Car lamp lampshade stress measurement loading device

A technology for stress detection and car lamp shades, applied in measuring devices, force/torque/work measuring instruments, and measurement of elastic deformation force through measuring gauges, can solve problems such as product damage, component damage, and inappropriateness, and achieve Easy to operate, easy to load, and avoid the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings of the description.

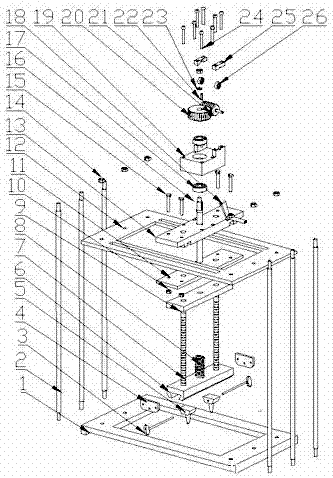

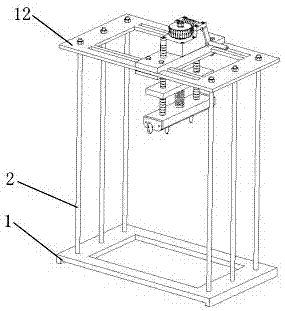

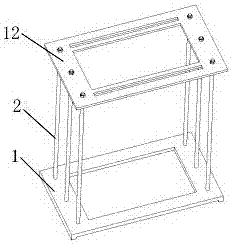

[0030] Such as Figure 1-5As shown in the figure, a loading device for stress detection of lampshades of lamps includes a base 1, a support column 2, an adjusting screw 3, a lower pressure plate end cover 4, a load pressure head 5, a lower pressure plate 6, a cylindrical guide rod 7, a spring 8, and an upper pressure plate 9. Small nut 10, lower adjustment slider 11, working plate 12, upper adjustment slider 13, large nut 14, small bolt 15, pressure screw shaft 16, large bearing 17, handle 18, unit seat 19, worm wheel 20, worm 21, key 22, gasket 23, large nut 24, bearing upper cover 25 and small bearing 26. Both ends of the support column 2 are threadedly connected with the base 1 and the working plate 12 respectively, the upper adjusting slider 13 and the lower adjusting slider 11 are installed on the working plate 12 through the small bolt 15, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com