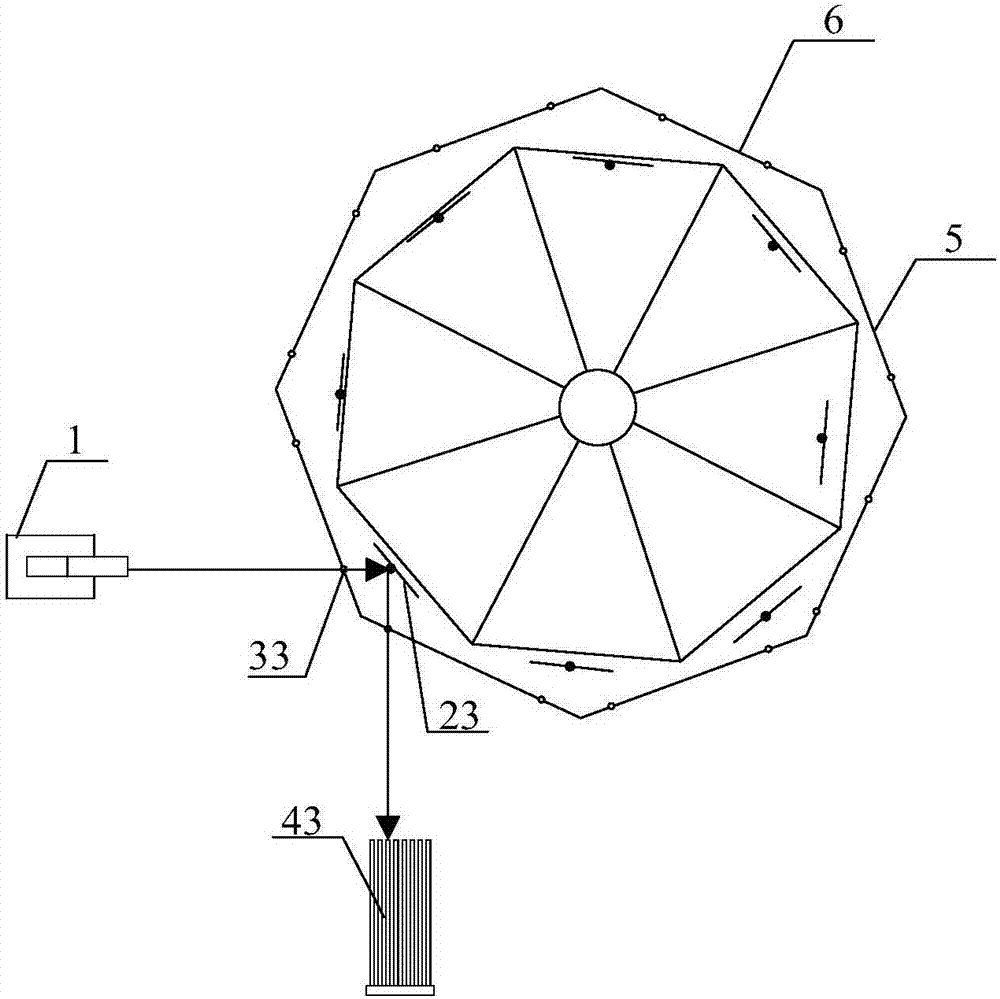

[0024] see figure 1 , figure 2 and image 3 , the structural form of the micro-cantilever beam array cyclic scanning system in the present embodiment is: the structural form of the cyclic scanning system composed of eight scanning units is set as:

[0025] The same fixed laser 1 is used as the shared laser light source of the eight scanning units. The laser 1 fixedly emits a laser beam horizontally. The laser 1 is a semiconductor laser, and the laser light source is a monochromatic light source with a wavelength of 632-780nm.

[0026] Eight micro-cantilever beams are used to form a micro-cantilever beam array, and eight plane mirrors are arranged correspondingly to the eight micro-cantilever beams; the eight plane mirrors are fixedly arranged on different positions of the same rotating platform 5; M plane mirrors Corresponding to a pair of incident and outgoing light holes in turn, drive the shading plate 6 and the rotating table 5 to rotate at the same speed at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com